Deep desulfurization method of refinery C4

A technology for carbon 4 and deep desulfurization in refineries, applied in chemical instruments and methods, purification/separation of hydrocarbons and hydrocarbons, etc., can solve the problems of increased desulfurization cost, high catalyst cost, unsatisfactory desulfurization effect, etc. Simple and effective process, avoid secondary pollutants, excellent desulfurization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

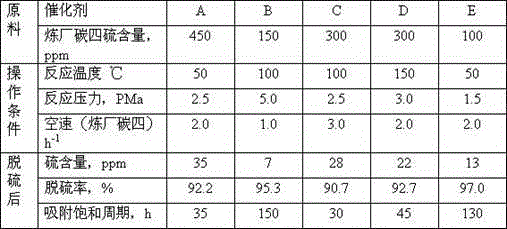

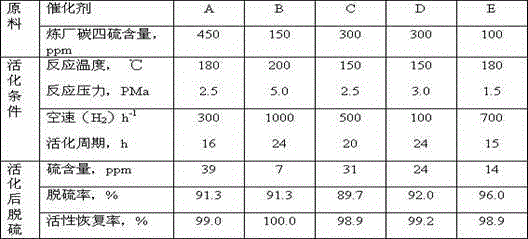

Examples

Embodiment 1

[0018] Take alumina (specific surface area 330 m 2 / g, pore volume 0.75 cm 3 / g) 85.0g, add 73.0g distilled water and 10.5ml concentrated nitric acid, mix well, and make a binder. Take 145.5g of HZSM-5 (the ratio of silicon to aluminum is 50), knead 4.0g of Tianqing powder and the above binder, extrude into strips, dry the wet strips at 120°C for 4 hours, and bake them at 550°C for 5 hours to produce Adsorbent. Dissolve 47.5g of ammonium metatungstate and 51.2g of nickel nitrate in distilled water to make a 200ml solution, add the above adsorbent into the impregnation solution, soak for 2 hours, then filter, dry at 110°C for 4 hours, and roast at 550°C 3 hours, then carry out secondary impregnation, take 32.2g zirconium nitrate pentahydrate, 23.3g zinc nitrate hexahydrate, dissolve with distilled water, make 200ml solution, add the above-mentioned adsorbent in the impregnation solution, impregnate for 2 hours, then filter, in Drying at 110°C for 4 hours, and calcining at 55...

Embodiment 2

[0023] Take alumina (specific surface area 310 m 2 / g, pore volume 0.96 cm 3 / g) 85.0g, add 73.0g distilled water and 10.5ml concentrated nitric acid, mix well, and make a binder. Take 145.5g of HZSM-5 (the ratio of silicon to aluminum is 25), knead 3.0g of Tianqing powder and the above binder, extrude into strips, dry the wet strips at 120°C for 4 hours, and bake them at 550°C for 5 hours to produce carrier. Dissolve 31.6g of ammonium metatungstate and 25.6g of nickel nitrate in distilled water to make a 200ml solution, add the above carrier into the impregnation solution, impregnate for 2 hours, then filter, dry at 110°C for 4 hours, and roast at 550°C for 3 hours. hours, then carry out secondary impregnation, take 27.6g of zinc nitrate hexahydrate and 14.4g of cerium nitrate hexahydrate and dissolve them in distilled water to make a 200ml solution, add the above carrier into the impregnation solution, impregnate for 2 hours, then filter, Dry for 4 hours, and bake at 550°...

Embodiment 3

[0026] Take alumina (specific surface area 330 m 2 / g, pore volume 0.75 cm 3 / g) 85.0g, add 73.0g distilled water and 10.5ml concentrated nitric acid, mix well, and make a binder. Take 145.5g of HZSM-5 (the ratio of silicon to aluminum is 80), knead 3.0g of Tianqing powder and the above binder, extrude into strips, dry the wet strips at 120°C for 4 hours, and bake them at 550°C for 5 hours to produce carrier. Dissolve 62.4g of ammonium molybdate and 34.1g of nickel nitrate in distilled water to make a 200ml solution, add the above carrier into the impregnation solution, impregnate for 2 hours, then filter, dry at 110°C for 4 hours, and roast at 550°C for 3 hours , and then carry out secondary impregnation, take 15.6g of copper nitrate trihydrate and 20.5g of cerium nitrate hexahydrate dissolved in distilled water to make a 200ml solution, add the above carrier into the impregnation solution, impregnate for 2 hours, then filter and dry at 110°C 4 hours, then calcined at 550°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com