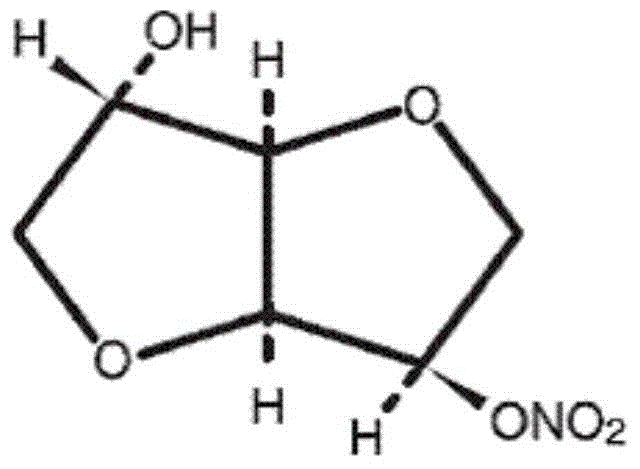

Isosorbide mononitrate sustained release tablets and preparation process thereof

A technology of isosorbide dinitrate and sustained-release tablets, which is applied in the directions of non-active ingredients medical preparations, cardiovascular system diseases, pharmaceutical formulations, etc. Inhomogeneous and other problems, to achieve the effect of good drug release stability, no membrane aging, and high bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

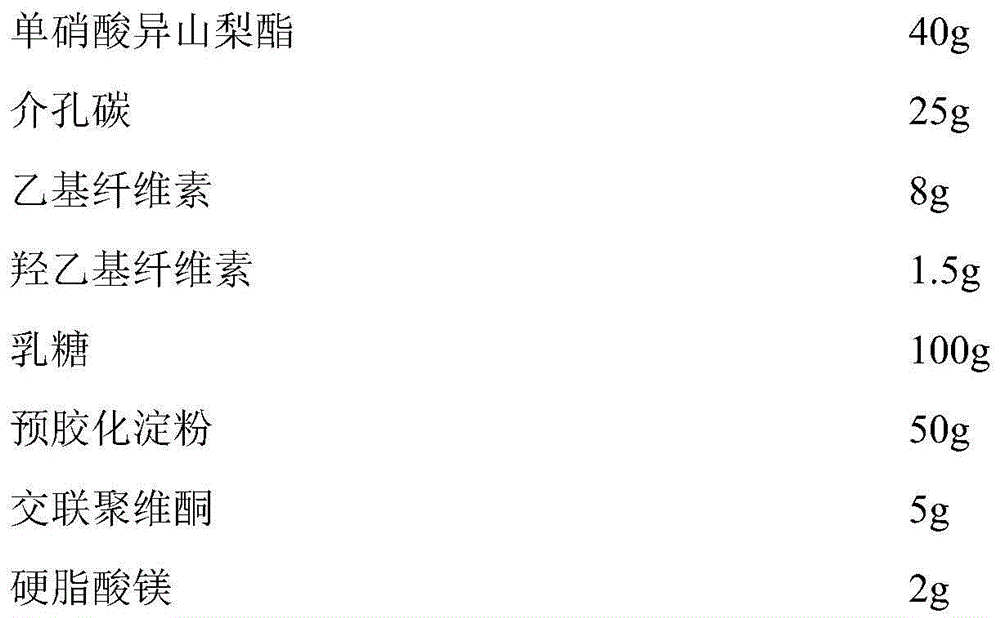

Embodiment 1

[0031]

[0032] Preparation Process:

[0033] ① Dissolve raw material isosorbide mononitrate in water, add mesoporous carbon (specific surface area is 1018m 2 / g, the pore volume is 0.51cm 3 / g), continuous stirring, ultrasound, after the drug enters the mesoporous carbon channel to reach equilibrium, spray drying to remove the solvent, and obtain the raw material-mesoporous carbon composite;

[0034] ②Put the raw material-mesoporous carbon composite into the fluidized bed, preheat the material to a temperature of about 34°C, and use the acetone-water (volume ratio 8:2) solution of ethyl cellulose and hydroxyethyl cellulose (solid content 5%) bottom spray coating to prepare sustained-release coated pellets, and the weight gain of the coating is 14.6% (the coating film accounts for the weight percentage of the raw material-mesoporous carbon composite);

[0035] ③Mix the sustained-release coated pellets with lactose, pregelatinized starch, crospovidone, and magnesium steara...

