Method for determining cumene hydroperoxide impurity

A technology for cumene hydrogen peroxide and impurities, which is applied in the field of chemical analysis, can solve problems such as the limit detection method of cumene hydrogen peroxide that has not been seen before, and achieves the effects of reliable separation, convenient operation and strong accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

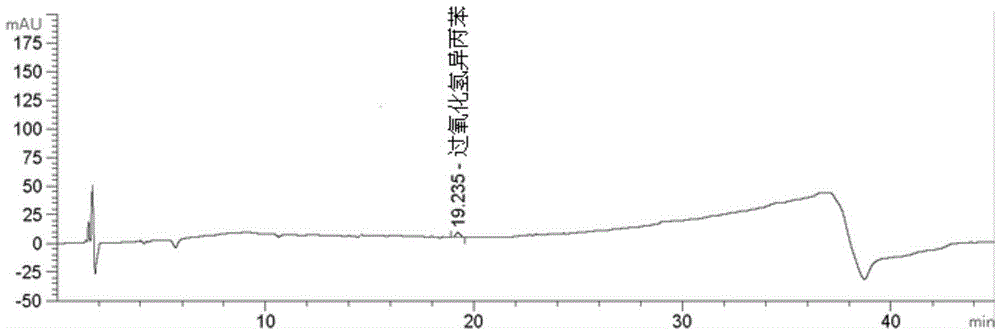

Embodiment 1

[0051] Instrument: Agilent1260 high performance liquid chromatography, 1210 ultraviolet detector

[0052] Chromatographic column: a chromatographic column (150×4.6mm, 5μm) filled with siloxane-bonded silica gel;

[0053] Mobile phase A: triethylamine aqueous solution (adjust pH to 6.2 with phosphoric acid)

[0054] Mobile Phase B: Acetonitrile

[0055] Gradient elution:

[0056] time / min

Mobile phase A / %

Mobile phase B / %

0

85

15

3

85

15

35

45

55

36

85

15

45

85

15

[0057] Flow rate: 1.0ml / min

[0058] Detection wavelength: 210nm

[0059] Column temperature: 30°C

[0060] Injection volume: 10μl

[0061] Diluent: acetonitrile: triethylamine aqueous solution (adjust pH to 10-11 with phosphoric acid) = 40:60 (v / v)

[0062] Run time: 45 minutes

[0063] Experimental steps:

[0064] Need testing solution: take by weighing dexlansoprazole crude drug 1.0014g and put 10mL measuri...

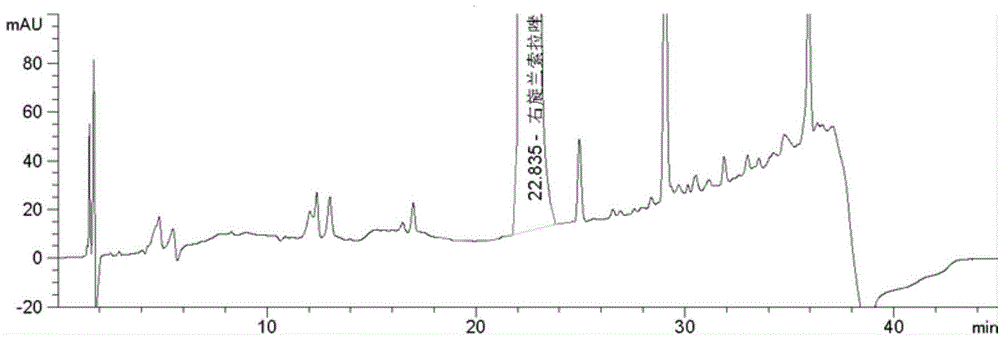

Embodiment 2

[0071] Instrument: Agilent1260 high performance liquid chromatography, 1210 ultraviolet detector

[0072] Chromatographic column: a chromatographic column (150×4.6mm, 5μm) filled with siloxane-bonded silica gel;

[0073] Mobile phase A: triethylamine aqueous solution (adjust pH to 5.5 with phosphoric acid)

[0074] Mobile Phase B: Acetonitrile

[0075] Gradient elution:

[0076] time / min

Mobile phase A / %

Mobile phase B / %

0

85

15

3

85

15

35

45

55

36

85

15

45

85

15

[0077] Flow rate: 1.2ml / min

[0078] Detection wavelength: 210nm

[0079] Column temperature: 30°C

[0080] Injection volume: 10μl

[0081] Diluent: acetonitrile: triethylamine aqueous solution (adjust pH to 10-11 with phosphoric acid) = 40:60 (v / v)

[0082] Run time: 45 minutes

[0083] Experimental steps:

[0084] Cumyl hydroperoxide reference stock solution: use a diluent to prepare a solution with a concen...

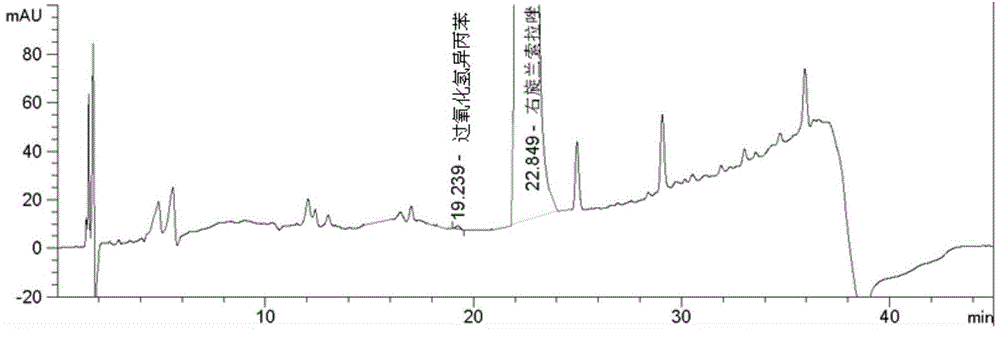

Embodiment 3

[0090] Instrument: Agilent1260 high performance liquid chromatography, 1210 ultraviolet detector

[0091] Chromatographic column: a chromatographic column (150×4.6mm, 5μm) filled with siloxane-bonded silica gel;

[0092] Mobile phase A: triethylamine aqueous solution (adjust pH to 7.0 with phosphoric acid)

[0093] Mobile Phase B: Methanol

[0094] Gradient elution:

[0095] time / min

Mobile phase A / %

Mobile phase B / %

0

85

15

3

85

15

35

45

55

36

85

15

45

85

15

[0096] Flow rate: 0.8ml / min

[0097] Detection wavelength: 210nm

[0098] Column temperature: 30°C

[0099] Injection volume: 10μl

[0100] Diluent: acetonitrile: triethylamine aqueous solution (adjust pH to 10-11 with phosphoric acid) = 40:60 (v / v)

[0101] Run time: 45 minutes

[0102] Experimental steps:

[0103] Cumyl hydroperoxide reference stock solution: use a diluent to prepare a solution with a concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com