Nano iron/oyster shell composite material, and preparation method and application thereof

A composite material, oyster shell technology, applied in chemical instruments and methods, other chemical processes, water/sewage treatment, etc., can solve the problems of increased stability and controllability of composite materials, easy loss, oxidation, etc. Solving problems, stable performance, and solving the effect of easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of nanometer iron / oyster shell composite material, concrete steps are:

[0028] 1) Pretreatment of oyster shells: rinse the oyster shells with tap water, pre-burn the oyster shells at 100-600 ℃ for 1 hour, keep the temperature for 1 hour, cool naturally, grind them into 65-mesh oyster shell powder, and store them in a desiccator for later use; the programmed temperature rise interval is 100 ℃;

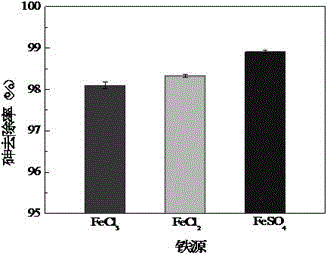

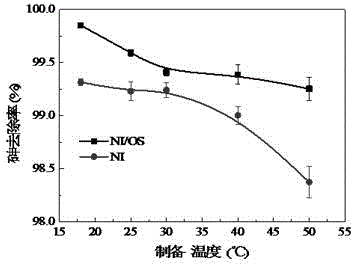

[0029] 2) In-situ synthesis of composite materials: 1 g of oyster shell powder and 30 mL (0.45 mol / L) of iron source solution in step 1) were added into a three-neck flask, and mixed with ultrasonic-assisted mechanical stirring at low speed for 30 min (stirring speed 500 r / L). min, ultrasonic power 100 W, mixing temperature 20 ℃), then add KBH dropwise under nitrogen protection 4 Solution (0.9 mol / L) 5 mL, ultrasonically assisted mechanical medium-speed stirring reaction for 15 min (stirring speed 1000 r / min, ultrasonic power 100 W, reaction temperature 2...

Embodiment 2

[0033] NaBH 4 and KBH 4 As reducing agent, 65 mesh oyster shell powder, FeSO 4 Be iron source, all the other parameters are identical with embodiment 1. Add the same amount of composite materials prepared by different reducing agents into the arsenic stock solution (pH: 7, arsenic concentration: 2 mg / L), set up three groups of parallel and blank samples for each condition, and use nitrogen to exhaust the upper layer of air, then use After the plastic wrap was sealed, put it into a constant temperature shaking box to react for 24 hours (rotational speed: 200 r / min, temperature: 20 ℃), the supernatant was taken to measure the arsenic concentration, and the composite materials prepared with different reducing agents were compared to the arsenic concentration in the solution. The removal effect is shown in Table 1. when in KBH 4 When used as a reducing agent, the removal effect of arsenic in the solution can reach 99.80%, and the effect is remarkable.

[0034] Table 1 Effect ...

Embodiment 3

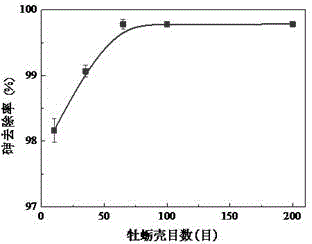

[0037] Choose 10, 35, 65, 100, 200 mesh oyster shell powder, FeSO 4 For Iron Source, KBH 4 Be reducing agent, all the other parameters are identical with embodiment 1. The same amount of composite materials prepared from oyster shell powder with different meshes was added to the arsenic stock solution (pH: 7, arsenic concentration: 2 mg / L). Three groups of parallel and blank samples were set up for each condition, and the upper layer of air was exhausted with nitrogen gas. , sealed with plastic wrap and placed in a constant temperature oscillation box to react for 24 h (rotational speed: 200 r / min, temperature: 20 ℃), the supernatant was taken to measure the arsenic concentration, and the composite materials prepared by oyster shell powder with different meshes were compared The removal effect of arsenic in the solution, such as figure 2 shown. from figure 2 It can be seen from the figure that when the oyster shell powder mesh is lower than 100 mesh, the removal rate of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com