Semi-insulated GaN film and preparation method thereof

A semi-insulating, thin-film technology, used in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as reducing the electron migration rate, and achieve the effects of low cost, high purity, and simple operation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

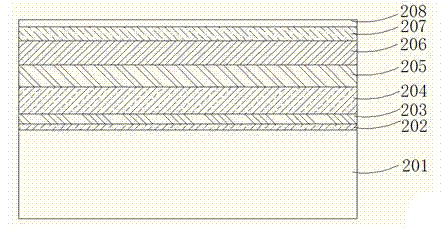

[0025] Such as figure 1 As shown, the present invention provides a method for preparing a semi-insulating GaN thin film, which includes the following steps: first, a sapphire substrate 101 with a (0001) crystal orientation is placed in an MOCVD reaction chamber; 2 In the environment, the temperature is raised to 1180°C for high-temperature treatment of the substrate for 10 minutes; the temperature is lowered to 550°C, and a 25nm thick GaN buffer layer 102 is grown at 600mbar; the temperature is raised to 1150°C to grow a 2um thick non-doped GaN template 103; Under 50torr, carbon tetrachloride doping gas was introduced to grow a carbon concentration of 1×10 18 cm -3 3um thick semi-insulating gallium nitride thin film layer 104; cool down to room temperature, and the growth ends.

Embodiment 2

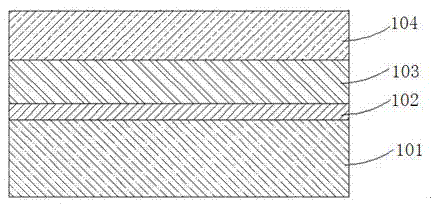

[0027] Such as figure 2 As shown, the structure schematic diagram of the high electron mobility transistor epitaxial material prepared by the present invention. First, put the silicon substrate 201 into the growth chamber of the MOCVD system; then in the H 2 In the environment, the temperature was raised to 1180°C for high-temperature treatment of the substrate for 10 minutes; the temperature was lowered to 1060°C, and trimethylaluminum was passed through for 20 seconds to form an Al layer 202 on the surface of the silicon substrate; ammonia gas and trimethylaluminum were passed through to grow a 100nm AlN layer 203; Ammonia gas, trimethylaluminum and trimethylgallium are introduced to grow a 0.5um thick AlGaN layer 204; Trimethylaluminum is turned off, and the temperature is raised to 1150°C to grow a 1.0um thick non-doped GaN template 205; At 1150°C and 600torr, carbon tetrabromide doping gas was introduced to grow a carbon concentration of 1×10 18 cm -3 2um thick semi-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com