Graphene sponge used for enriching heavy metals or removing pollutants in water and preparation method of graphene sponge

A graphene sponge, water removal technology, applied in the directions of alkali metal compounds, alkali metal oxides/hydroxides, water/sewage treatment, etc. Increase adsorption capacity, no secondary pollution, stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

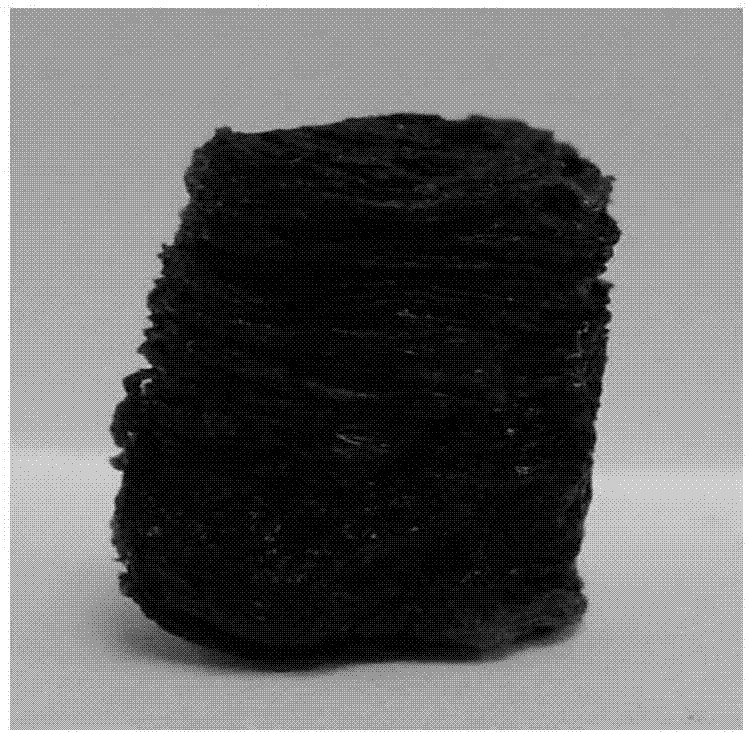

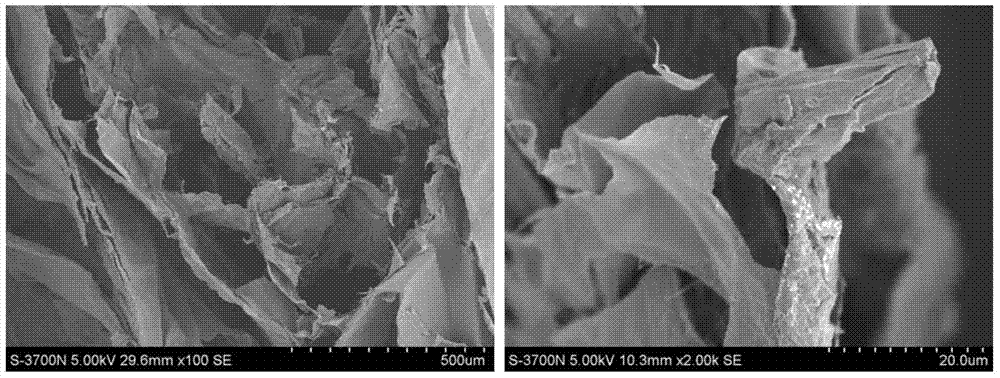

[0030] Embodiment 1: the preparation of the graphene sponge that is used for heavy metal enrichment

[0031] 1. Preparation of Graphene Oxide Solution

[0032] Prepare graphene oxide by the method of Hummer's, specifically 10g graphene is joined in the flask that 500mL vitriol oil / concentrated nitric acid (volume ratio 10 / 1) is housed, slowly add 22g potassium permanganate again under stirring, stir Mix well, cool down, and react at 50°C for 10 hours, add 500mL water and 8mL hydrogen peroxide with a mass fraction of 30% in an ice bath, let stand for 2 hours, then centrifuge with water, 30% hydrochloric acid, water, and ethanol in sequence Wash and dry to obtain graphene oxide.

