Microsphere with multiple magnetic nano cores@gaps@porous shell structures and preparation method thereof

A magnetic nano-core technology, applied in the preparation of microspheres, the magnetism of organic materials/organic magnetic materials, nanotechnology, etc., can solve complex preparation methods, require high-temperature calcination, inert gas protection, and limit large-scale production and application and other problems, to achieve the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

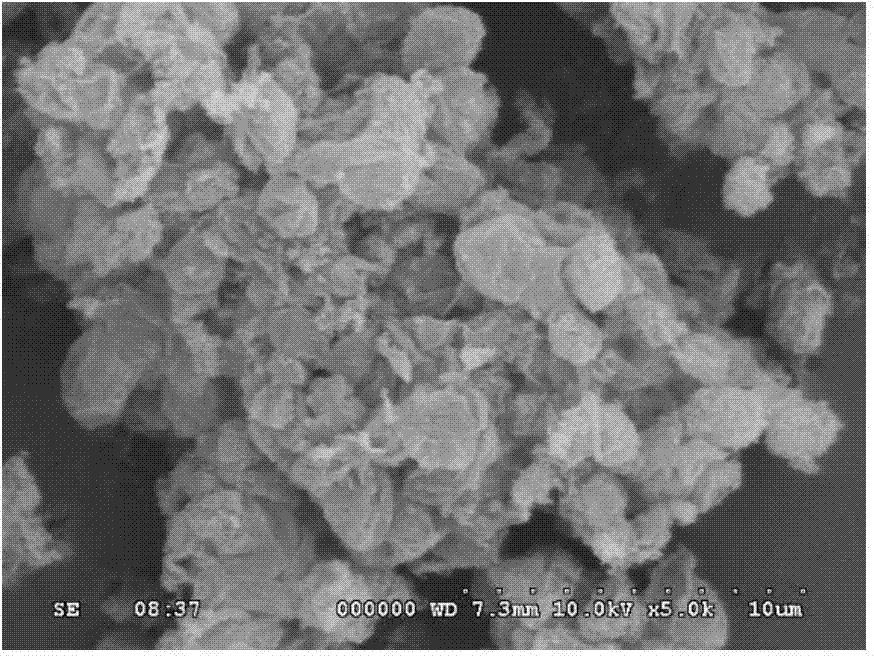

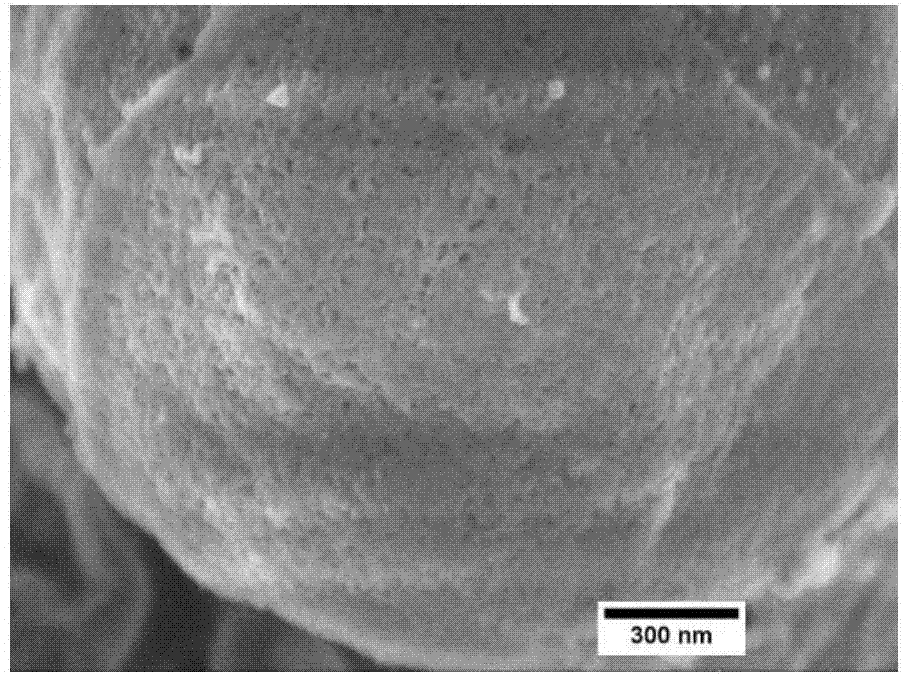

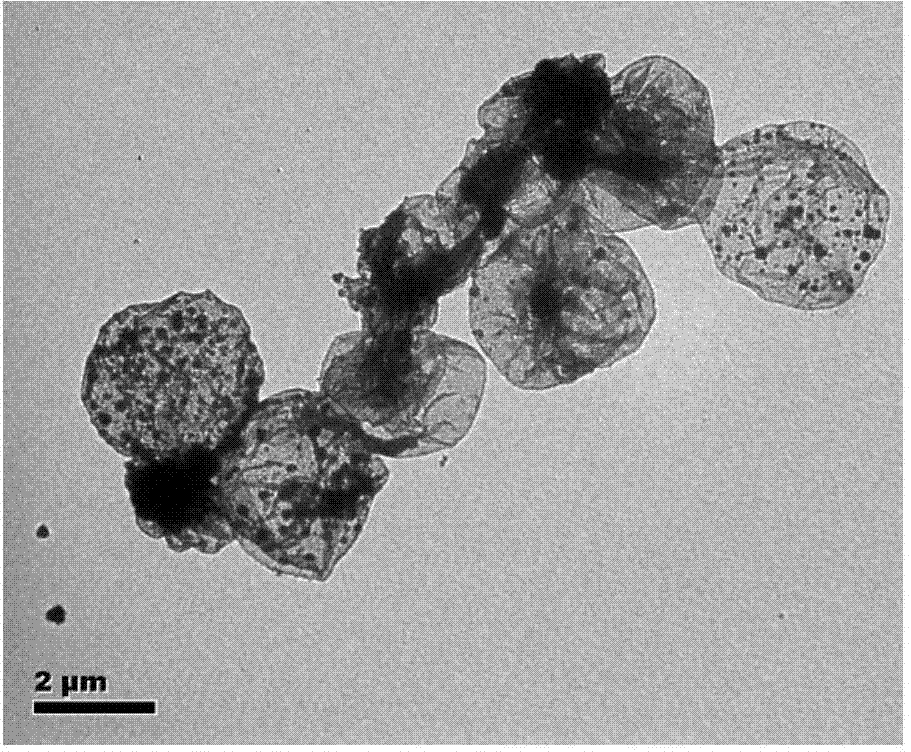

[0018] Dissolve 2g of ferric chloride in 100ml of deionized water, disperse 5g of chlorella dry powder in the prepared ferric chloride solution, place in a constant temperature water bath at 25°C and shake at 160rpm for 6h, then centrifuge the suspension at 5000rpm After 10 minutes, the obtained precipitate was repeatedly washed and centrifuged with deionized water for 4 times, and then the centrifugal precipitate was dispersed in 80ml of 8% sodium hydroxide solution and placed in a hydrothermal reaction kettle with a volume of 100ml and reacted at 105°C for 1h , after the reaction kettle is naturally cooled, take the suspension and centrifuge at 9000rpm for 8min, wash repeatedly with deionized water and centrifuge the precipitate 5 times, then disperse the precipitate in 80ml of deionized aqueous solution, and wash with 0.5mol / L hydrochloric acid or 0.5mol / L sodium hydroxide adjusted the pH of the system to be 9, and placed in a hydrothermal reactor with a volume of 100ml and ...

Embodiment 2

