Active ecological floor and preparation method thereof

An ecological and active technology, which is applied in coatings, buildings, building structures, etc., can solve the problem of not outstanding effect of releasing negative ions, achieve the effect of eliminating harmful gases and improving the quantity and quality of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In the present embodiment, the active ecological floor comprises bamboo-plastic floor and the active ecological paint coated on the floor, wherein,

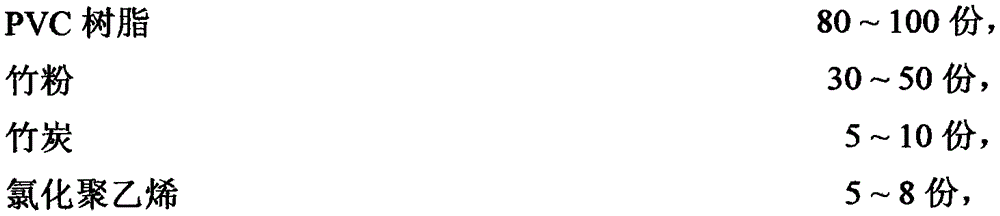

[0029] Bamboo-plastic floor materials include the following components by mass:

[0030]

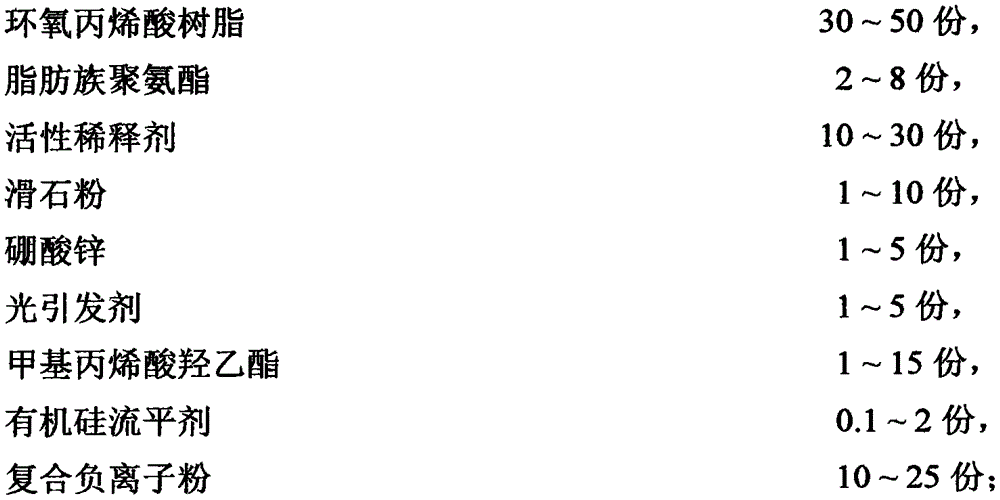

[0031] Active eco-paint consists of the following components by mass:

[0032]

[0033] Above-mentioned composite negative ion powder comprises the following components by mass:

[0034]

[0035] The preparation method of active ecological floor in the present embodiment comprises the following steps:

[0036] (1) Dry bamboo powder and bamboo charcoal at 100°C for 2 hours, adjust the moisture content of bamboo powder and bamboo charcoal to below 3% and put them into the high-speed mixer, and add PVC resin and chlorinated polyethylene to the high-speed mixer in turn , nano-silica, stabilizer HJ-301, glyceryl stearate, polyethylene wax, foaming agent azodicarbonamide, coupling agent triethanolamine borate and plasticizer pol...

Embodiment 2

[0044] In the present embodiment, the active ecological floor comprises bamboo-plastic floor and the active ecological paint coated on the floor, wherein,

[0045] Bamboo-plastic floor materials include the following components by mass:

[0046]

[0047] Active eco-paint consists of the following components by mass:

[0048]

[0049] Composite negative ion powder comprises the following components by mass:

[0050]

[0051]

[0052] The preparation method of above-mentioned active ecological floor comprises the following steps:

[0053] (1) Dry bamboo powder and bamboo charcoal at 110°C for 2.5h, adjust the water content of bamboo powder and bamboo charcoal to be put into the high-speed mixer after adjusting the water content of bamboo powder and bamboo charcoal below 3%, and add PVC resin, chlorinated polyvinyl chloride to the high-speed mixer successively. Ethylene, nano silica, stabilizer HJ-301, glyceryl stearate, polyethylene wax, foaming agent azodicarbonam...

Embodiment 3

[0060] In the present embodiment, the active ecological floor comprises bamboo-plastic floor and the active ecological paint coated on the floor, wherein,

[0061] Bamboo-plastic floor materials include the following components by mass:

[0062]

[0063] Active eco-paint consists of the following components by mass:

[0064]

[0065] Composite negative ion powder comprises the following components by mass:

[0066]

[0067] The preparation method of above-mentioned active ecological floor comprises the following steps:

[0068] (1) Dry bamboo powder and bamboo charcoal at 105°C for 3 hours, adjust the moisture content of bamboo powder and bamboo charcoal to below 3% and put them into the high-speed mixer, and add PVC resin and chlorinated polyethylene to the high-speed mixer in turn , nano-silica, stabilizer HJ-301, glyceryl stearate, polyethylene wax, foaming agent azodicarbonamide, coupling agent triethanolamine borate and plasticizer polyadipate-1, 2-propylene g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com