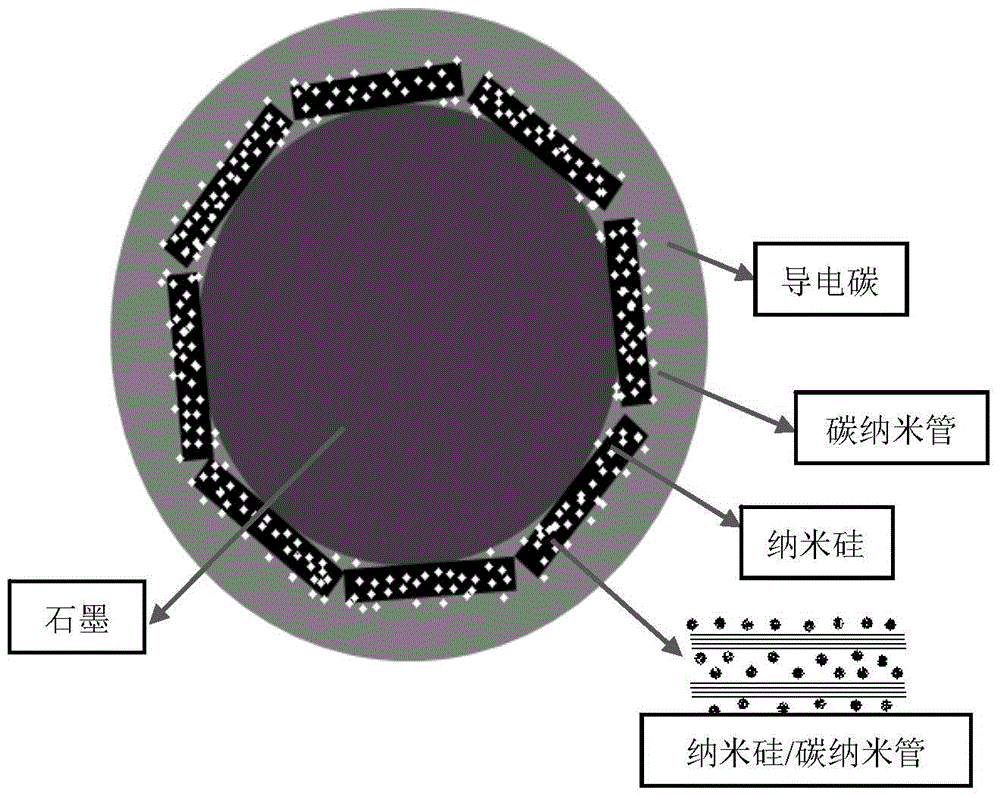

A kind of silicon composite negative electrode material, preparation method and lithium ion battery

A technology of negative electrode materials and composites, which can be used in battery electrodes, secondary batteries, circuits, etc., and can solve the problems of low filling amount, unfavorable commercialization, and large continuous phase size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

