Method for continuously preparing fructo-oligosaccharide by using immobilized enzyme microreactor

A microreactor and fructooligosaccharide technology, which is applied in the field of biocatalysis, can solve the problems of uncontinuous production and low reaction intensity, and achieve the effects of expanding production capacity, improving reaction efficiency and good industrialization prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

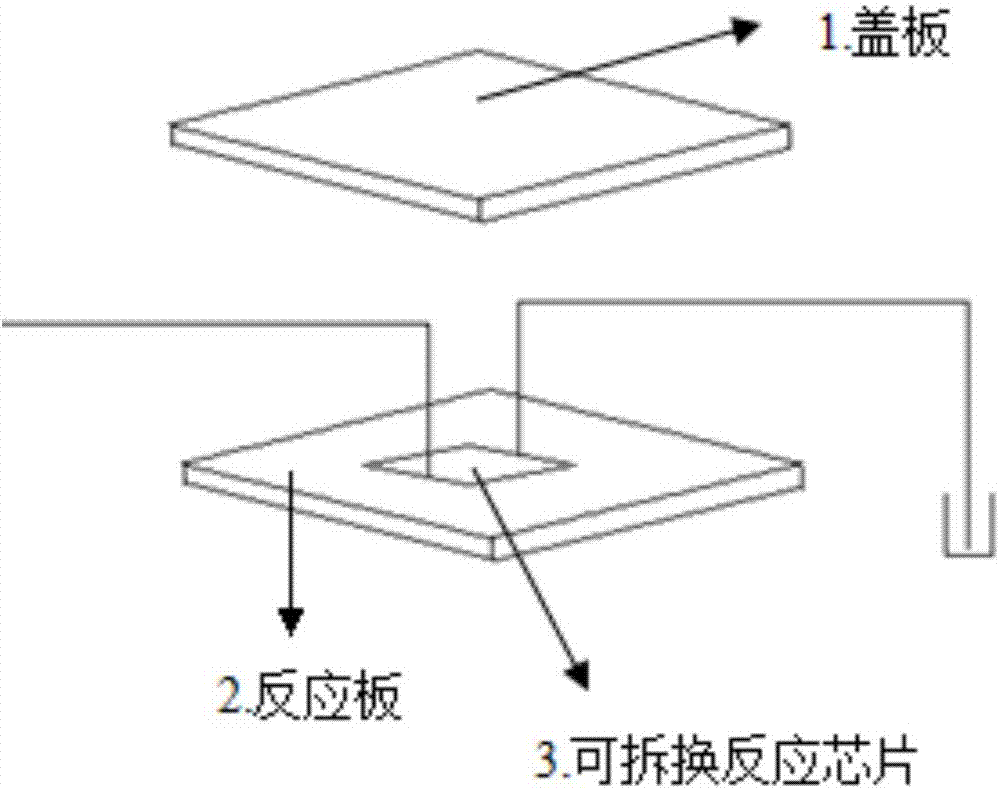

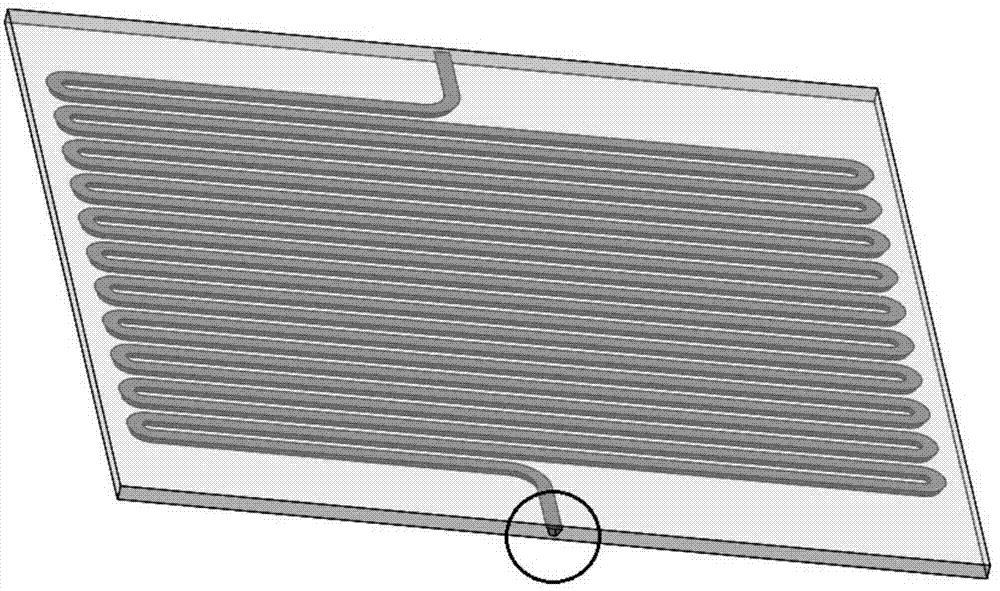

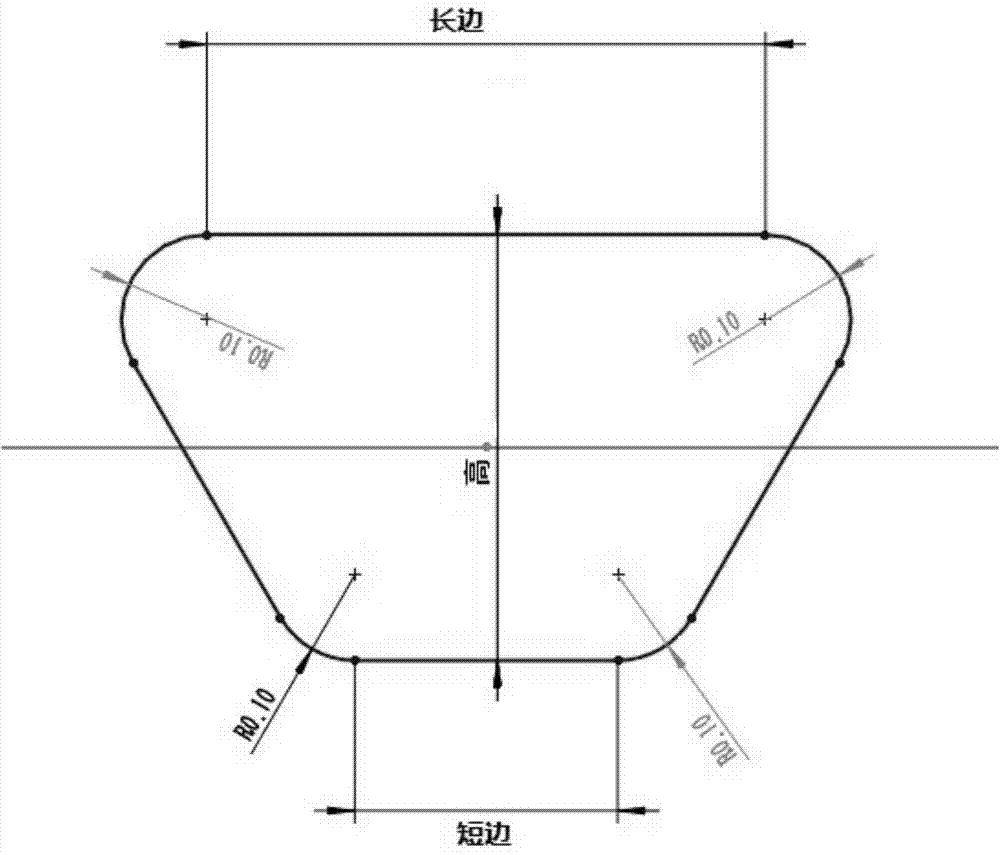

[0025] Depend on figure 1 Shown, the microreactor of the present invention is made up of cover plate 1 and reaction plate 2, contains removable microchannel chip 3 in the groove of reaction plate center, by figure 2 It can be seen that the microchannel chip 3 is engraved with a channel tightly meandering, the upper surface of the channel is open, the lower surface and sides of the channel are closed, the total length of the channel is 50-200mm, and the cut surface of the channel is a trapezoidal structure with a wide top and a narrow bottom ( image 3 ), the long side of the trapezoid is 0.5-1.5mm, the short side is 0.1-0.4mm, and the height is 0.3-1.0mm, the four corners of the trapezoid are rounded, and the rounded diameter is 0.1mm; A fixing clip is provided between the cover plate 1 and the reaction plate 2 of the reactor to prevent side leakage of the solution, wherein the material of the cover plate is glass or stainless steel, and the material of the reaction plate is ...

Embodiment 2

