Highly dispersed nano molybdenum disulfide catalyst synthetic method

A technology of nano-molybdenum disulfide and synthesis method, which is applied in the field of synthesis of highly dispersed nano-molybdenum disulfide catalyst, can solve the problem that the dispersibility of molybdenum disulfide cannot be guaranteed, the exposure of catalyst reaction active sites is affected, and the dispersibility of molybdenum disulfide is unknown. and other problems, to achieve the effect of high sphericity, short production cycle and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

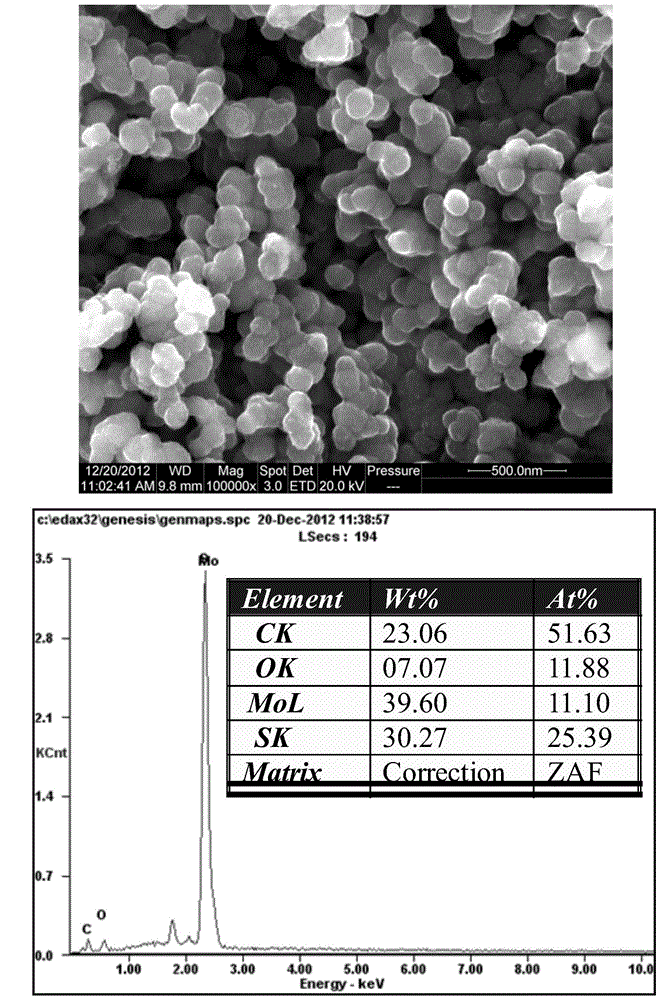

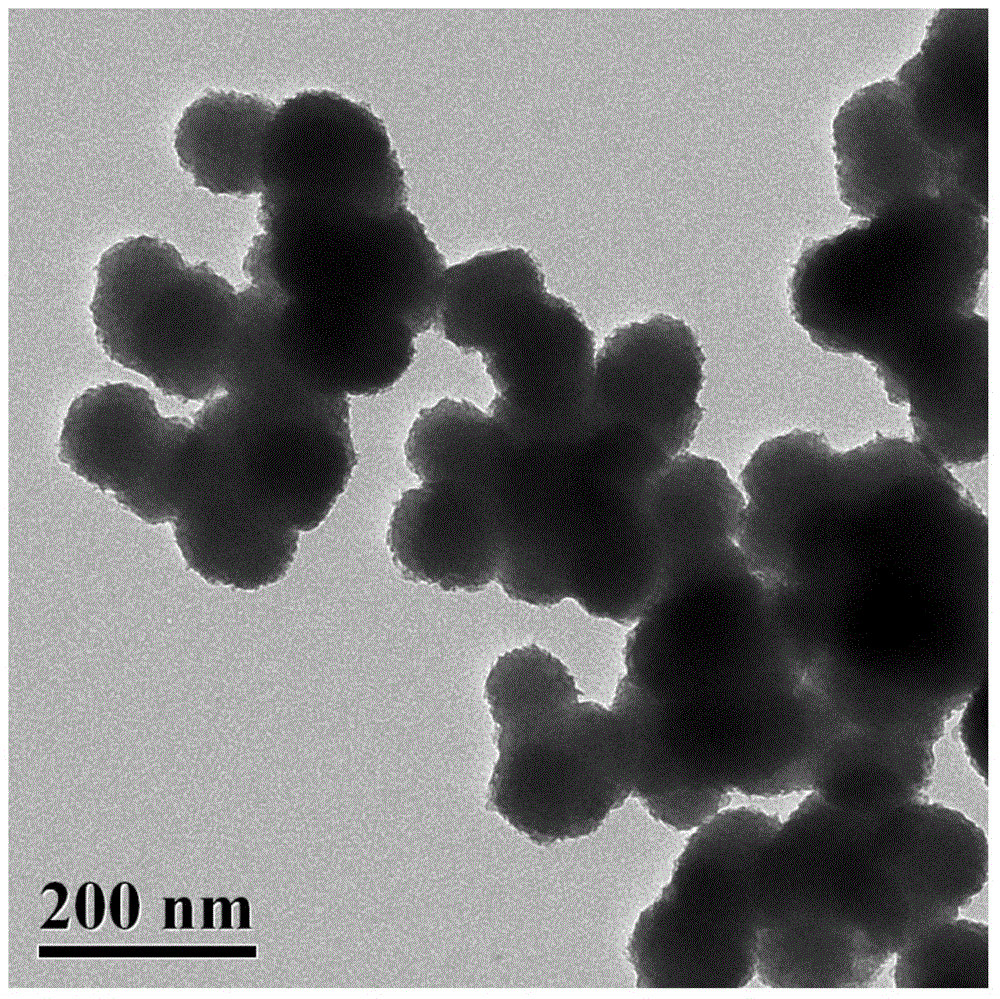

Embodiment 1

[0019] Add 0.1066-1.0660 g of self-made ammonium tetrathiomolybdate into 64 ml of diethanol solution, and continuously stir to obtain a dark red transparent solution. Add 6ml of hydrazine hydrate as reducing agent, stir to make it evenly mixed. Transfer the prepared solution to the lining of a polytetrafluorohydrothermal kettle, put it into a stainless steel hydrothermal reaction kettle and seal it, and then place the reaction kettle in an oven at 160°C for 6 hours of reaction. After the reaction is finished, cool to room temperature, transfer the reaction solution into a beaker, add an appropriate amount of acetone to settle the reaction product, remove the supernatant after precipitation, filter with suction, wash and dry to obtain a nanometer molybdenum disulfide catalyst for use.

Embodiment 2

