Mesoporous nanotube material of inorganic salt, preparation method of mesoporous nanotube material by employing gradient pyrolysis and electrostatic spinning, and application of mesoporous nanotube material

A technology of inorganic salts and nanotubes, applied in the manufacture of hybrid/electric double layer capacitors, circuits, electrical components, etc., can solve problems such as limiting development and application, and achieve the effects of shortening the transmission path, improving electrochemical performance, and effective self-expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

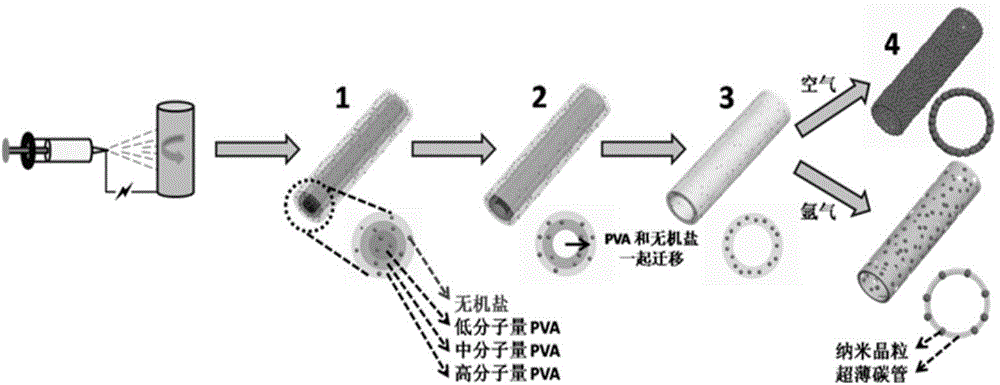

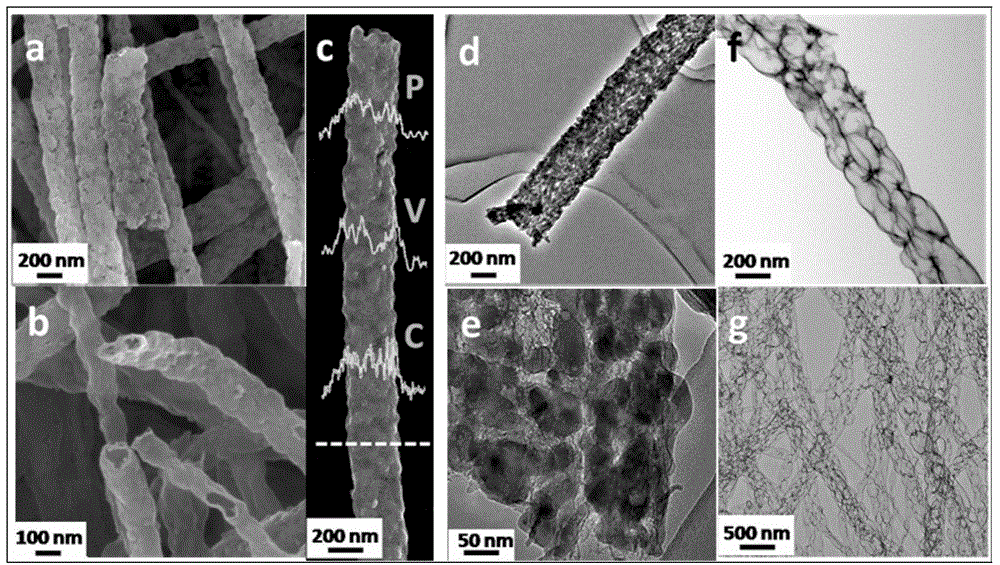

Method used

Image

Examples

Embodiment 1

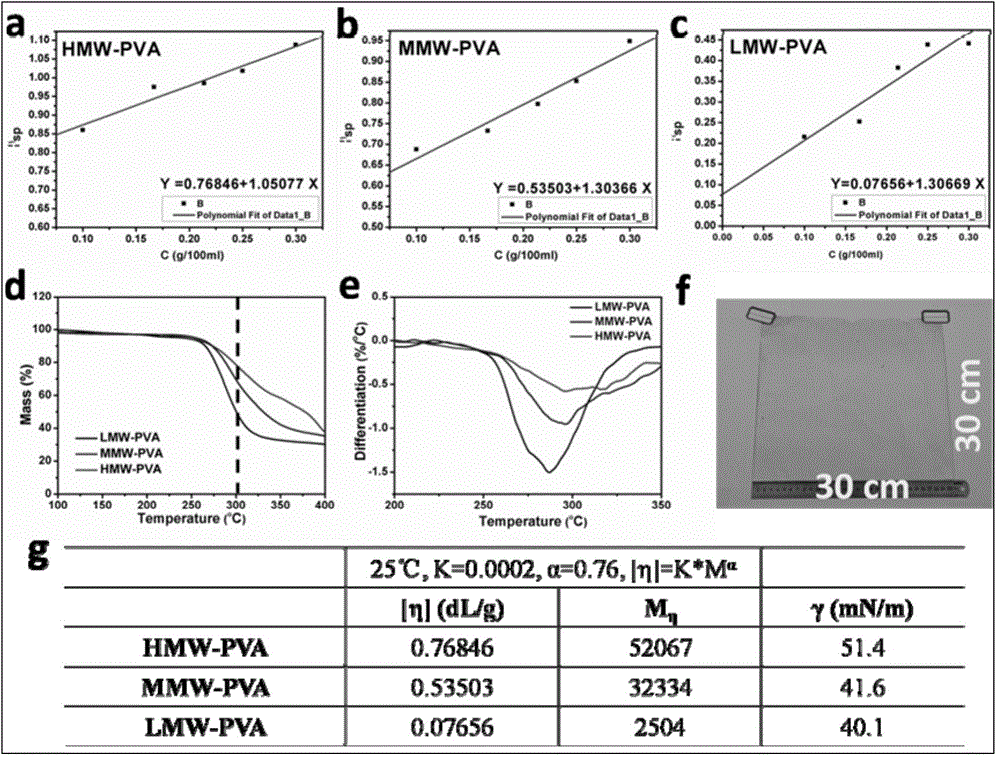

[0055] 1) Weigh 0.189g lithium hydroxide monohydrate, 0.345g ammonium metavanadate, 0.5175g ammonium dihydrogen phosphate, 0.40g oxalic acid dihydrate according to the stoichiometric ratio, add 20mL deionized water, and stir magnetically at room temperature to make it All dissolved to form a uniform and transparent solution;

[0056] 2) Weigh 1g of low-molecular-weight PVA, 0.70g of medium-molecular-weight PVA and 0.35g of high-molecular-weight PVA into the homogeneous transparent solution obtained in step 1), put it in a constant temperature water bath at 80°C, and stir it magnetically for 12 hours to make it dissolve;

[0057] 3) Take out the solution in step 2), and let it stand at room temperature for 2 hours to form a uniform, transparent, yellow precursor solution with a certain viscosity;

[0058] 4) Add the precursor obtained in step 3) into the syringe, perform electrospinning under the conditions of positive high voltage 17kV and negative high voltage -2kV, and rece...

Embodiment 2

