Bacillus licheniformis with biomass hydrolase activity and application thereof

A technology of bacillus licheniformis and hydrolase, applied in the direction of microorganism-based methods, applications, microorganisms, etc., can solve the problems of incomplete transformation of humus, long fermentation time, etc., and achieve good economic and social benefits and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

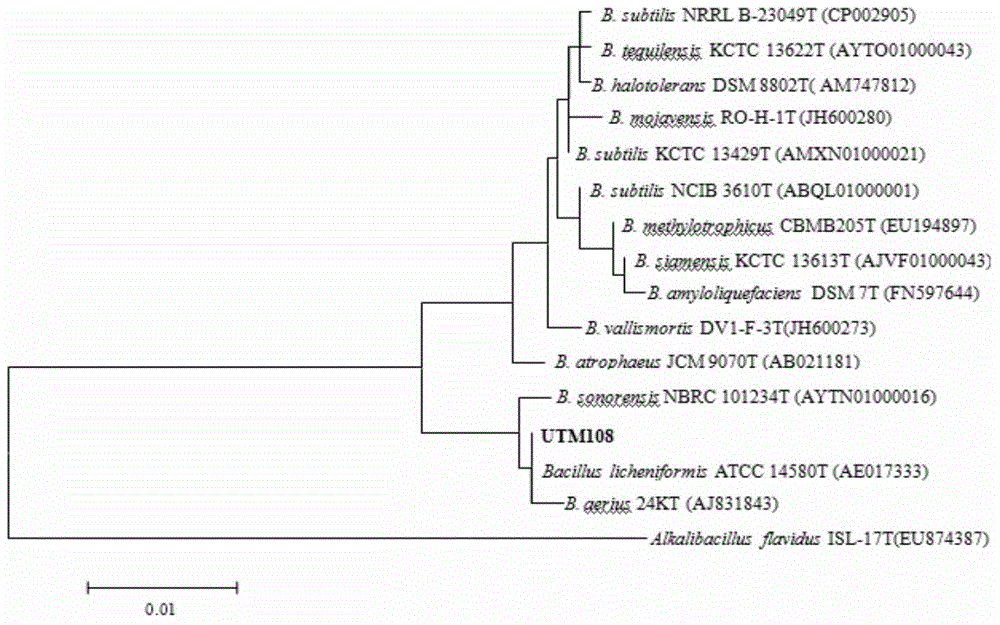

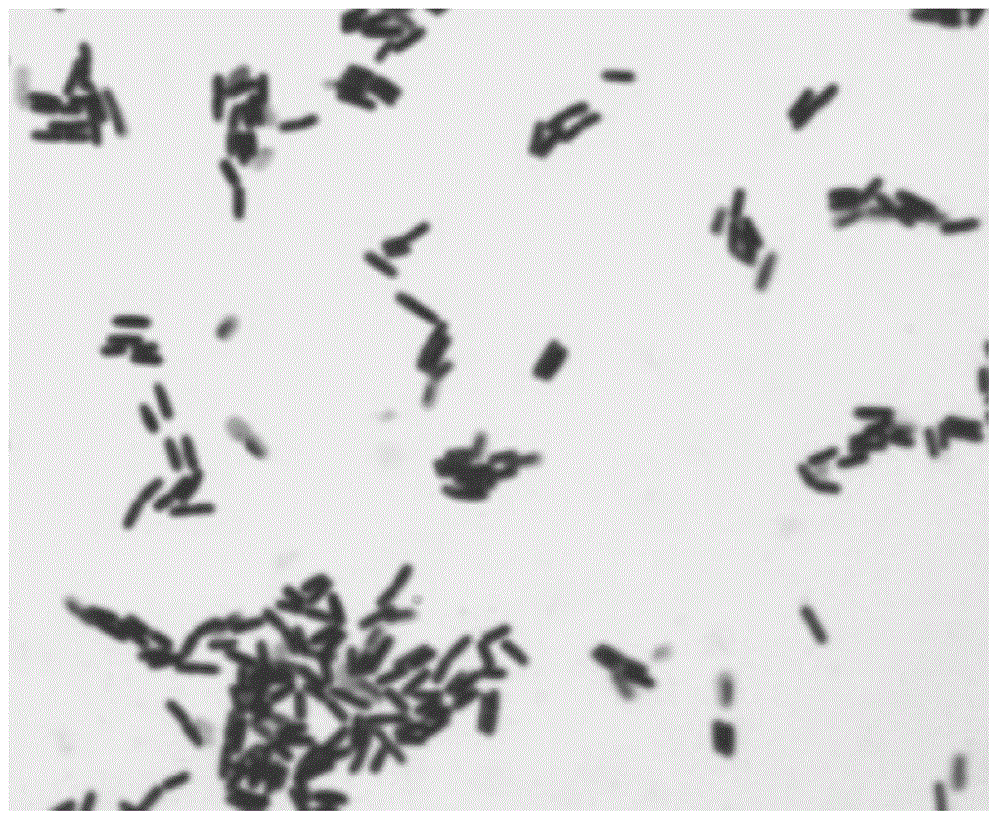

[0035] Example 1 Isolation and Identification of Bacillus licheniformis UTM108

[0036] Take about 1g of bottom mud sample of Tengchong Hot Spring in Yunnan Province and place it in a 250ml triangular flask filled with several small glass beads, which contains 100ml of sterile water. Shake on a constant temperature shaker at 40°C for 1 hour and then let stand for 30 minutes. Aseptically draw 1ml of the supernatant and transfer to 100ml of sterilized enrichment medium ((NH 4 ) 2 SO 4 0.06%, K 2 HPO 4 0.2%, MgSO 4 ·7H 2 O 0.04%, K 2 SO 4 0.02%, NaCl 0.01%, CaCl 2 2H 2O 0.03%, hemicellulose 1.5%, agar 1.5%, pH 6.5). Shake enrichment and acclimation culture on a constant temperature shaker at 40°C for 3 days, with a rotation speed of 160 rpm. Take 1ml of the bacterial suspension after 3 days of cultivation, add it to a test tube containing 9ml of sterile water, and make 10ml by gradient dilution method. -1 、10 -2 、10 -3 、10 -4 、10 -5 、10 -6 、10 -7 the dilution. ...

Embodiment 2

[0038] Example 2 Detection of xylan deacetylase activity of bacterial strain UTM108 and its gene sequence