[0021] Add 0.1773g of self-made ammonium tetrathiomolybdate into 64ml of water, methanol, ethanol or ethylene glycol solution, and continuously stir to obtain a dark red transparent solution. Add 6ml of 80% hydrazine hydrate as reducing agent, stir to mix evenly, the concentration of molybdenum source solution is 0.008mol / L. Transfer the configured solution into a polytetrafluoroethylene liner, put it into a reaction kettle and seal it, and then place the reaction kettle in an oven at 160°C for 6 hours of reaction. After the reaction is finished, cool to room temperature, transfer the reaction solution into a beaker, add an appropriate amount of acetone to settle the reaction product, remove the supernatant after precipitation, filter with suction, wash and dry to obtain a nanometer molybdenum disulfide catalyst for use.

Embodiment 3

[0023] Add 0.1773g of self-made ammonium tetrathiomolybdate into 64ml of diethanol solution, and stir continuously to obtain a dark red transparent solution. Add 6ml of hydrazine hydrate as a reducing agent, stir to make it evenly mixed, and the concentration of the molybdenum source solution is 0.008mol / L. Put the prepared solution into the polytetrafluoroethylene liner, put it into the reaction kettle and seal it, then put the reaction kettle in an oven at 120-160°C, and react for 1-12 hours. After the reaction is finished, cool to room temperature, transfer the reaction solution into a beaker, add an appropriate amount of acetone to settle the reaction product, remove the supernatant after precipitation, filter with suction, wash and dry to obtain a nanometer molybdenum disulfide catalyst for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com