[0027] 1g TiO 2 Disperse in 50ml of toluene, add 5ml of 3-mercaptopropyltrimethoxysilane, and reflux in an oil bath at 110°C for 8h. The sample was suction filtered and washed several times with toluene; the filtered sample was placed in a Soxhlet extractor and extracted with ethanol at reflux temperature for 24 hours to remove unreacted coupling agent; after suction filtration, the sample was taken out at 60 After drying at ℃ for 24h, SH-TiO can be obtained 2 .

[0028] Apply polydimethylsiloxane sol to the inside of the cover plate, and then use a sieve plate with an aperture of 800 mesh to filter the SH-TiO 2The powder is evenly distributed on the polydimethylsiloxane sol, and baked in an oven at 60-80°C for 100-200min to solidify the sol.

[0029] Inject the inulin endoenzyme solution into the removable microchannel chip 3, control the flow rate at 1-100 μL / min, and keep the retention time at 1-5 hours, rinse the excess enzyme solution with ultrapure water to realize th...

Embodiment 3

[0032] The device structure is as in Example 1, 5ml of an aqueous solution with an inulin content of 5wt%, and sulfuric acid to adjust the pH to 4.6, and the reaction system is continuously pumped into the microreactor by a syringe pump at a flow rate of 100 μL / min. The flow channel in the microreactor is a trapezoidal structure with a wide top and a narrow bottom. The long side is 0.5mm, the short side is 0.1mm, the height is 0.5mm, and the channel length is 50mm. 20mg, the reaction temperature is controlled at 55°C, and the retention time of the reaction feed liquid circulating and continuously flowing in the reactor is 4h. The yield of fructo-oligosaccharide prepared by enzymatic degradation was 99.5% detected by HPLC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com