High-firmness honeycomb ceramic carrier and preparation method thereof

A honeycomb ceramic carrier, firmness technology, applied in catalyst carriers, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as unfavorable industrialization, peeling, and easy cracking of the coating, etc. Achieve good penetration performance and wetting performance, improve firmness and good dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

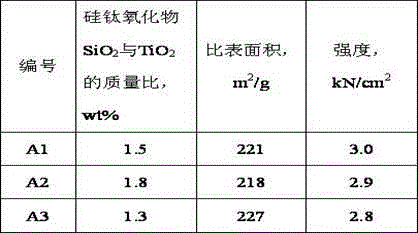

[0037] Cordierite acid treatment: add 5% hydrochloric acid solution to the lining to completely immerse the cordierite, seal the autoclave and place it in an oven at 250°C for 2 hours of hydrothermal treatment. After the hydrothermal treatment, the cordierite carrier was washed with distilled water until the washing liquid was neutral, and the distilled water on the surface was blown off with an air compressor, dried at 120°C for 8 hours, and calcined at 550°C for 3 hours to obtain a silicon-titanium oxide content of 2.8wt%. The properties of the product A1 are shown in Table 1.

[0038] Aluminum sol preparation: 20 grams of pseudoboehmite was added to 150 mL of deionized water, and 7 grams of concentrated nitric acid was added dropwise while stirring. After stirring for a certain period of time, heat to 80°C, add nitric acid dropwise until completely peptized, control the pH value of the solution at 2~5, and age for 24 hours to obtain a transparent aluminum sol with a content...

Embodiment 2

[0043] Cordierite acid treatment: Same as Example 1, except that 15% nitric acid solution was used instead and hydrothermally treated at 100°C for 3 hours to obtain a product A2 with a silicon-titanium oxide content of 0.5 wt%. The properties are shown in Table 1.

[0044] Aluminum sol is commercially available (solid content is 15%, pH is 3-4).

[0045] Composite coating slurry preparation: Add 54 grams of nano-titanium dioxide (50-100nm), 32 grams of fumed silica (10-80nm), and 17.2 grams of nano-cerium oxide into 280ml of carbonic acid solution (0.2mol / L), and stir evenly Finally, add 43 grams of aluminum sol to it, stir and mix for 90 minutes until uniform, add 4.3 grams of alkylphenol polyoxyethylene ether (molecular formula is RC 6 h 4 O(CH 2 CH 2 O) n H, where R is C 9 ~C 12 , n is 9~12), and then stir and mix for 30 minutes to obtain a uniform coating slurry.

[0046] Coating loading: Immerse A2 in the above-mentioned aluminum sol for 10 minutes, take it out, bl...

Embodiment 3

[0049] Cordierite acid treatment: Same as Example 1, except that 10% sulfuric acid solution was used instead and hydrothermally treated at 175°C for 1.5 hours to obtain a product A3 with a silicon-titanium oxide content of 1.2 wt%. The properties are shown in Table 1.

[0050] Aluminum sol preparation: same as embodiment 1.

[0051] Composite coating slurry preparation: Add 25 grams of nano-titanium dioxide (100-150nm), 5 grams of fumed silica (10-80nm), and 9.2 grams of nano-zirconia into 210ml of carbonic acid solution (0.3mol / L), and stir evenly Finally, 45 grams of aluminum sol was added thereto, and 6.1 grams of secondary octanol polyoxyethylene ether (molecular formula C 8 h 17 (CH 2 CH 2 O) n H, wherein n is 1 ~ 6), and then shear and disperse for 5 minutes to obtain a coating slurry.

[0052] Alumina coating loading: Immerse A3 in the aluminum sol prepared above for 8 minutes, take it out, blow off the residual liquid, dry at 110°C for 10 hours, and bake at 500°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com