Method for preparing titanate, anatase TiO2 and AgCl/Ag/TiO2 composite material

A composite material and titanate technology, applied in chemical instruments and methods, titanates, titanium compounds, etc., can solve the problems of complex preparation process, low product yield, and high cost, and achieve simple operation process, high yield, and stability. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1. According to the ratio of 50% Al by atomic percentage, and the rest is Ti, put the prepared aluminum and titanium metal blocks into the smelting furnace and heat them to a molten state. After sufficient stirring to alloy them, use argon to melt them The liquid is blown out quickly under the pressure of 0.1MPa, and solidifies quickly on the high-speed rotating copper roller, and the cooling rate is 10 4 K / s, obtain a continuous alloy thin strip with a thickness of 20-40 microns, a width of 2-5 mm, and a length of 50-20 cm.

[0046] 2. Measure 50ml, 10mol / L NaOH solution, then place 0.5g of the obtained Al—Ti alloy strip in NaOH solution for dealloying treatment, control the reaction temperature at 50°C, and alloy the strip after 4 hours of reaction From black to white, dealloying is completed. The product is collected, washed repeatedly with distilled water until neutral, and stored in a vacuum container, which is titanate.

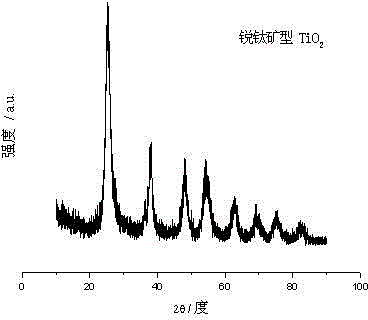

[0047] 3. Take 0.2 g of the collected ti...

Embodiment 2

[0050] 1. Weigh pure aluminum and pure titanium metal blocks (purity ≥ 99.5wt%) according to the atomic percentage of 90% aluminum and 10% titanium, heat to a molten state, and alloy them after sufficient stirring, and use argon to melt the molten The liquid is blown out rapidly under the pressure of 0.1MPa, and solidifies rapidly on the high-speed rotating copper roller, and the cooling rate is 10 4 K / s to obtain a continuous Al—Ti alloy strip with a thickness of 20-40 microns, a width of 2-5 mm, and a length of 50-20 cm.

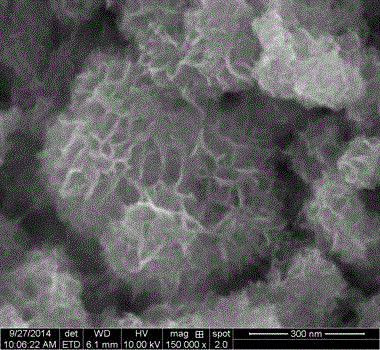

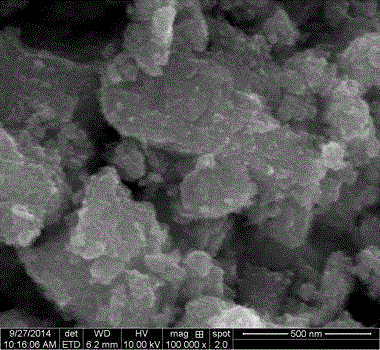

[0051] 2. Measure 50ml of 4mol / L NaOH solution, then place 0.5g of the obtained Al—Ti alloy thin strip in NaOH solution for dealloying treatment, control the reaction temperature at 50°C, and complete dealloying after 5 hours of reaction , collect the product after the reaction, wash it repeatedly with distilled water until neutral, and store it in a vacuum container, which is titanate. The SEM picture of the obtained product is as follows figure 1 As sh...

Embodiment 3

[0053] 1. Weigh pure aluminum and pure titanium metal blocks (purity ≥ 99.5wt%) according to the atomic percentage of 90% aluminum and 10% titanium, heat to a molten state, and alloy them after sufficient stirring, and use argon to melt the molten The liquid is blown out rapidly under the pressure of 0.1MPa, and solidifies rapidly on the high-speed rotating copper roller, and the cooling rate is 10 3 K / s to obtain a continuous Al—Ti alloy strip with a thickness of 20-40 microns, a width of 2-5 mm, and a length of 50-20 cm.

[0054] 2. Measure 50ml of 2mol / L NaOH solution, then place 0.5g of the obtained Al—Ti alloy thin strip in NaOH solution for dealloying treatment, control the reaction temperature at 50°C, and complete dealloying after 24 hours of reaction , collect the product after the reaction, wash it repeatedly with distilled water until neutral, and store it in a vacuum container, which is titanate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com