Method for preparing anti-pollution polysulfone porous membrane by self-assembling immobilization of metal ions

A technology for immobilizing metal ions and metal ions, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. The effect of strong anti-pollution ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

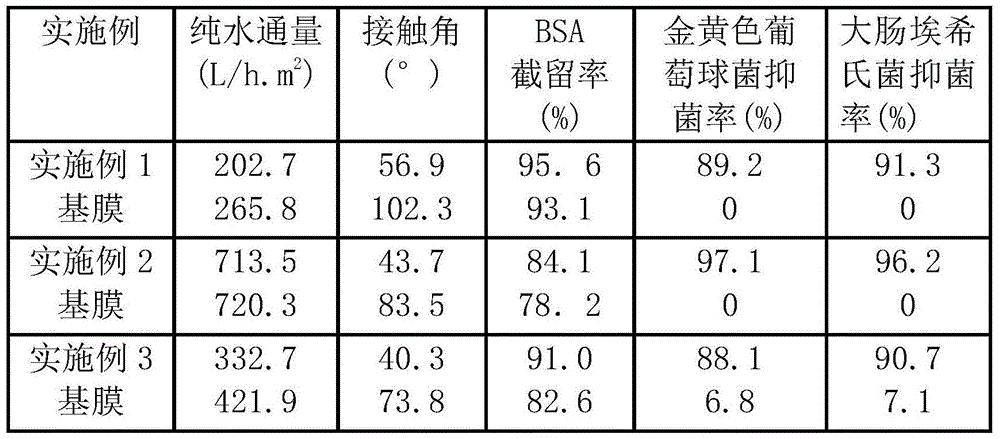

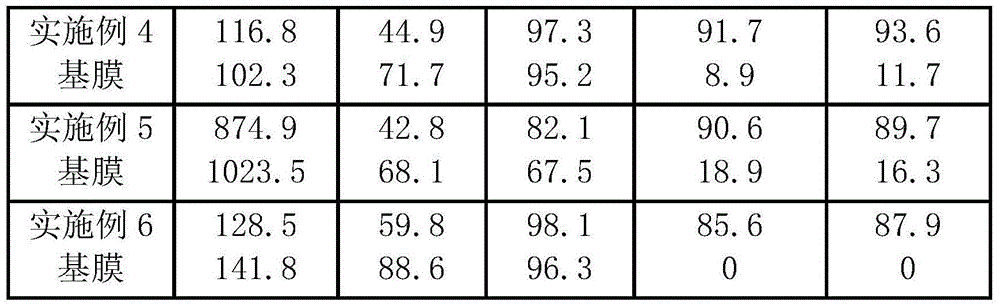

Embodiment 1

[0042] Select a flat ultrafiltration membrane made of polysulfone as the base membrane (see Table 1 for the main membrane parameters), soak it in a 5% polyethyleneimine deionized aqueous solution, stir it at a slow speed for 12 hours, take it out, and use Wash away the excess polyethyleneimine on the surface of the polysulfone ultrafiltration membrane with deionized water oscillation, dry it and immerse it in a copper acetate solution with a mass percentage of 5%, stir at a slow speed for 6 hours to carry out the coordination complexation reaction, take it out and use it The superfluous metal ions on the surface of the modified polysulfone ultrafiltration membrane were shaken and washed with ion water to obtain a polysulfone ultrafiltration membrane modified by hydrophilic antibacterial, and then soaked in 20% glycerin aqueous solution to preserve the pores for later use. The performance parameters of the prepared modified membrane and the base membrane are shown in Table 1.

Embodiment 2

[0044] Take the flat ultrafiltration membrane made of polyethersulfone as the base membrane (see Table 1 for the main membrane parameters), soak it in a mixture of 7% chitosan and 3% water-soluble chitosan for deionization In the aqueous solution, take it out after stirring at a slow speed for 24 hours, shake off the excess chitosan and chitosan molecules on the surface of the polysulfone ultrafiltration membrane with deionized water, and immerse it in a silver nitrate solution with a mass percentage of 10% after drying. Stir at a slow speed for 4 hours to carry out the coordination and complexation reaction. After taking it out, shake and wash the excess metal ions on the surface of the modified polyethersulfone ultrafiltration membrane with deionized water to obtain a hydrophilic antibacterial modified polyethersulfone ultrafiltration membrane. , and then soaked with 20% glycerin aqueous solution to preserve the pores for later use. The performance parameters of the prepared...

Embodiment 3

[0046] Select a flat ultrafiltration membrane made of sulfonated polysulfone / polyethersulfone as the base membrane (see Table 1 for the main membrane parameters), soak it in a deionized aqueous solution of polylysine with a mass percentage of 1% and stir slowly for 16 Take it out after 1 hour, shake off the excess polylysine molecules on the surface of the sulfonated polysulfone / polyethersulfone ultrafiltration membrane with deionized water, immerse in a zinc acetate solution with a mass percentage of 3% after drying, and stir at a slow speed for 12 After taking it out, shake and wash the excess metal ions on the surface of the sulfonated polysulfone / polyethersulfone ultrafiltration membrane with deionized water to obtain the hydrophilic and antibacterial modified sulfonated polysulfone / polyethersulfone ultrafiltration membrane. filter membrane, and then soaked with 20% glycerol aqueous solution to preserve the pores. The performance parameters of the prepared modified membran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com