Metal rust inhibitor and preparation method thereof

A technology of metal anti-rust agent and additives, applied in anti-corrosion coatings, coatings, etc., can solve the problems of unresolved pollution problems, toxicity, human body and environmental hazards, etc., to improve the anti-rust effect and stability, and increase stability , enhance the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of metal antirust agent in the present embodiment comprises the following steps:

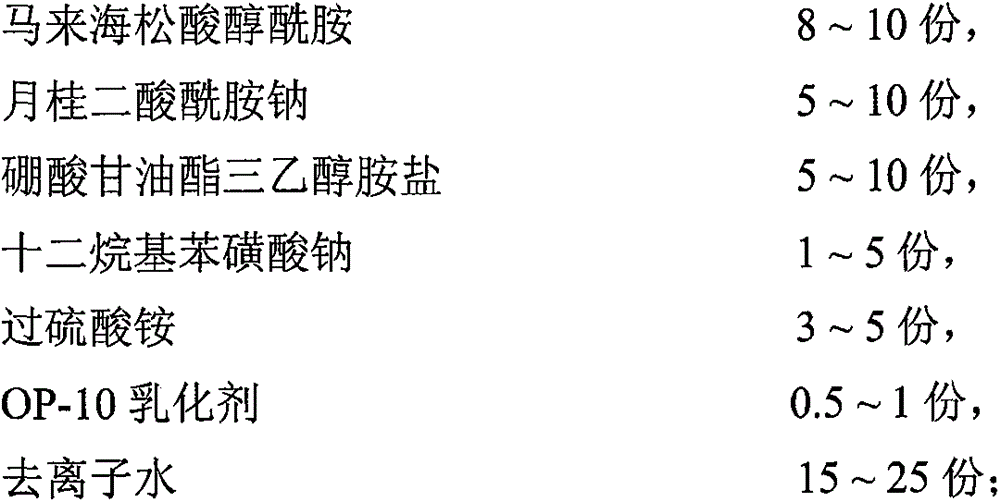

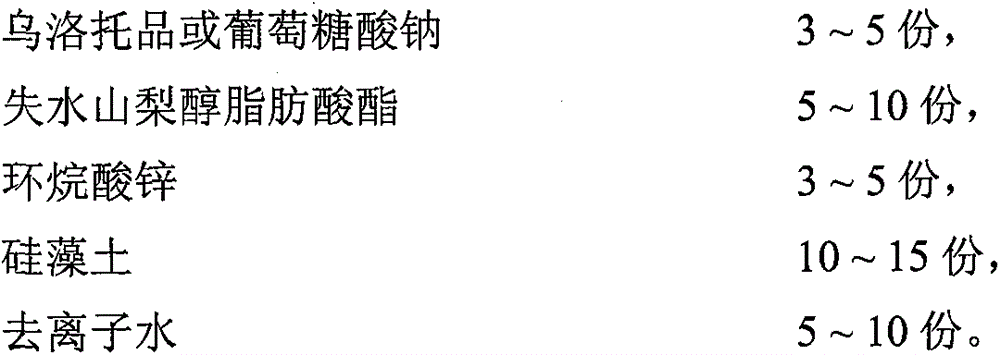

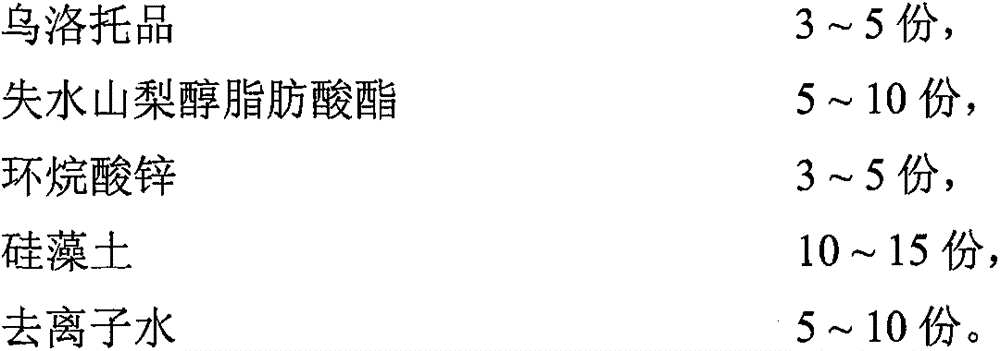

[0030] (1) Preparation of corrosion inhibitor: 8 parts of maleopimaric acid alcohol amide, 5 parts of sodium lauric acid amide, and 5 parts of boric acid glyceride triethanolamine salt are placed in a reactor equipped with a stirrer, and then sequentially added to the reactor Add 1 part of OP-10 emulsifier, 1 part of sodium dodecylbenzene sulfonate, 3 parts of ammonium persulfate and 15 parts of deionized water, stir until evenly mixed, then heat the above reactor in a water bath, the temperature of the water bath is 75 ℃, heat preservation reaction for 1.5h, place the reactor in the room for natural cooling, and adjust the pH of the product in the reactor to 7 when it is cooled to room temperature;

[0031] (2) Add 20 parts of ethanol and 15 parts of polyethylene glycol 200 dimethacrylate into a reaction kettle equipped with a stirrer, stir well and add 3 parts of ...

Embodiment 2

[0034] The preparation method of metal antirust agent in the present embodiment comprises the following steps:

[0035] (1) Preparation of corrosion inhibitor: 8 parts of maleopimaric acid alcohol amide, 8 parts of sodium lauric acid amide, and 5 parts of boric acid glyceride triethanolamine salt are placed in a reactor equipped with a stirrer, and then sequentially added to the reactor Add 1 part of OP-10 emulsifier, 3 parts of sodium dodecylbenzene sulfonate, 3 parts of ammonium persulfate and 25 parts of deionized water, stir until evenly mixed, then heat the above reactor in a water bath, the temperature of the water bath is 77 ℃, keep the reaction for 1 hour, place the reactor in the room to cool naturally, and adjust the pH of the product in the reactor to 7 when it is cooled to room temperature;

[0036] (2) Add 25 parts of ethanol and 15 parts of polyethylene glycol 200 dimethacrylate into a reactor equipped with a stirrer, stir well and add 5 parts of urotropine, 3 pa...

Embodiment 3

[0039] The preparation method of metal antirust agent in the present embodiment comprises the following steps:

[0040] (1) Preparation of corrosion inhibitor: 10 parts of maleopimaric acid alcohol amide, 8 parts of sodium lauric acid amide, 10 parts of boric acid glyceride triethanolamine salt are placed in a reactor equipped with a stirrer, and then sequentially poured into the reactor Add 1 part of OP-10 emulsifier, 3 parts of sodium dodecylbenzene sulfonate, 5 parts of ammonium persulfate and 18 parts of deionized water, stir until evenly mixed, then heat the above reactor in a water bath, the temperature of the water bath is 80 ℃, heat preservation reaction for 0.8h, place the reactor in the room for natural cooling, and adjust the pH of the product in the reactor to 7 when it is cooled to room temperature;

[0041] (2) Add 25 parts of ethanol and 18 parts of polyethylene glycol 200 dimethacrylate into a reaction kettle equipped with a stirrer, stir well and add 5 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com