Preparation method of high-biocompatibility dual-target modified Fe3O4 nano material

A technology of biocompatibility and nanomaterials, applied in the field of preparation of functional Fe3O4 nanomaterials, can solve problems such as cumbersome synthesis steps and poor target recognition ability, achieve high relaxation rate, good biocompatibility, and facilitate The effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

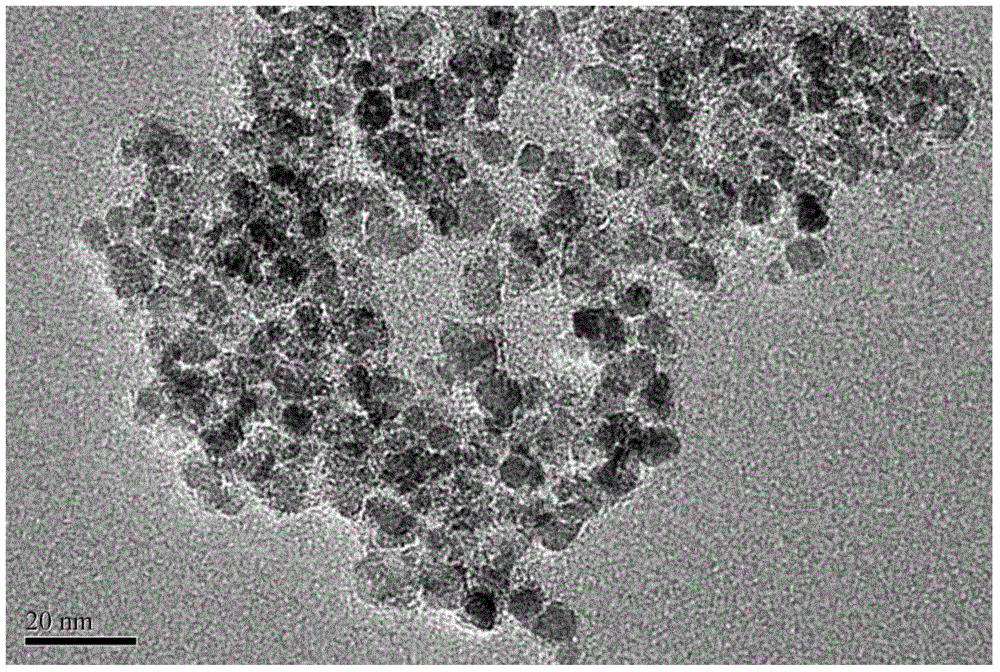

[0022] A dual-target modified Fe with good biocompatibility 3 o 4 The preparation method of nanometer material, the steps are as follows:

[0023] 1) In a 100mL three-neck round bottom flask, 0.5g FeCl 3 ·6H 2 O and 0.184 g FeCl 2 4H 2 O dissolved in 20mLH 2 O, dissolved by mechanical stirring, and protected by nitrogen gas. After 15min, adding 7.5mL mass concentration to the above solution was 27%NH 4 OH, then add 5mL hyaluronic acid (molecular weight 6k Da, 40mg / mL), and continue the reaction at room temperature for 30min.

[0024] 2) the obtained hyaluronic acid modified Fe 3 o 4 The nanomaterials were washed four times with high-purity water using an external magnetic field to remove reaction impurities, and then the materials were dissolved in high-purity water and stored at 4°C.

[0025] 3) Take 5ml of the hyaluronic acid-modified Fe obtained in step 2) 3 o 4 For nanomaterials, use a magnet to suck out the nanomaterials, discard the supernatant, redissolve th...

Embodiment 2

[0029] A dual-target modified Fe with good biocompatibility 3 o 4 The preparation method of nanometer material, the steps are as follows:

[0030] 1) In a 100mL three-neck round bottom flask, 0.25g FeCl 3 ·6H 2 O and 0.092 g FeCl 2 4H 2 O dissolved in 20mLH 2 O, dissolved by mechanical stirring, and protected by nitrogen gas. After 15min, adding 5mL mass concentration to the above solution was 27%NH 4 OH, then add 7.5mL hyaluronic acid (molecular weight 3k Da, 40mg / mL), and continue the reaction at room temperature for 30min.

