Film having protein adsorption resistance and preparation method thereof

An anti-protein adsorption and thin film technology, applied in electrolytic organic production, electrolytic organic material coating, electrolytic components, etc., to achieve the effects of reducing non-specific protein adsorption, good permeability, and strong manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

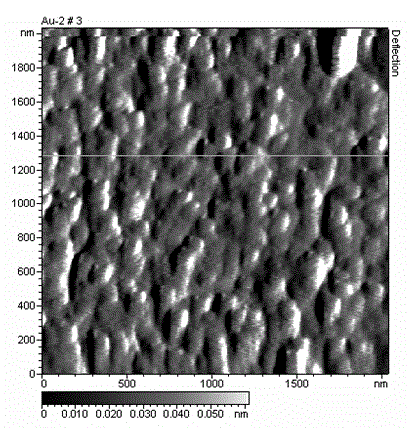

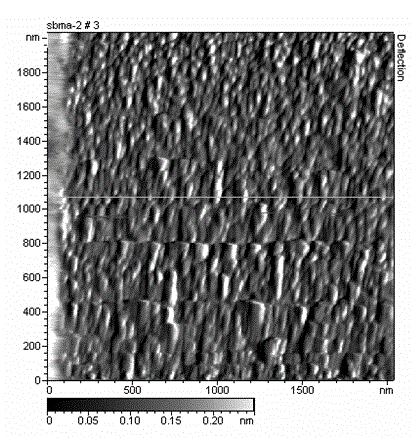

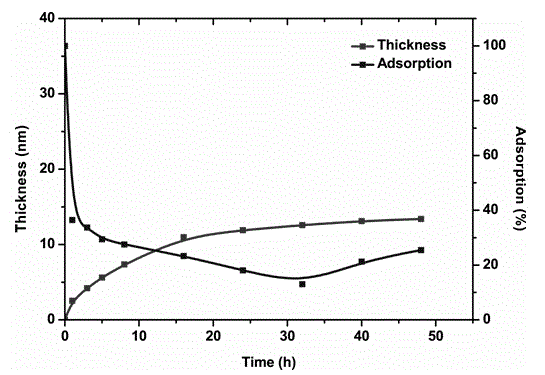

Image

Examples

Embodiment 1

[0027] The film of this embodiment is prepared by the following method:

[0028] (1) Bromination of the enzyme electrode: first place the enzyme electrode in 0.1mol / L, pH=8 phosphate buffered saline (PBS), dissolve 10ul BIBB in 0.5ml dichloromethane, then add the aforementioned PBS dropwise , stirred at 800 rpm for 1 hour; the brominated enzyme electrode was taken out, washed with deionized water, and dried at room temperature;

[0029] (2) Preparation of polymer monomer solution: take 8 g of sulfobetaine methacrylate (SBMA) monomer, dissolve it in 20 ml of PBS with a pH of 7.4 at 0.1 mol / L, and add the catalyst at a final concentration of 5 mmol / l Divalent copper ion solution, add ligand bipyridine (BPY) at a final concentration of 5 mmol / l, mix thoroughly to form a clear solution;

[0030] (3) Electrically induced atom transfer radical polymerization: the brominated enzyme electrode was used as the working electrode, the silver / silver chloride electrode was used as the refe...

Embodiment 2

[0033] The film of this embodiment is prepared by the following method:

[0034] (1) Bromination of the enzyme electrode: first place the enzyme electrode in 0.1mol / L, pH=8 PBS, dissolve 10ul of dibromoisobutyryl bromide (BIBB) in 0.5ml of dichloromethane, and then add it dropwise In the aforementioned PBS, stir at 800 rpm for 1 hour; take out the brominated enzyme electrode, wash it with deionized water, and dry it at room temperature;

[0035] (2) Preparation of polymer monomer solution: Take 8g of SBMA monomer, dissolve it in 20ml of PBS with a pH of 7.4 at 0.1mol / L, add the catalyst divalent copper ion solution at a final concentration of 5mmol / L, and add a solution of divalent copper ions at a final concentration of 5mmol / L Add the ligand tris(2-pyridylmethyl)amine (TPMA) and mix well to form a clear solution;

[0036] (3) Electrically induced atom transfer radical polymerization: the brominated enzyme electrode was used as the working electrode, the silver / silver chlor...

Embodiment 3

[0039] The film of this embodiment is prepared by the following method:

[0040] (1) Bromination of the enzyme electrode: first place the enzyme electrode in 0.2mol / L, pH=8 PBS, dissolve 5ul BIBB in 1ml dichloromethane, add dropwise to the aforementioned PBS, at 800 rpm Stir for 1 hour; take out the brominated enzyme electrode, wash it with deionized water, and dry it at room temperature;

[0041] (2) Preparation of polymer monomer solution: take 1 g of SBMA monomer, dissolve it in 20 ml of PBS with a pH of 8 at 0.2 mol / L, add the catalyst divalent copper ion solution at a final concentration of 5 mmol / L, and add a solution of divalent copper ions at a final concentration of 10 mmol / L Add the ligand BPY and mix well to form a clear solution;

[0042] (3) Electrically induced atom transfer radical polymerization: the brominated enzyme electrode was used as the working electrode, the silver / silver chloride electrode was used as the reference electrode, the platinum wire electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com