[0068] 1) Weigh 0.345g of ammonium metavanadate and 0.5399g of sodium dihydrogen phosphate according to the stoichiometric ratio, add 20mL of deionized water, and magnetically stir at room temperature to dissolve them all, forming a uniform and transparent solution;

[0069] 2) Weigh 1g of low-molecular-weight PVA, 0.70g of medium-molecular-weight PVA and 0.35g of high-molecular-weight PVA into the homogeneous transparent solution obtained in step 1), put it in a constant temperature water bath at 80°C, and stir it magnetically for 12 hours to make it dissolve;

[0070] 3) Take out the solution in step 2), and let it stand at room temperature for 2 hours to form a uniform, transparent, yellow precursor solution with a certain viscosity;

[0071] 4) Add the sol precursor solution obtained in step 3) into the syringe, perform electrospinning under the conditions of positive high voltage 17kV and negative high voltage -2kV, and receive nanofibers with aluminum foil;

[0072] 5) ...

Embodiment 3

[0075] 1) Weigh 0.255g of sodium nitrate, 0.315g of manganese acetate tetrahydrate, 1.212g of ferric nitrate nonahydrate into 20mL of deionized water according to the stoichiometric ratio, and stir magnetically at room temperature to dissolve them all, forming a uniform and transparent solution.

[0076] 2) Weigh 1g of low-molecular-weight PVA, 0.70g of medium-molecular-weight PVA and 0.35g of high-molecular-weight PVA into the homogeneous transparent solution obtained in step 1), put it in a constant temperature water bath at 80°C, and stir it magnetically for 12 hours to make it dissolve.

[0077] 3) Take out the solution in step 2), and let it stand at room temperature for 2 hours to form a uniform, transparent, yellow precursor solution with a certain viscosity.

[0078] 4) Add the sol precursor solution obtained in step 3) into the syringe, perform electrospinning under the conditions of positive high voltage 17kV and negative high voltage -2kV, and receive nanofibers wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com