[0031] 2) the obtained hyaluronic acid modified Fe 3 o 4 The nanomaterials were washed four times with high-purity water using an external magnetic field to remove reaction impurities, and then the materials were dissolved in high-purity water and stored at 4°C.

[0032] 3) Take 5ml of the hyaluronic acid-modified Fe obtained in step 2) 3 o 4 For nanomaterials, use a magnet to suck out the nanomaterials, discard the supernatant, redissolve t...

Embodiment 3

[0036] A dual-target modified Fe with good biocompatibility 3 o 4 The preparation method of nanometer material, the steps are as follows:

[0037] 1) In a 100mL three-neck round bottom flask, 1g FeCl 3 ·6H 2 O and 0.368 g FeCl 2 4H 2 O dissolved in 20mLH 2 O, dissolved by mechanical stirring, and protected by nitrogen gas. After 15min, add 10mL mass concentration to the above solution and be 27%NH 4 OH, then add 10mL hyaluronic acid (molecular weight 4k Da, 40mg / mL), and continue the reaction at room temperature for 30min.

[0038] 2) the obtained hyaluronic acid modified Fe 3 o 4 The nanomaterials were washed four times with high-purity water using an external magnetic field to remove reaction impurities, and then the materials were dissolved in high-purity water and stored at 4°C.

[0039] 3) Take 5ml of the hyaluronic acid-modified Fe obtained in step 2) 3 o 4 For nanomaterials, use a magnet to suck out the nanomaterials, discard the supernatant, redissolve the ...

PUM

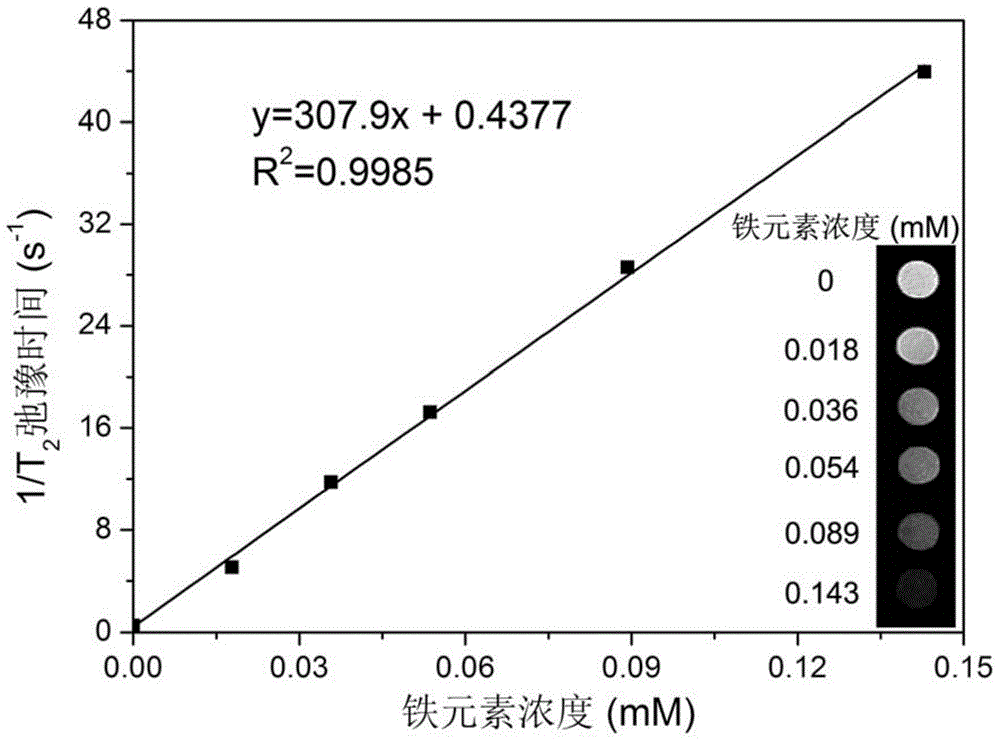

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Transverse relaxation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com