A cavity length adjustable optical fiber f-p strain gauge based on mems technology and its forming method

A technology of strain gauge and optical fiber, which is applied in the field of high-precision optical fiber sensing and measurement, can solve the problems of improving the optical reflectivity of the reflective surface, low interference precision, and fluctuation of light source power, so as to improve strain resolution and measurement accuracy, and avoid interference Effects of spectral degradation and wide operating temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

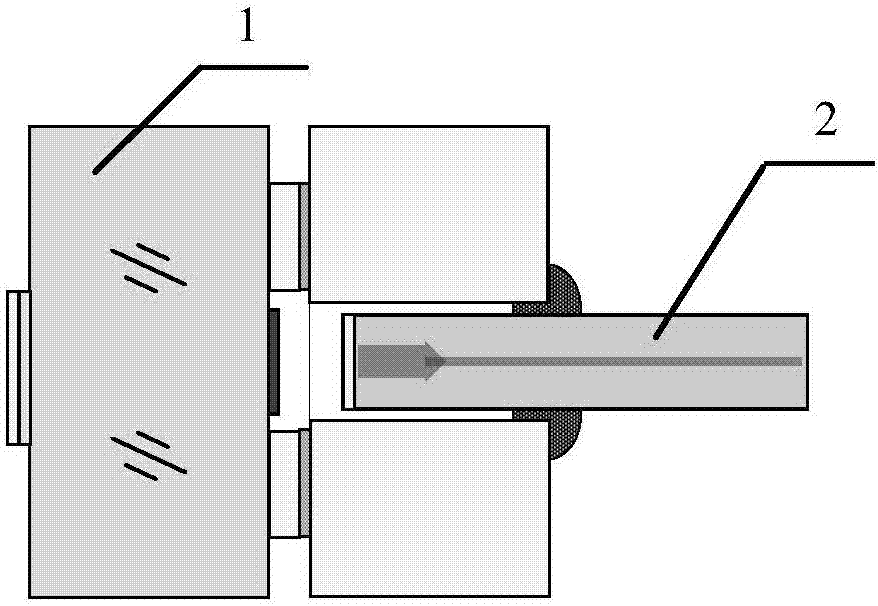

[0052] A kind of cavity length adjustable optical fiber F-P strain gauge based on MEMS technology, the structural diagram of the optical fiber F-P strain gauge is as follows figure 1 As shown, it mainly includes F-P strain sensitive MEMS chip 1 and collimated beam expanding fiber 2;

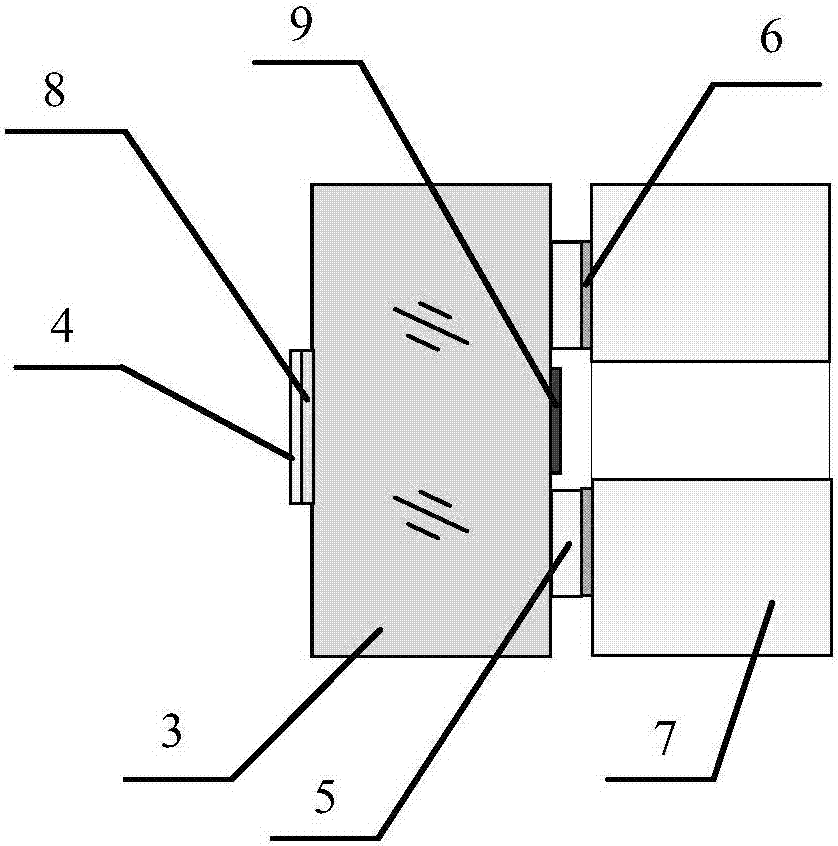

[0053] Wherein, the structure diagram of F-P strain-sensitive MEMS chip 1 is shown in Figure 2, and described F-P strain-sensitive MEMS chip 1 is made up of SOI silicon sheet and glass sheet 3;

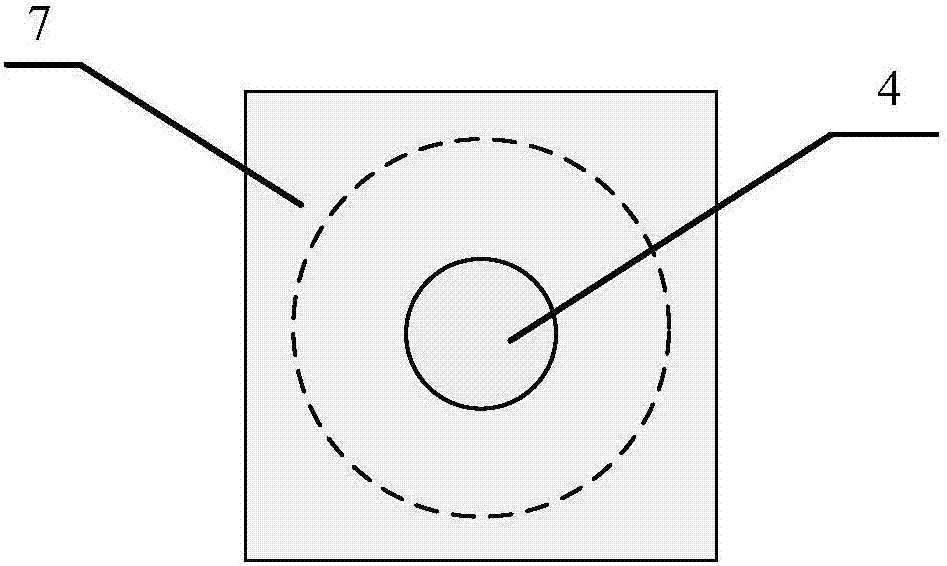

[0054] The SOI silicon wafer includes a top layer of silicon 5, an intermediate oxide layer 6, and a bottom layer of silicon 7; wherein, the top layer of silicon 5 is processed by patterned etching to become a "ring" strain beam, and the etching depth of the "ring" is as deep as that of the top layer of silicon 5 thickness; the middle oxide layer 6 and the bottom layer of silicon 7 are provided with round holes in the axial direction, and the radius of the round holes is greater than the outer diameter o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com