Organically-coated magnetic nano adsorber and preparation method and application thereof

A magnetic nanometer and magnetic nanoparticle technology, which is applied in chemical instruments and methods, adsorption water/sewage treatment, inorganic chemistry, etc., can solve the problems of no magnetic adsorbent, etc., and achieve the improvement of adsorption capacity, selectivity, and enrichment multiple Large, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

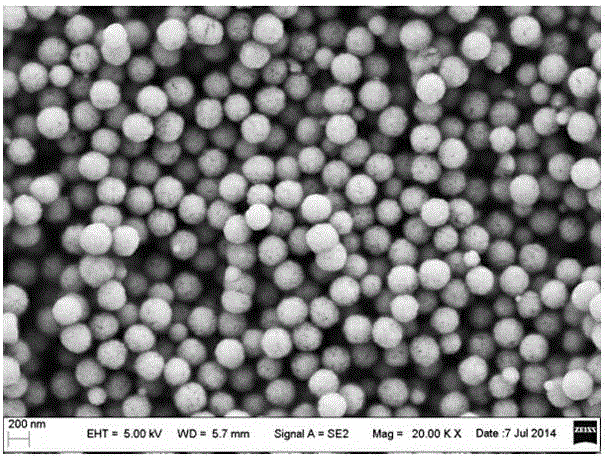

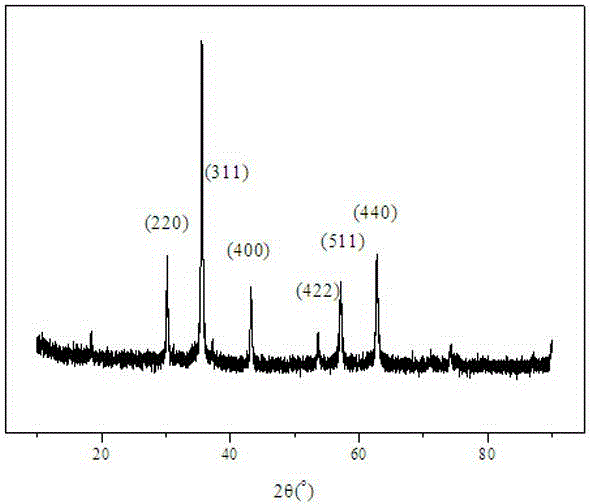

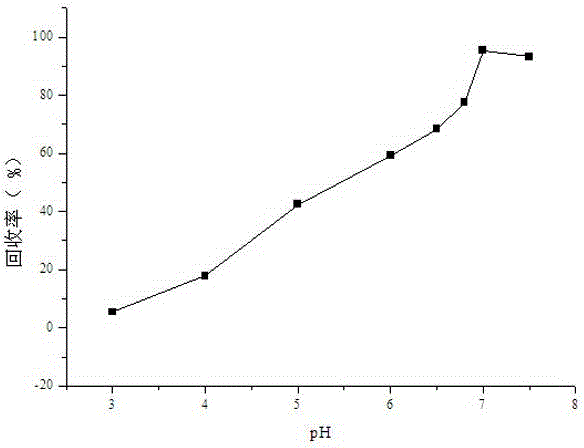

[0024] Preparation of Organically Encapsulated Magnetic Nanosorbents

[0025] (1) Preparation of magnetic core: quickly and accurately weigh 2.0 g FeCl 3 ·6H 2 O was dissolved in 60 mL of ethylene glycol, and 5.0 g of anhydrous sodium acetate was added and mixed in a beaker. Stir the mixed solution with a magnetic stirrer, move it into a water bath environment at 50°C, and continue to stir vigorously for 20 minutes until the solute is completely dissolved to form a uniform orange solution. Seal the solution in a 100 mL polytetrafluoroethylene reactor and lock it with a stainless steel jacket. Tight, placed in a 190 ° C reaction furnace to heat the reaction for 6 hours. After taking it out, cool it to room temperature in the air, remove the reaction product, and wash it several times with absolute ethanol and deionized water respectively to remove residual substances. Dry in a vacuum oven at 50 °C for 24 h to obtain magnetic nanoparticles.

[0026] (2) Organically encapsula...

Embodiment 2

[0028] Preparation of Organically Encapsulated Magnetic Nanosorbents

[0029] (1) Preparation of magnetic core: quickly and accurately weigh 2.5 g FeCl 3 ·6H 2 O was dissolved in 70 mL of ethylene glycol, and 6.0 g of anhydrous sodium acetate was added and mixed in a beaker. The mixed solution was stirred with a magnetic stirrer, and moved into a 60°C water bath environment, and continued to stir vigorously for 30 min until the solute was completely dissolved to form a uniform orange solution. The solution was sealed in a 100 mL polytetrafluoroethylene reaction kettle with a stainless steel jacket Lock it tightly and place it in a reaction furnace at 210°C for 10 h. After taking it out, cool it to room temperature in the air, remove the reaction product, and wash it several times with absolute ethanol and deionized water respectively to remove residual substances. Dry in a vacuum oven at 50 °C for 24 h to obtain magnetic nanoparticles.

[0030] (2) Organically encapsulated...

Embodiment 3

[0032] Preparation of Organically Encapsulated Magnetic Nanosorbents

[0033] (1) Preparation of magnetic core: quickly and accurately weigh 2.2g FeCl 3 ·6H 2 O was dissolved in 65 mL of ethylene glycol, and 5.5 g of anhydrous sodium acetate was added to the beaker and mixed. The mixed solution was stirred with a magnetic stirrer, and moved into a water bath environment at 55°C, and continued to stir vigorously for 25 minutes until the solute was completely dissolved to form a uniform orange solution. Seal the solution in a 100 mL polytetrafluoroethylene reaction kettle and lock it with a stainless steel jacket Tight, placed in a 200 ° C reaction furnace to heat the reaction for 8 hours. After taking it out, cool it to room temperature in the air, remove the reaction product, and wash it several times with absolute ethanol and deionized water respectively to remove residual substances. Dry in a vacuum oven at 50 °C for 24 h to obtain magnetic nanoparticles.

[0034] (2) Or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com