Preparation method of perovskite film stable in air

A perovskite and thin film technology, which is applied in the field of preparation of perovskite thin films, can solve the problems of battery efficiency attenuation, hindering the promotion of battery production, poor stability, etc., and achieve the effect of simple steps and convenient control of process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

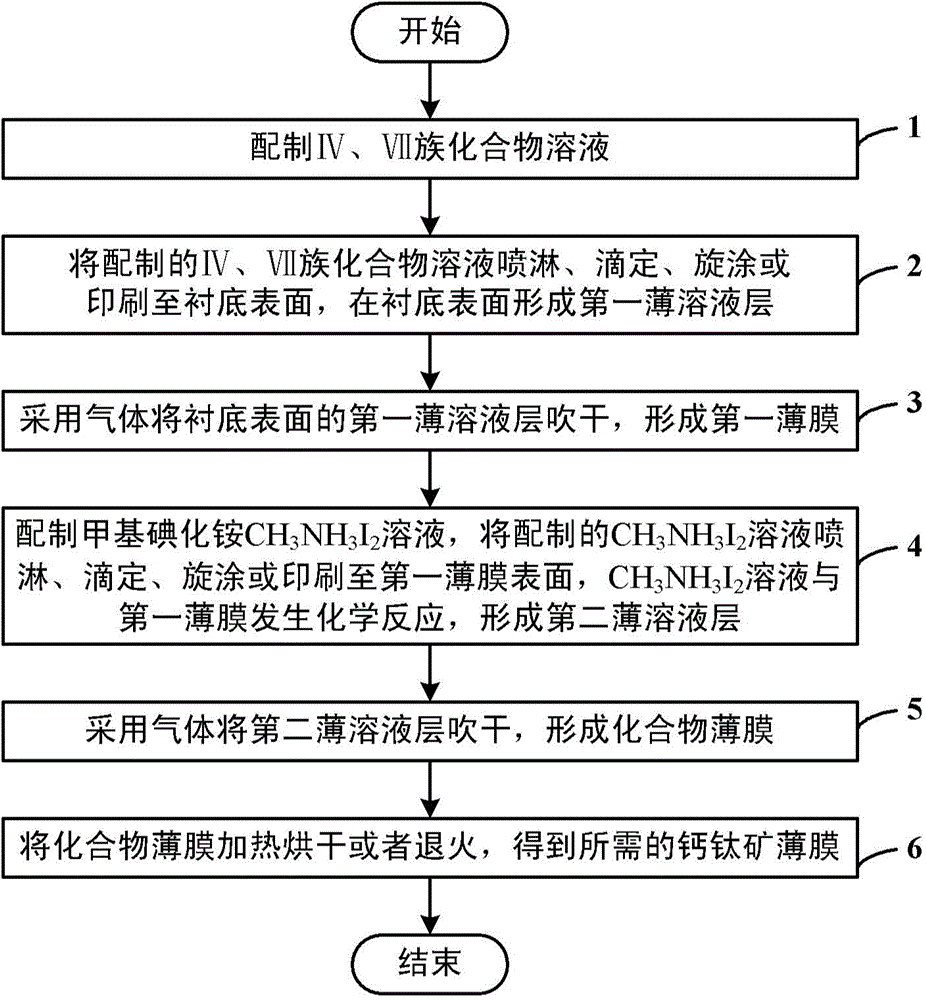

[0042] Such as figure 1 as shown, figure 1 It is a flow chart of the preparation method scheme one of the perovskite thin film stably existing in the air provided by the present invention, and the method comprises the following steps:

[0043] Step 1: Prepare IV and VII group compound solutions; the solute is lead iodide, lead chloride, lead bromide, tin iodide, tin chloride, tin bromide, germanium iodide, germanium chloride or germanium bromide At least one, the solvent is at least one of dimethylformamide, dimethyl sulfoxide, methanol, ethanol, ethylene glycol, isopropanol, n-butanol, acetone, toluene, chlorobenzene or chloroform, mixed solution The concentration is 0.01-1000mmol / ml, and the mixed solution is heated to 30-200°C, and the heating time is 5 minutes-24 hours;

[0044] Step 2: Spray, titrate, spin-coat or print the prepared IV and VII compound solution onto the substrate surface to form the first thin solution layer on the substrate surface; the substrate can b...

