Silicon-carbon nanocomposite film, preparation method and application thereof and lithium ion battery

A carbon nanocomposite, lithium-ion battery technology, applied in battery electrodes, nanotechnology, nanotechnology and other directions, can solve the problems of low reversible capacity of negative electrode materials, low silicon specific gravity, short cycle life, etc., to simplify the battery assembly process, cycle Longer life and stable cycle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention also provides a method for preparing a silicon-carbon nanocomposite film, the method comprising the following steps:

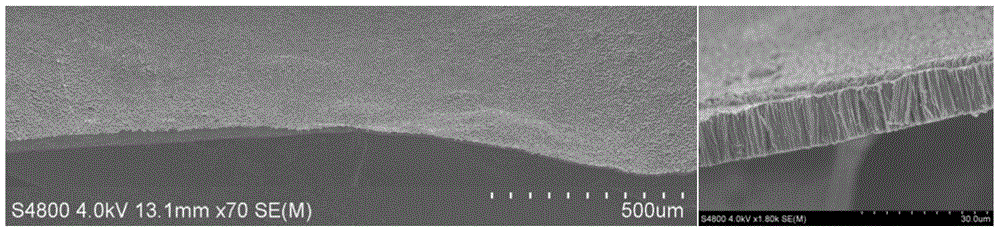

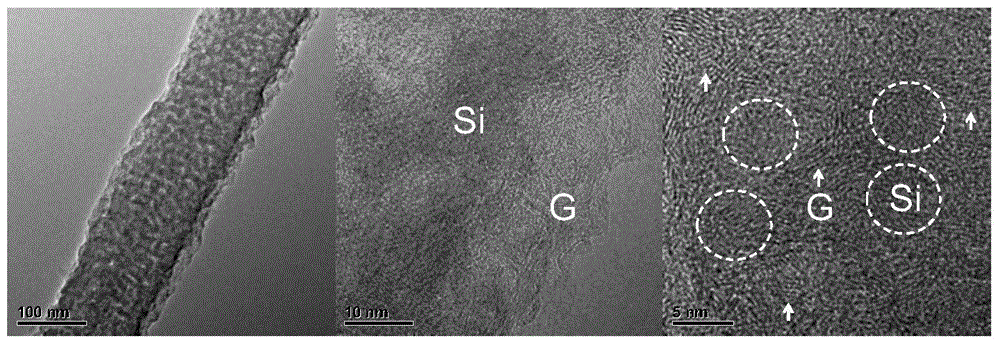

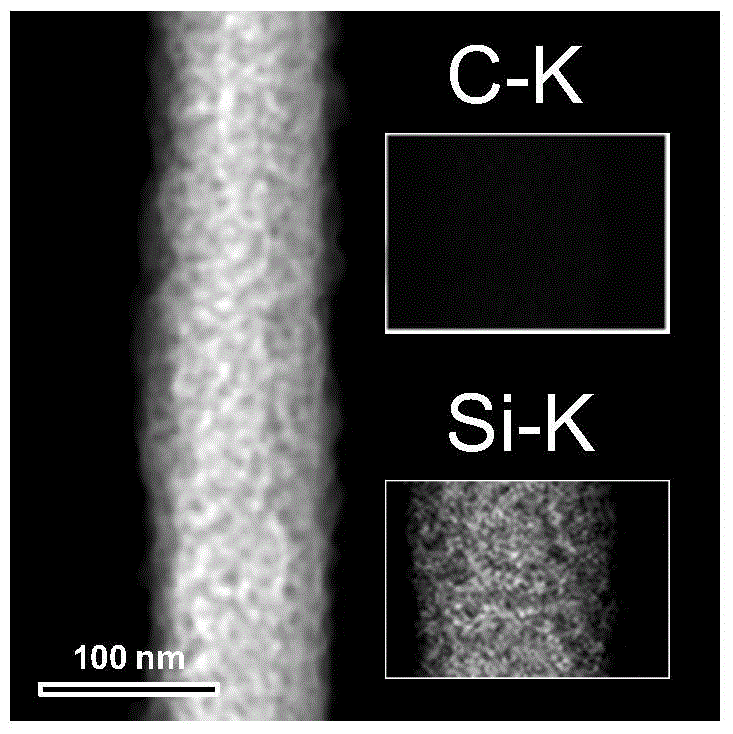

[0028] (1) Etching the silicon wafer with an etching solution to form a porous silicon nanowire array on the surface of the silicon wafer;

[0029] (2) Depositing carbon nanomaterials on the porous silicon nanowire arrays by chemical vapor deposition using hydrocarbons as carbon sources and inert gases and / or hydrogen as carrier gases to form silicon-carbon on silicon wafers Nanocomposite films;

[0030] (3) In an alkaline aqueous solution, the silicon-carbon nanocomposite film on the silicon wafer is peeled off.

[0031] According to the method of the present invention, wherein, in step (1), the silicon wafer may be a polycrystalline silicon wafer or a single crystal silicon wafer, preferably a single crystal silicon wafer, and more preferably a single crystal with a resistivity less than 5 mΩ·cm silicon wafer.

[0032] Accordi...

Embodiment 1

[0052] Take a single crystal silicon wafer with a resistivity lower than 5mΩ·cm, put it in a plastic cup, add an aqueous solution of 0.02M silver nitrate and 5M hydrofluoric acid, and keep it warm at 50°C for 20 minutes. A layer of porous silicon nanometers is formed on the surface of the silicon wafer. For the line array, take out the silicon chip and rinse it with water, then immerse it in concentrated nitric acid for half an hour, take it out, then immerse it in water for half an hour, take it out and dry it at 60°C. Then put it into the middle of the tube furnace, feed argon hydrogen gas mixture (2 / 1, v / v), the total flow rate is 300sccm, after the temperature is programmed to 1050°C, start to feed methane, the flow rate is 100sccm, keep the temperature for 5 minutes Cool down quickly. After cooling down to room temperature, take out the silicon wafer from the furnace, immerse it in 5% sodium hydroxide aqueous solution at 90°C, react for 1 hour, and peel off the silicon-ca...

Embodiment 2

[0055] Take a single crystal silicon wafer with a resistivity lower than 5mΩ·cm, put it in a plastic cup, add an aqueous solution of 0.02M silver nitrate and 5M hydrofluoric acid, and keep it warm at 50°C for 30 minutes. A layer of porous silicon nanometers is formed on the surface of the silicon wafer. For the line array, take out the silicon chip and rinse it with water, then immerse it in concentrated nitric acid for half an hour, take it out, then immerse it in water for half an hour, take it out and dry it at 60°C. Then put it into the middle of the tube furnace, feed argon hydrogen gas mixture (2 / 1, v / v), the total flow rate is 300sccm, after the temperature is programmed to 1050°C, start to feed methane, the flow rate is 400sccm, keep the temperature for 5 seconds Cool down quickly. After cooling down to room temperature, take out the silicon wafer from the furnace, immerse it in 5% sodium hydroxide aqueous solution at 90°C, react for 1 hour, and peel off the silicon-ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com