A lithium-sulfur battery positive electrode material, lithium-sulfur battery and preparation method thereof

A cathode material, lithium-sulfur battery technology, applied in battery electrodes, lithium batteries, battery pack components, etc., can solve the problems of inhibiting the ionic conductivity of lithium-sulfur batteries, and the inhibition is not effective enough, so as to inhibit the shuttle effect and avoid direct Contact, the effect of increasing the diffusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

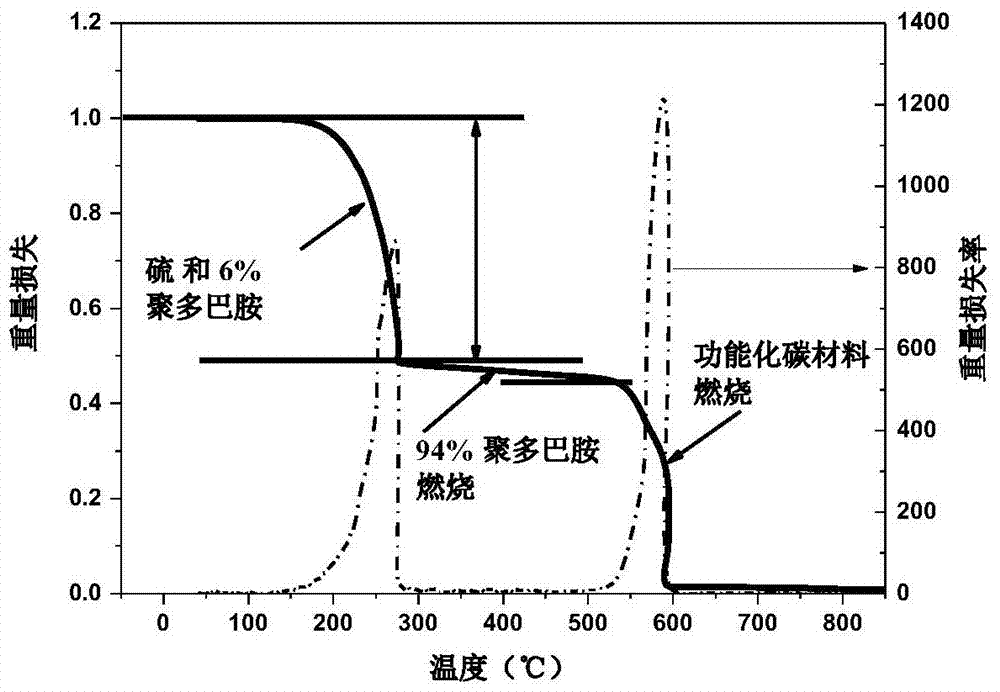

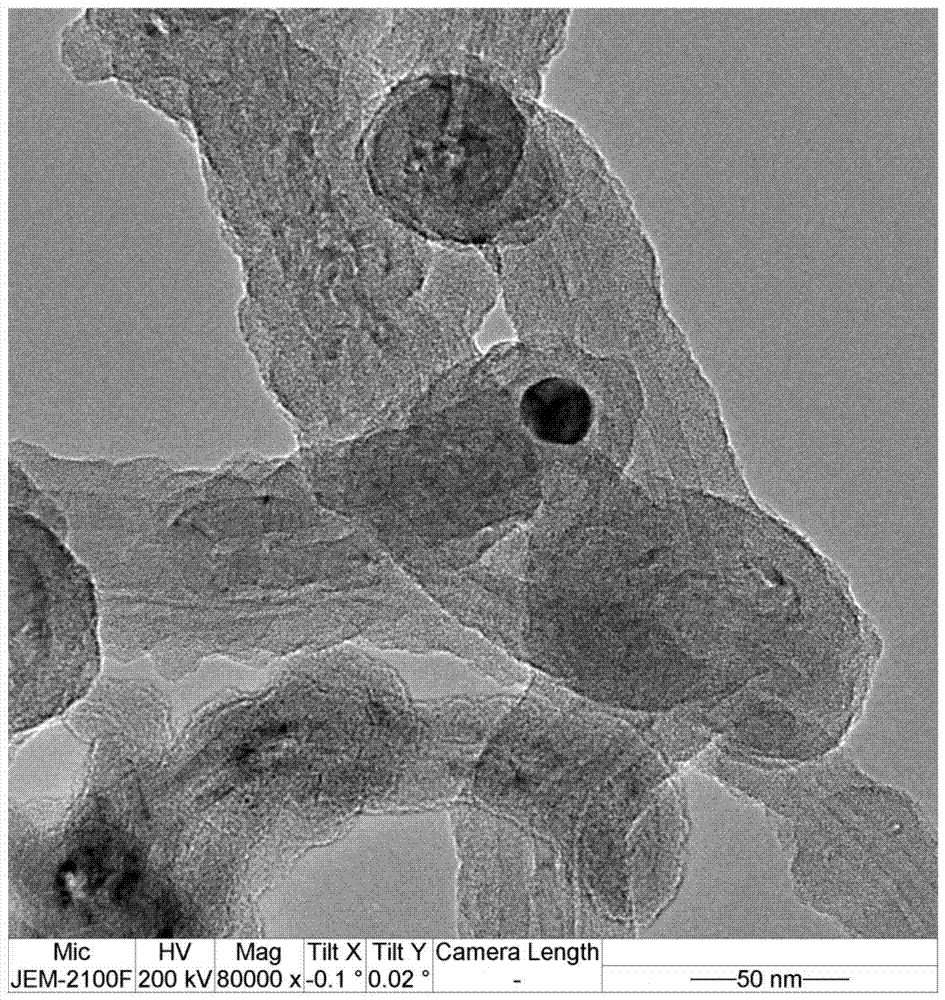

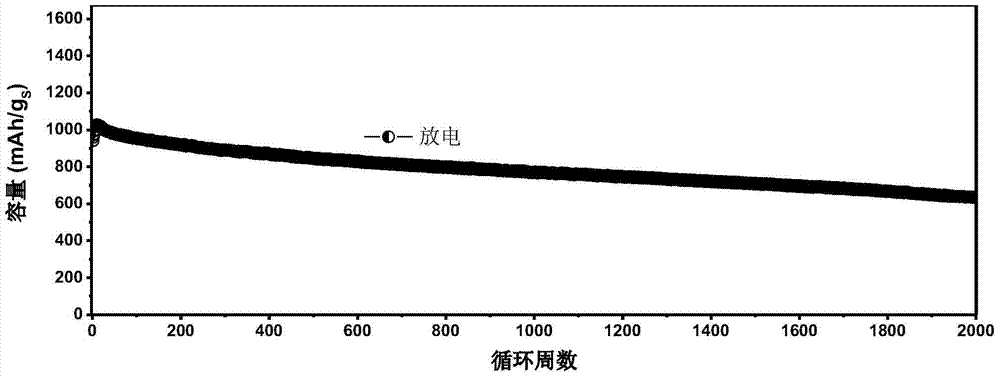

[0075] Dissolve 2.0g of carbon nanotubes in 80mL of aqueous solution containing 6.0g of sodium hydroxide, and conduct a hydrothermal reaction at 180°C for 3 hours in a closed environment to obtain reaction product 1. After centrifuging, the reaction product 1 is separated to obtain a precipitate, and washed with water to pH If it is neutral, a functionalized carbon nanomaterial is obtained. Add 2 g of functionalized carbon nanomaterials into 0.08 mol of sodium thiosulfate aqueous solution, stir well to obtain a mixed solution, add 0.2 mol / L dilute hydrochloric acid dropwise at a rate of 20 μL / min to the mixed solution at 20 ° C, and the dropwise addition ends After reacting at 20°C for 12 hours, the reaction product 2 was obtained. The reaction product 2 was centrifuged and separated to obtain a precipitate, washed with water until the pH was neutral, and dried to obtain a functionalized carbon nanomaterial coated with sulfur on the outside. Add 2 g of functionalized carbon na...

Embodiment 2

