A combined collector for increasing iron and reducing silicon, and its preparation method and application

A combined collector and silicon reduction technology, applied in solid separation, flotation, etc., can solve the problems of low concentrate yield and high silicate content in concentrate, so as to improve production indicators, make up for performance defects, and excellent iron extraction Effect of silicon reduction characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

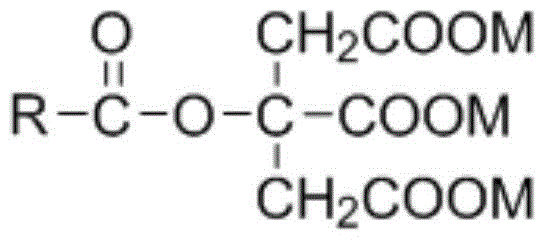

[0043] Embodiment 1: Preparation of A anionic tricarboxylic acid salts:

[0044] Weigh 40g (0.2mol) of saturated fatty acid-lauric acid, place in a 500ml four-necked reaction flask with a thermometer, a condenser, and mechanical stirring, then add 2.76g (0.02mol) of potassium carbonate, triethylbenzylamine salt 3.76g (0.02mol), stir well at room temperature, then control the temperature at 40°C, slowly add 42.35g (0.22mol) of p-toluenesulfonyl chloride with a dropping funnel, react at 40°C for 1 hour, then add 200ml of xylene, Then slowly add citric acid 57.6g (0.3mol) with dropping funnel, reflux reaction 12 hours, the solution is neutralized to pH value 8 with 30% sodium hydroxide, the solid that precipitates, wash with ethanol after suction filtration and obtain It is the product Sodium Lauroyl Citrate.

Embodiment 2

[0045] Embodiment 2: the preparation of A anionic tricarboxylic acid salts:

[0046]Weigh 56.4g (0.2mol) of unsaturated fatty acid-oleic acid, place in a 500ml four-necked reaction flask with a thermometer, a condenser, and mechanical stirring, then add 2.76g (0.02mol) of potassium carbonate, triethylbenzyl 3.76g (0.02mol) of amine salt, stir well at room temperature, then control the temperature at 40°C, slowly add 42.35g (0.22mol) of p-toluenesulfonyl chloride with a dropping funnel, react at 40°C for 1 hour, add 200ml di Toluene, then slowly add citric acid 57.6g (0.3mol) with a dropping funnel, reflux for 10 hours, neutralize the solution with 30% sodium hydroxide to a pH value of 8, and wash the precipitated solid with ethanol after suction filtration What is obtained is the product sodium oleoyl citrate.

Embodiment 3

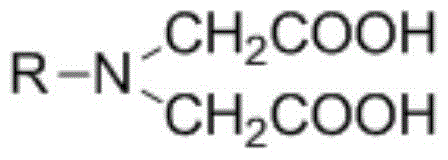

[0047] Embodiment 3: Preparation of B nitrogen-containing zwitterionic functional group-N-alkylaminodiacetic acids

[0048] Add 48g (0.5mol) of monochloroacetic acid into a 500ml four-necked reaction flask with mechanical stirring, condenser and thermometer, dissolve in 150ml of ethanol and 50ml of water, add 20g (0.5mol) of sodium hydroxide, and stir the reaction After adding phenolphthalein for 1 hour, the color becomes red, then 179.3 g (1.1 mol) of dodecylamine is added through a dropping funnel, and the reaction is carried out under reflux for 10 hours until the color of phenolphthalein disappears. Then use concentrated hydrochloric acid to adjust the pH value to 3-4, and a white precipitate is precipitated, and filtered to obtain the product N-dodecylaminodiacetic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com