[0020] Dissolve 1g of ferric nitrate in 100ml of deionized water, disperse 5g of chlorella dry powder in the prepared ferric nitrate solution, place in a constant temperature water bath at 25°C and shake at 150rpm for 12h, then centrifuge the suspension at 5000rpm for 10min, The obtained precipitate was repeatedly washed and centrifuged with deionized water for 4 times, and then the centrifugal precipitate was dispersed in 80ml of 10% potassium hydroxide solution and placed in a hydrothermal reaction kettle with a volume of 100ml and reacted for 1h at 105°C. After the reaction kettle is naturally cooled, take the suspension and centrifuge it at 9000rpm for 8 minutes, wash it repeatedly with deionized water and centrifuge the precipitate 5 times, then disperse the precipitate in 80ml deionized aqueous solution, and wash it with 0.5mol / L hydrochloric acid or 0.5mol / L sodium hydroxide to adjust the pH of the system to 9, and place it in a hydrothermal reactor with a volume of 100...

Embodiment 3

[0022] Dissolve 6g of ferric ammonium citrate in 100ml of deionized water, disperse 5g of chlorella dry powder in the prepared ferric ammonium citrate solution, place it in a constant temperature water bath at 25°C and shake at 150rpm for 24h, then put the suspension in Centrifuge at 5000rpm for 10min, wash and centrifuge the obtained precipitate repeatedly with deionized water for 4 times, then disperse the centrifuged precipitate in 80ml of 10% ammonia solution and put it in a hydrothermal reaction kettle with a volume of 100ml for 2h at 105°C , after the reaction kettle is naturally cooled, take the suspension and centrifuge at 9000rpm for 8min, wash repeatedly with deionized water and centrifuge the precipitate 5 times, then disperse the precipitate in 80ml of deionized aqueous solution, and wash with 0.5mol / L hydrochloric acid or 0.5mol / L sodium hydroxide adjusted the pH of the system to be 10, and placed in a hydrothermal reaction kettle with a volume of 100ml to react fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com