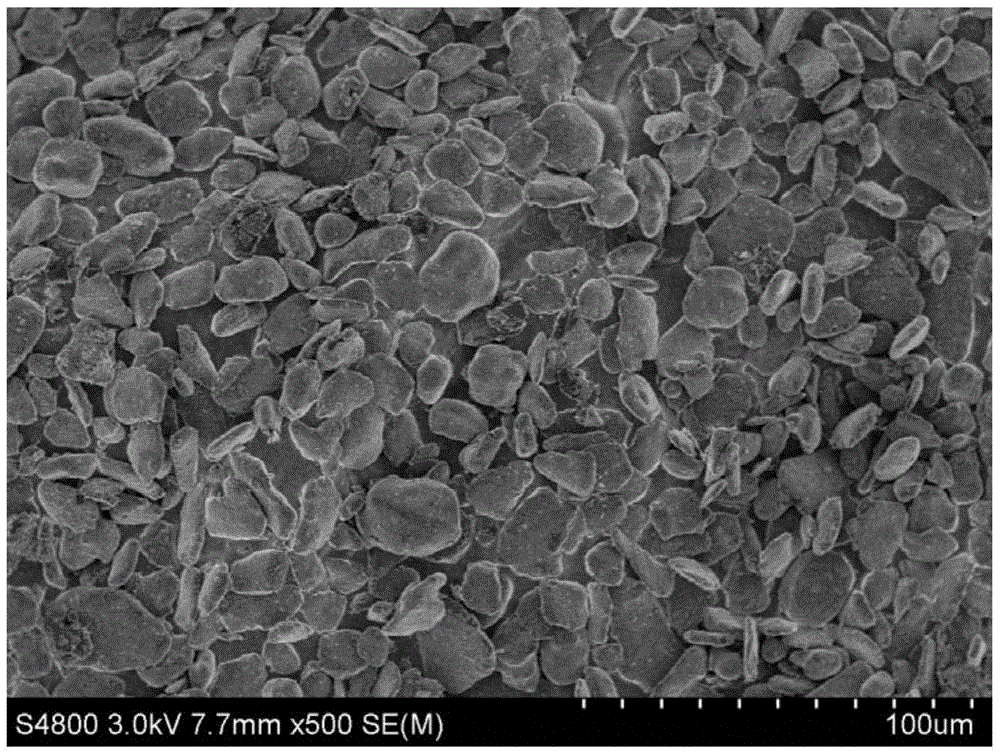

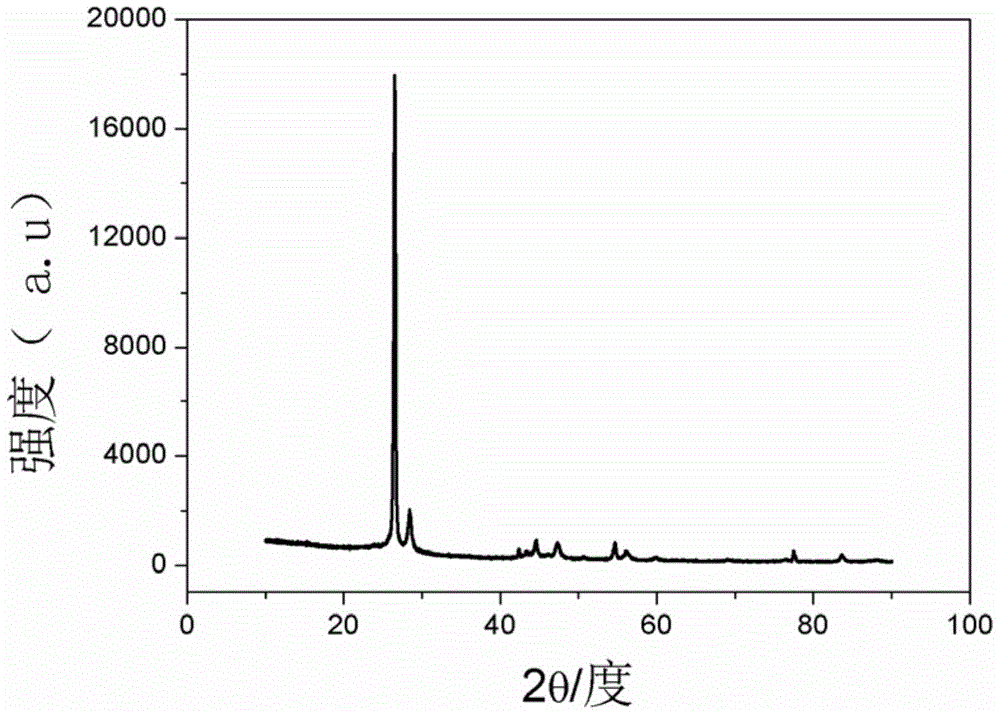

Examples

Embodiment 1

[0091] (1) Preparation of the first precursor

[0092] First, in the pretreatment process, the median diameter of 60-120nm multi-walled carbon nanotubes is added to a flask filled with a mixed solution of concentrated nitric acid / concentrated sulfuric acid with a volume ratio of nitric acid:concentrated sulfuric acid=3:1, and after stirring , placed in an ultrasonic cleaner for ultrasonic oxidation for 10 hours, and finally suction filtered and dried in a vacuum oven at 90°C for 12 hours to obtain pure black powder of oxidized carbon nanotubes with open ports and defects;

[0093] Secondly, the carbon nanotube filling process is to disperse the oxidized carbon nanotubes, silicon and fatty acid polyethylene glycol ester with a median particle size of 10-30nm in acetone at a mass ratio of 20:10:0.5, and mechanically stir and mix After 2 hours, inject it into a high-pressure container, and feed nitrogen into it to increase the pressure in the container to 4.0x10 6 Pascal, kept f...

Embodiment 2

[0101] (1) Preparation of the first precursor

[0102] First, in the pretreatment process, the median diameter of 60-120nm multi-walled carbon nanotubes is added to a flask filled with a mixed solution of concentrated nitric acid / concentrated sulfuric acid with a volume ratio of nitric acid:concentrated sulfuric acid=3:1, and after stirring , placed in an ultrasonic cleaner for ultrasonic oxidation for 10 hours, and finally suction filtered and dried in a vacuum oven at 90°C for 12 hours to obtain pure black powder of oxidized carbon nanotubes with open ports and defects;

[0103] Secondly, the carbon nanotube filling process is to disperse the oxidized carbon nanotubes, silicon and gull gum with a median particle size of 10 to 30 nm in acetone at a mass ratio of 5:1:0.5, and mechanically stir and mix for 2 hours. Inject it into a high-pressure container, and pass nitrogen into it to increase the pressure in the container to 4.0x10 6 Pascal, kept for 24 hours, finally suction...

Embodiment 3

[0110] (1) Preparation of the first precursor

[0111] First, in the pretreatment process, the median diameter of 60-120nm multi-walled carbon nanotubes is added to a flask filled with a mixed solution of concentrated nitric acid / concentrated sulfuric acid with a volume ratio of nitric acid:concentrated sulfuric acid=3:1, and after stirring , placed in an ultrasonic cleaner for ultrasonic oxidation for 10 hours, and finally suction filtered and dried in a vacuum oven at 90°C for 12 hours to obtain pure black powder of oxidized carbon nanotubes with open ports and defects;

[0112] Secondly, the carbon nanotube filling process is to disperse the oxidized carbon nanotubes, silicon and polyvinylpyrrolidone with a median particle size of 10 to 30 nm in acetone at a mass ratio of 40:20:0.5, and mechanically stir and mix for 2 hours. Inject it into a high-pressure container, and pass nitrogen into it to increase the pressure in the container to 4.0x10 6 Pascal, kept for 24 hours, f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com