Chromium-free passivation treatment agent used before coating of cast aluminum alloy workpiece

A chromium-free passivation, cast aluminum alloy technology, applied in the direction of metal material coating technology, can solve the problems of inability to achieve traditional passivation, can not meet the requirements, achieve short processing time, improve corrosion resistance, and simple processing technology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

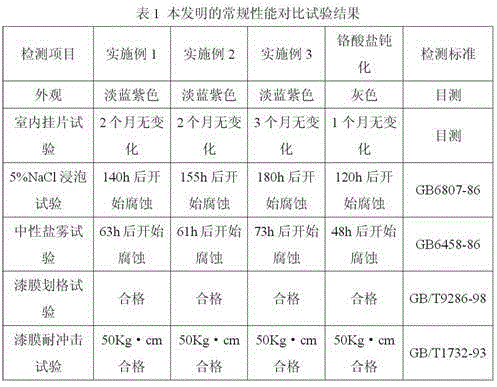

Examples

Embodiment 1

[0012] A chromium-free passivation treatment agent for cast aluminum alloy workpieces before coating, made of the following raw materials in weight percentages: 5% potassium persulfate, 5% sorbitol, 0.5% ammonium metavanadate, diisobutylnaphthalenesulfonate Sodium phosphate 0.5%, potassium zirconium carbonate 0.1%, ferrocenecarboxylic acid 0.08%, polyoxyethylene lauryl ether 0.05%, sodium pyrrolidone hydroxy acid 0.05%, and the balance is water.

[0013] The preparation method of the above-mentioned chromium-free passivation treatment agent for cast aluminum alloy workpieces before coating comprises the following steps: potassium persulfate and sorbitol are added in water to be miscible in a reaction kettle, and then ammonium metavanadate and diiso Sodium butylnaphthalene sulfonate, stirred and dissolved, and the solution was left to stand for 2 hours; followed by adding potassium zirconium carbonate, ferrocene formic acid, polyoxyethylene lauryl ether, sodium pyrrolidone hydro...

Embodiment 2

[0015] A chrome-free passivation treatment agent for cast aluminum alloy workpieces before coating, which is made of the following raw materials in weight percentage: 10% potassium persulfate, 1% sorbitol, 1.5% ammonium metavanadate, diisobutylnaphthalenesulfonate 0.1% sodium bicarbonate, 0.5% potassium zirconium carbonate, 0.05% ferrocenecarboxylic acid, 0.08% polyoxyethylene lauryl ether, 0.01% sodium pyrrolidone hydroxy acid, and the balance is water.

[0016] The preparation method of the chromium-free passivation treatment agent before coating the cast aluminum alloy workpiece is the same as that in Example 1.

Embodiment 3

[0018] A chromium-free passivation treatment agent for cast aluminum alloy workpieces before coating, made of the following raw materials in weight percentages: 7.5% potassium persulfate, 3% sorbitol, 1% ammonium metavanadate, diisobutylnaphthalenesulfonate Sodium phosphate 0.3%, potassium zirconium carbonate 0.3%, ferrocenecarboxylic acid 0.065%, polyoxyethylene lauryl ether 0.065%, sodium pyrrolidone hydroxy acid 0.03%, and the balance is water.

[0019] The preparation method of the chromium-free passivation treatment agent before coating the cast aluminum alloy workpiece is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com