Method for production and recovery of precious metals on the basis of pickling sludge

A technology for pickling sludge and precious metals, which is applied to the removal of copper sulfate, nickel sulfate, and solid waste. It can solve the problems of small and impossible pickling sludge reduction, harmlessness and resource utilization, and achieve Reduce energy consumption, reduce the chance of secondary pollution, and achieve zero emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

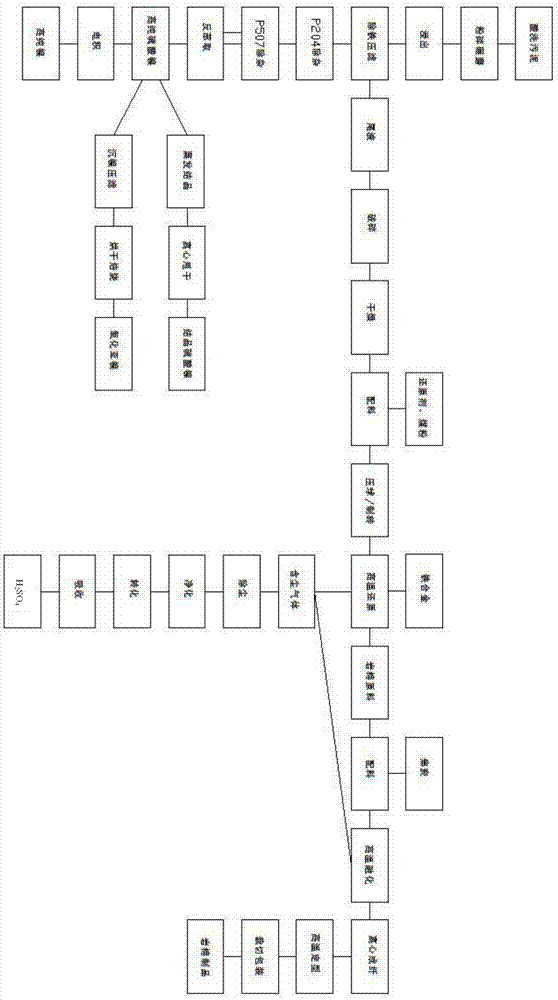

[0027] A kind of method based on pickling sludge production recovery precious metal as shown in Figure 1, comprises the following steps,

[0028]Step 1. Pulverize the pickling sludge with a pulverizer, and then perform leaching treatment. Add sulfuric acid with a pH value of 1.5-2.5 to the pulverized raw material, heat with steam, and stir while heating. The leaching time is 4-8 hours. Wherein, the leached residue is filtered by a filter press, and the filtrate enters the next process step. Step 2, iron removal press filtration, first oxidize ferric oxide to ferric iron in an oxidant hydrogen peroxide solution with a pH value of 3.0-3.5 and a temperature of 25°C, and then add sodium sulfate with a pH value of 3.0-3.5 The oxidant hydrogen peroxide solution is used to precipitate and separate the complexes of Fe3+ and Na+, and the mother liquor enters the next process step through pressure filtration. Step 3, one-time impurity removal, the filtrate after iron removal is filtere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com