[0086] Dissolve 2.0g of carbon nanospheres in 80mL of aqueous solution containing 6.0g of sodium hydroxide, and conduct a hydrothermal reaction at 180°C for 3 hours in a closed environment to obtain reaction product 1. After centrifuging, the reaction product 1 is separated to obtain a precipitate, and washed with water to pH If it is neutral, a functionalized carbon nanomaterial is obtained. Add 2 g of functionalized carbon nanomaterials into 0.08 mol of sodium thiosulfate aqueous solution, stir well to obtain a mixed solution, add 0.2 mol / L dilute hydrochloric acid dropwise at a rate of 20 μL / min to the mixed solution at 20 ° C, and the dropwise addition ends After reacting at 20°C for 12 hours, the reaction product 2 was obtained. The reaction product 2 was centrifuged and separated to obtain a precipitate, washed with water until the pH was neutral, and dried to obtain a functionalized carbon nanomaterial coated with sulfur on the outside. Add 2 g of functionalized carbon ...

Embodiment 3

[0097] Dissolve 2.0g of graphene in 80mL of aqueous solution containing 6.0g of sodium hydroxide, conduct a hydrothermal reaction in a closed environment at 180°C for 3 hours to obtain reaction product 1, centrifuge reaction product 1 and separate to obtain a precipitate, wash with water until the pH is Neutral to obtain functionalized carbon nanomaterials. Add 2 g of functionalized carbon nanomaterials into 0.08 mol of sodium thiosulfate aqueous solution, stir well to obtain a mixed solution, add 0.2 mol / L dilute hydrochloric acid dropwise at a rate of 20 μL / min to the mixed solution at 20 ° C, and the dropwise addition ends After reacting at 20°C for 12 hours, the reaction product 2 was obtained. The reaction product 2 was centrifuged and separated to obtain a precipitate, washed with water until the pH was neutral, and dried to obtain a functionalized carbon nanomaterial coated with sulfur on the outside. Add 2 g of functionalized carbon nanomaterials coated with sulfur on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com