Embodiment 1

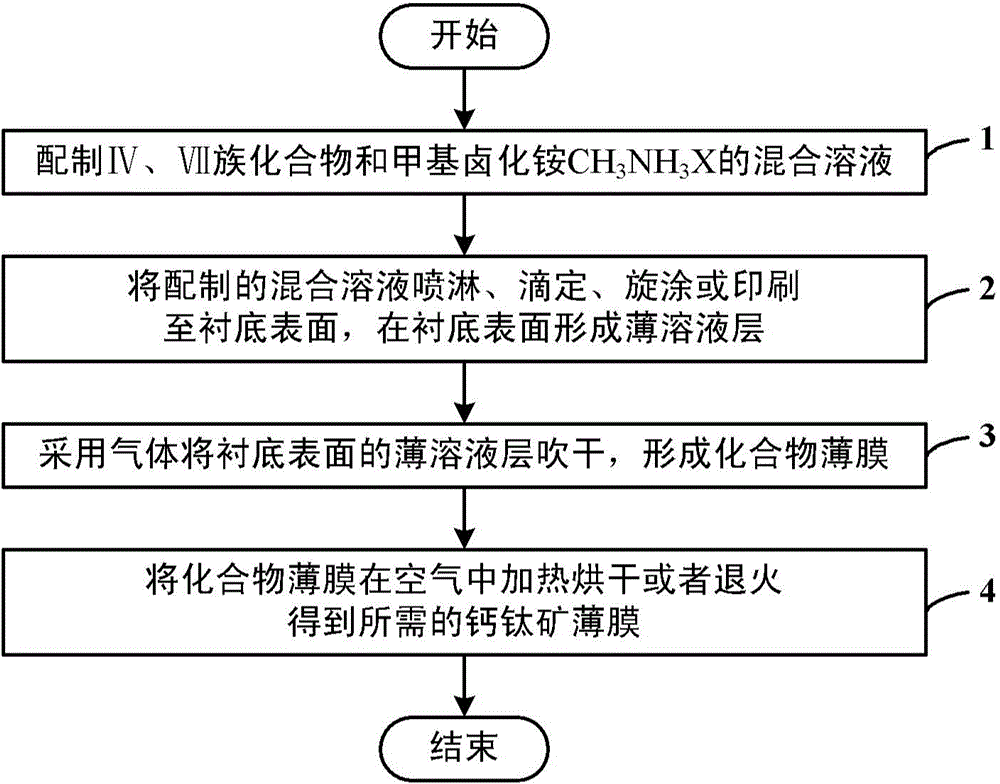

[0056] Refer to the above figure 2 In the scheme two shown, this embodiment is a method for preparing a perovskite thin film that exists stably in the air, comprising the following steps:

[0057] (1) Preparation of lead iodide PbI 2 , methyl ammonium iodide CH 3 NH 3 The DMF mixed solution of I, concentration is respectively 12mmol / ml and 36mmol / ml, and solution is heated to 100 ℃, and heating time is 3 hours;

[0058] (2) The solution is titrated onto the surface of the fluorine-doped tin oxide FTO substrate to form a thin solution layer;

[0059] (3) Use nitrogen to dry the thin solution layer to form a compound film; the gas pressure is 0.05-10 MPa, and the gas flow rate is 20 sccm; the distance between the film surface and the gas outlet is 10 cm;

[0060] (4) Heat and dry the compound film in the air at a temperature of 160°C for 10 minutes to obtain the desired perovskite CH 3 NH 3 PB 3 film.

Embodiment 2

[0062] Refer to the above figure 1 In the scheme one shown, this embodiment is a method for preparing a perovskite thin film that exists stably in the air, comprising the following steps:

[0063] (1) with lead iodide PbCl 2 DMF solution with a concentration of 12mmol / ml, the solution was heated at 50°C for 5 hours;

[0064] (2) The solution is titrated onto the surface of the aluminum-doped zinc oxide AZO substrate to form the first thin solution layer;

[0065] (3) adopt argon gas to dry the first thin solution layer on the substrate surface to form the first film; the gas pressure is 0.5MPa, the flow rate is 10sccm, and the facing distance between the substrate surface and the gas outlet is 3cm;

[0066] (4) Preparation of methyl ammonium iodide CH 3 NH 3 Cl solution, the concentration is 15mmol / ml, the prepared CH 3 NH 3 I 2 The solution is sprayed onto the surface of the first film, CH 3 NH 3 The I solution reacts chemically with the first film to form a second t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com