[0039] Take 100ml of UTM108 bacteria liquid (5g of beef extract, 5g of yeast extract, 10g of peptone, 5g of sodium chloride, 5g of hemicellulose, 15g of soluble starch, 1000ml of distilled water, pH7.2, cultured at 40°C for 2 days) and centrifuge (6000 rpm / minutes to 10 minutes) to collect the bacteria. The cells were placed in phosphate buffer (pH 7.4), and the cells were disrupted 20 times in a row using an ultrasonic disruptor (600W) with a working time of 5 seconds and an interval of 5 seconds. Centrifuge (7500 rpm, 10 minutes) to obtain the supernatant, that is, to obtain the crude enzyme solution.

[0040] Xylan deacetylase activity was measured with p-nitrophenol acetate as a substrate, and the reaction mixture contained 500 μl p-nitrophenol acetate (5% suspended in 50 mmol / L sodium phosphate buffer, pH 7.0), 450 μl 50 mmol / L L sodium phosphate buffer (pH 7.0) ...

Embodiment 3

[0042] Example 3 Detection of strain UTM108α-L-arabinofuranosidase activity and related gene sequences

[0043] Inoculate the activated UTM108 strain on the LB slant (tryptone 10g, yeast extract 5g, sodium chloride 10g, agar 15g, distilled water 1000ml, pH 7.2) in xylan-containing medium (peptone 4g, oat xylan Sugar 5g, glucose 4g, sodium chloride 5g, distilled water 1000ml, pH7.2), 40 ℃ shaking (160 rpm) for two days, centrifuged (6000 rpm, 10 minutes) to collect the bacteria. The cells were placed in phosphate buffer (pH 7.4), and the cells were disrupted 20 times in a row with an ultrasonic disruptor (power 600W) for 5 seconds with an interval of 5 seconds. Centrifuge (7500 rpm, 10 minutes) to obtain the supernatant to obtain the crude enzyme solution. Arabinosidase activity is determined by the release of p-nitrophenol (pNP) from the substrate p-nitrophenyl-arabinofuranoside (pNPAF). Take 10μl of the enzyme solution to be tested and add it to 0.18ml 0.1mmol / L pH 5.8 buff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com