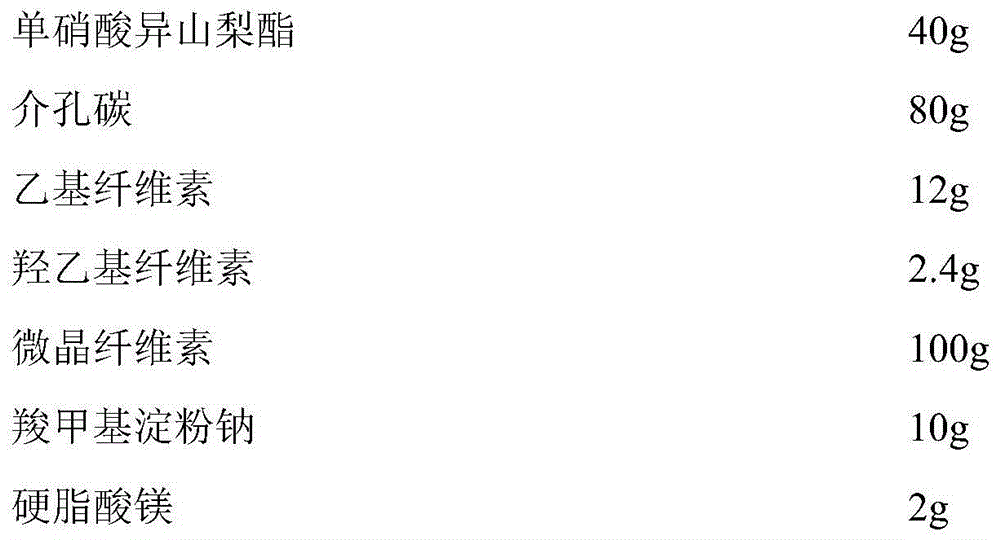

Embodiment 2

[0037]

[0038] Preparation Process:

[0039] ① Dissolve raw material isosorbide mononitrate in water, add mesoporous carbon (specific surface area is 1058m 2 / g, the pore volume is 0.86cm 3 / g), continuous stirring, ultrasound, after the drug enters the mesoporous carbon channel to reach equilibrium, spray drying to remove the solvent, and obtain the raw material-mesoporous carbon composite;

[0040] ②Put the raw material-mesoporous carbon composite into the fluidized bed, preheat the material to a temperature of about 34°C, and use the acetone-water (volume ratio 8:2) solution of ethyl cellulose and hydroxyethyl cellulose (solid content 5%) bottom spray coating to prepare sustained-release coated pellets, and the weight gain of the coating is 12% (the coating film accounts for the weight percentage of the raw material-mesoporous carbon composite);

[0041] ③Mix the sustained-release coated pellets with microcrystalline cellulose, sodium carboxymethyl starch, and magnesiu...

Embodiment 3

[0043]

[0044]

[0045] Preparation Process:

[0046] ① Dissolve raw material isosorbide mononitrate in water, add mesoporous carbon (specific surface area is 1018m 2 / g, the pore volume is 0.51cm 3 / g), continuous stirring, ultrasound, after the drug enters the mesoporous carbon channel to reach equilibrium, spray drying to remove the solvent, and obtain the raw material-mesoporous carbon composite;

[0047] ②Put the raw material-mesoporous carbon composite into the fluidized bed, preheat the material to a temperature of about 34°C, and use the acetone-water (volume ratio 8:2) solution of ethyl cellulose and hydroxyethyl cellulose (solid content 5%) bottom spray coating to prepare sustained-release coated pellets, and the coating weight increased to 7.5% (the coating film accounts for the weight percentage of the raw material-mesoporous carbon composite);

[0048] ③Mix the sustained-release coated pellets with microcrystalline cellulose, starch, croscarmellose sodium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com