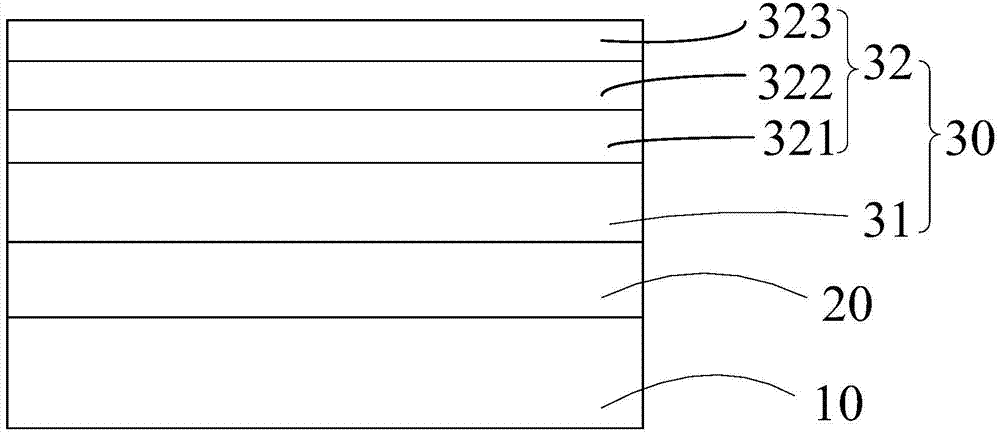

Organic light emitting diode device and preparation method thereof

An electroluminescence device and luminescence technology, which is applied in the direction of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as large light loss, achieve low work function, increase electron tunneling, and reduce light output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

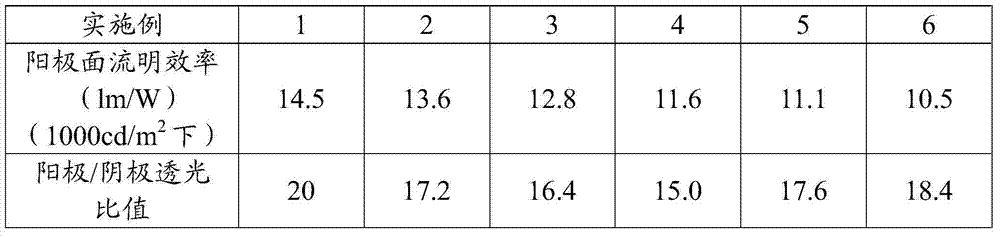

Embodiment 1

[0055] A method for preparing an organic electroluminescent device, comprising the following steps:

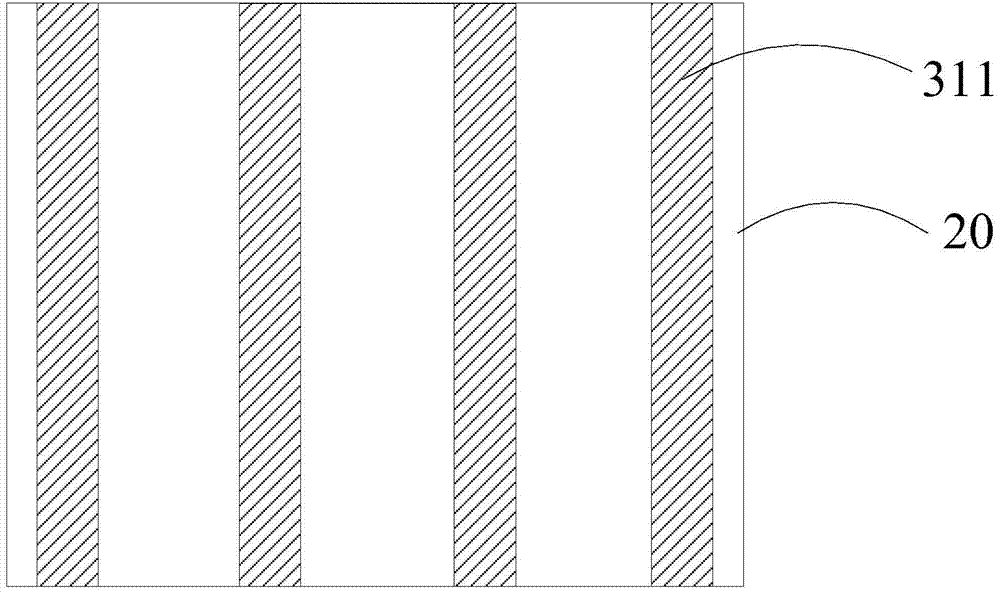

[0056] (1) Clean the transparent ITO glass substrate sequentially with detergent, deionized water, acetone, and ethanol, all of which are cleaned with an ultrasonic cleaner. Each wash is 5 minutes, repeated 3 times, and then dried in an oven. dry; and carry out surface activation treatment to the cleaned ITO glass to increase the oxygen content on the ITO surface and improve the work function of the ITO surface; the ITO thickness is 150nm;

[0057] (2) Prepare a light-emitting functional layer on the surface of the ITO glass substrate by vacuum thermal resistance evaporation, which includes a hole injection layer, a hole transport layer, a light-emitting layer, an electron transport layer, and an electron injection layer in sequence; specifically:

[0058] Preparation of the hole injection layer: the MoO 3 Doped into N,N'-diphenyl-N,N'-di(1-naphthyl)-1,1'-biphenyl-4,4'-diamin...

Embodiment 2

[0071] A method for preparing an organic electroluminescent device, comprising the following steps:

[0072] (1) Clean the transparent ITO glass substrate sequentially with detergent, deionized water, acetone, and ethanol, all of which are cleaned with an ultrasonic cleaner. Each wash is 5 minutes, repeated 3 times, and then dried in an oven. dry; and carry out surface activation treatment to the cleaned ITO glass to increase the oxygen content on the ITO surface and improve the work function of the ITO surface; the ITO thickness is 120nm;

[0073] (2) Prepare a light-emitting functional layer on the surface of the ITO glass substrate by vacuum thermal resistance evaporation, which includes a hole injection layer, a hole transport layer, a light-emitting layer, an electron transport layer, and an electron injection layer in sequence; specifically:

[0074] Preparation of the hole injection layer: the WO 3 Doped into 4,4’,4’’-tris(carbazol-9-yl)triphenylamine (TCTA) as hole in...

Embodiment 3

[0085] A method for preparing an organic electroluminescent device, comprising the following steps:

[0086] (1) Clean the transparent ITO glass substrate sequentially with detergent, deionized water, acetone, and ethanol, all of which are cleaned with an ultrasonic cleaner. Each wash is 5 minutes, repeated 3 times, and then dried in an oven. dry; and carry out surface activation treatment to the ITO glass after cleaning, to increase the oxygen content on the ITO surface, improve the work function of the ITO surface; ITO thickness 100nm;

[0087] (2) Prepare a light-emitting functional layer on the surface of the ITO glass substrate by vacuum thermal resistance evaporation, which includes a hole injection layer, a hole transport layer, a light-emitting layer, an electron transport layer, and an electron injection layer in sequence; specifically:

[0088] Preparation of the hole injection layer: the V 2 o 5 Doped into 4,4’-bis(9-carbazole)biphenyl (CBP) as hole injection laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com