[0033] Add ionized water to the graphene oxide prepared above, disperse it uniformly by ultrasonication for 1 hour, and prepare a 5 mg / mL graphene oxide aqueous solution.

[0034] 2. Preparation of graphene sponge

[0035] Take five test tubes, add 2 mL of the 5 mg / mL graphene oxide solution obtaine...

Embodiment 2

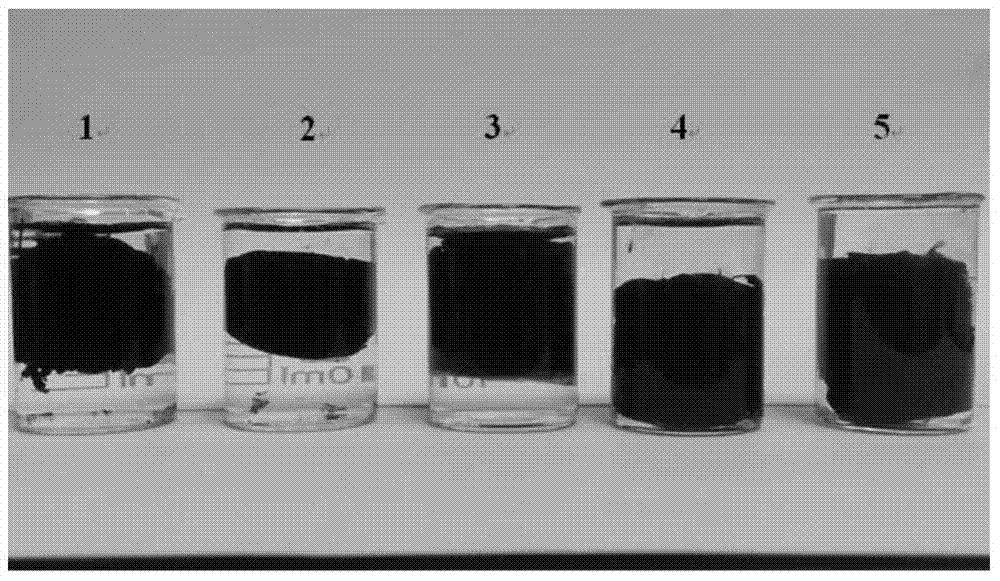

[0036] The application of embodiment 2 graphene sponge in absorbing organic matter in water

[0037]Take five test tubes, respectively prepare 10 mL of reaction solution with graphene oxide concentration of 4.0 mg / mL and sodium alginate concentration of 2 mg / mL, and ultrasonically mix the graphene oxide and sodium alginate solutions, and add sodium bicarbonate solution to adjust the pH to 10, sonicate for 30 minutes, and then put the five test tubes into a 150°C water bath and heat them for 0.5, 2.5, 5.0, 7.5 and 10 hours respectively. After heating, cool and add 500uL 1M calcium chloride solution under stirring to obtain a shaped water-containing graphene sponge. Wash the shaped water-containing graphene sponge with hydrochloric acid and water respectively, and then freeze-dry for 8 hours to obtain five different reaction times. Under the graphene sponge. Add 10 mg of graphene sponges under the above five different reaction times into five containers containing 100 mL of 10 ...

Embodiment 3

[0038] The application of embodiment 3 graphene sponge in adsorption heavy metal ion

[0039] Take five test tubes, respectively prepare 10 mL of reaction solution with graphene oxide concentration of 2.0 mg / mL and sodium alginate concentration of 4 mg / mL, and ultrasonically mix the graphene oxide and sodium alginate solutions, and add sodium bicarbonate solution to adjust the pH to 10, sonicate for 1 hour, and then heat the five test tubes in water baths at 60, 90, 100, 120 and 150°C for 3 hours. After heating, cool and add 500uL 1M calcium chloride solution under stirring to obtain a shaped water-containing graphene sponge. Wash the shaped water-containing graphene sponge with hydrochloric acid and water respectively, and then freeze-dry for 8 hours to obtain five different reaction temperatures. Under the graphene sponge. 10mg of graphene sponges at the above five different reaction temperatures were added to the five to contain Pb 2+ 、Cd 2+ , Hg 2+ and As 3+ (Concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com