Chitosan microsphere preparation method

A technology of chitosan microspheres and chitosan, which is applied in the direction of microsphere preparation, microcapsule preparation, chemical instruments and methods, etc., can solve problems such as easy adhesion of microsphere products, and achieve simple post-processing procedures and high particle size The effect of non-sticking and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

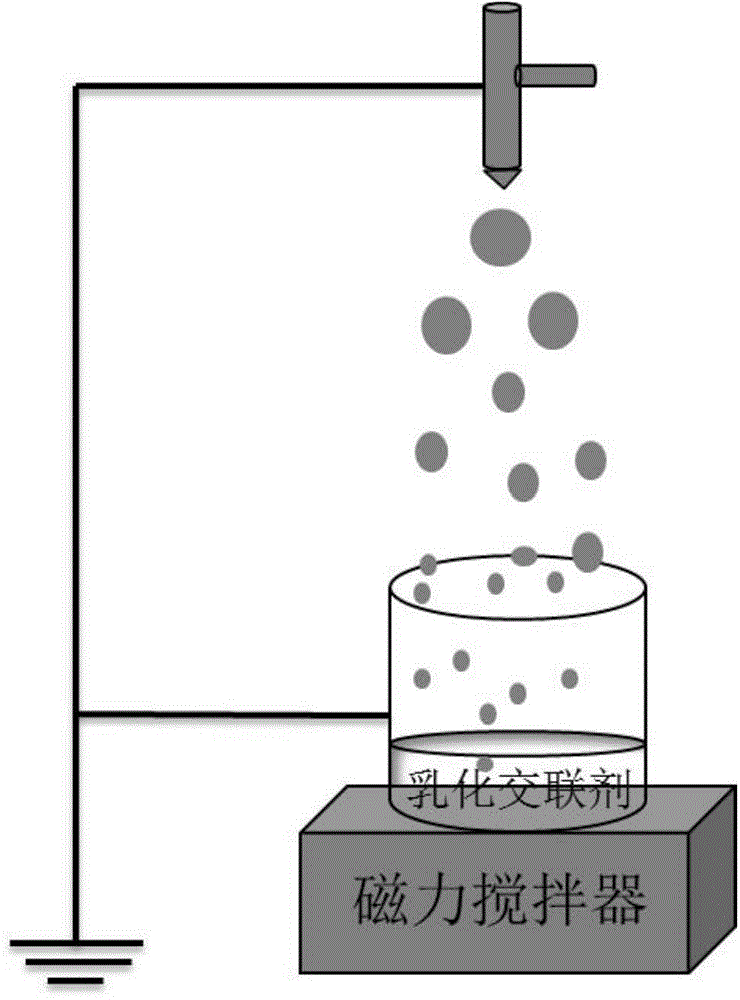

[0023] A preparation method of chitosan microspheres, comprising the following steps:

[0024] 1) Chitosan solution preparation: Chitosan (Mw=100000g·mol -1 ) was dissolved in formic acid aqueous solution (deionized water and formic acid volume ratio is 90 / 10), the preparation mass fraction is 2wt% chitosan solution, stirred at room temperature until fully dissolved, standing to remove air bubbles, to obtain uniform and transparent chitosan sugar solution;

[0025] 2) Preparation of emulsified cross-linking agent: Stir 20 mL of a mixture of liquid paraffin and petroleum ether with a volume ratio of 7 / 5 evenly, add 1 g of Tween-80 and 3 mL of glutaraldehyde in turn, and stir evenly to obtain emulsified cross-linked agent;

[0026] 3) Preparation of chitosan microspheres: at room temperature, the polymer solution in step 1) was placed in a 5mL syringe, and the extrusion rate was controlled by a micro-injection pump to be 0.1mL / h; the electrospray voltage was 8kV, The distance...

Embodiment 2

[0029] A preparation method of chitosan microspheres, comprising the following steps:

[0030] 1) Chitosan solution preparation: chitosan (Mw=200000g·mol -1 ) was dissolved in formic acid aqueous solution (deionized water and formic acid volume ratio is 50 / 50), the preparation mass fraction is 1wt% chitosan solution, stirred at room temperature until fully dissolved, standing to remove air bubbles, to obtain uniform and transparent chitosan sugar solution;

[0031] 2) Preparation of emulsified cross-linking agent: Stir 50 mL of a mixture of liquid paraffin and petroleum ether with a volume ratio of 7 / 5 evenly, add 2 g of Tween-80 and 0.5 mL of glutaraldehyde in turn, and stir evenly to obtain emulsified cross-linking agent. joint agent;

[0032] 3) Preparation of chitosan microspheres: at room temperature, the polymer solution in step 1) was placed in a 5mL syringe, and the extrusion rate was controlled by a micro-injection pump to be 1.0mL / h; the electrospray voltage was 15...

Embodiment 3

[0034] A preparation method of chitosan microspheres, comprising the following steps:

[0035] 1) Chitosan solution preparation: chitosan (Mw=120000g·mol -1 ) was dissolved in acetic acid aqueous solution (deionized water and acetic acid volume ratio are 90 / 10), the preparation mass fraction is 1.5wt% chitosan solution, stirred at room temperature until fully dissolved, standing to remove air bubbles, to obtain a uniform transparent shell polysaccharide solution;

[0036] 2) Preparation of emulsified cross-linking agent: Stir 30 mL of a mixture of liquid paraffin and petroleum ether with a volume ratio of 7 / 5 evenly, add 1 g of Tween-80 and 1 mL of glutaraldehyde in turn, and stir evenly to obtain emulsified cross-linked agent;

[0037] 3) Preparation of chitosan microspheres: at room temperature, the polymer solution in step 1) was placed in a 5mL syringe, and the extrusion rate was controlled by a micro-injection pump to be 0.5mL / h; the electrospray voltage was 10kV, The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com