Nickel-cobalt sulpho-spinel for super capacitor and preparation method of nickel-cobalt sulpho-spinel

A cobalt thiospinel, supercapacitor technology, applied in the field of materials, can solve the problems of limited electrochemical performance, poor high current charge and discharge rate characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Synthesize about 0.4g of NiCo 2 S 4 The precursors of the three elements, nickel acetate, cobalt acetate and penicillamine, need to be weighed separately, while controlling the stoichiometric ratio Co:Ni:S=1:2:5. Place the weighed nickel acetate, cobalt acetate and penicillamine in the hydrothermal reaction kettle, and add 25mL deionized water to the hydrothermal reaction kettle, then add acetic acid to adjust the pH value in the hydrothermal reaction kettle to 5.5, stir After 30 minutes, the components were mixed uniformly to obtain the first mixture. Then put the hydrothermal reaction kettle in the electric furnace and react at 130°C for 45h to obtain the primary product. The initial product was collected by centrifugation, washed with deionized water and absolute ethanol several times, then dried in a vacuum oven at 50°C for 12 hours, and finally sintered at 250°C for 3 hours in a nitrogen atmosphere.

[0038] The preparation method of the supercapacitor: the prep...

Embodiment 2

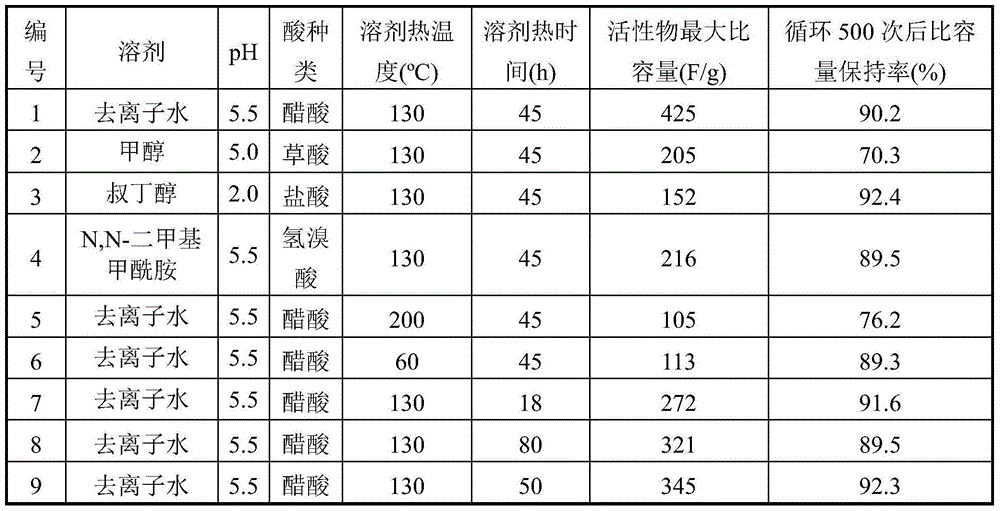

[0045] According to the steps described in Example 1, nickel acetate and cobalt acetate are used as the nickel source and the sulfur source, and penicillamine is the sulfur source. The chemical element stoichiometric ratio of Ni, Co, and S is 1:2:5, and the solvent type, pH value (type of inorganic acid), solvothermal temperature and solvothermal time, under the premise that other conditions remain unchanged, the obtained supercapacitor electrode performance is shown in Table 2 below.

[0046] Table 2 Determination results under different solvents, pH value, solvothermal temperature and solvothermal time

[0047]

Embodiment 3

[0049] According to the steps and components described in Example 1, the drying / calcination mode, temperature and time of the hydrothermal product were changed respectively, and under the premise that other conditions remained unchanged, the performance of the obtained supercapacitor electrode was tested, and the test results were as follows Table 3 shows.

[0050] Table 3 Determination results under different drying and calcination conditions

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com