Preparation method for thin titanium dioxide layer of perovskite cell

A perovskite cell and titanium dioxide technology, applied in the field of solar cells, can solve the problems of low photocatalyst efficiency and narrow photoresponse range, and achieve the effect of low material price, simple manufacturing process, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

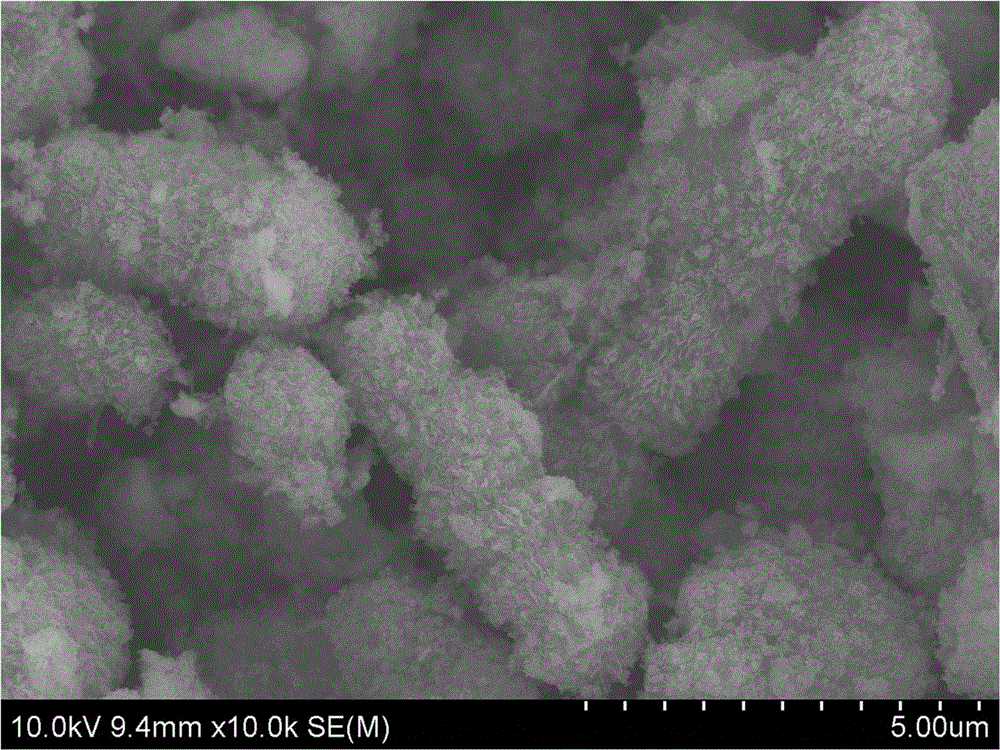

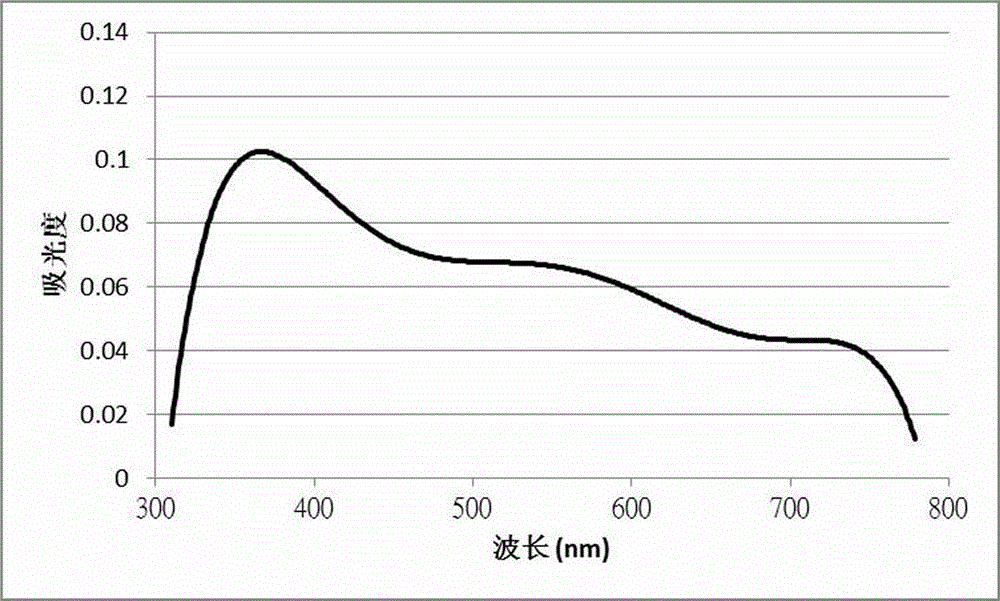

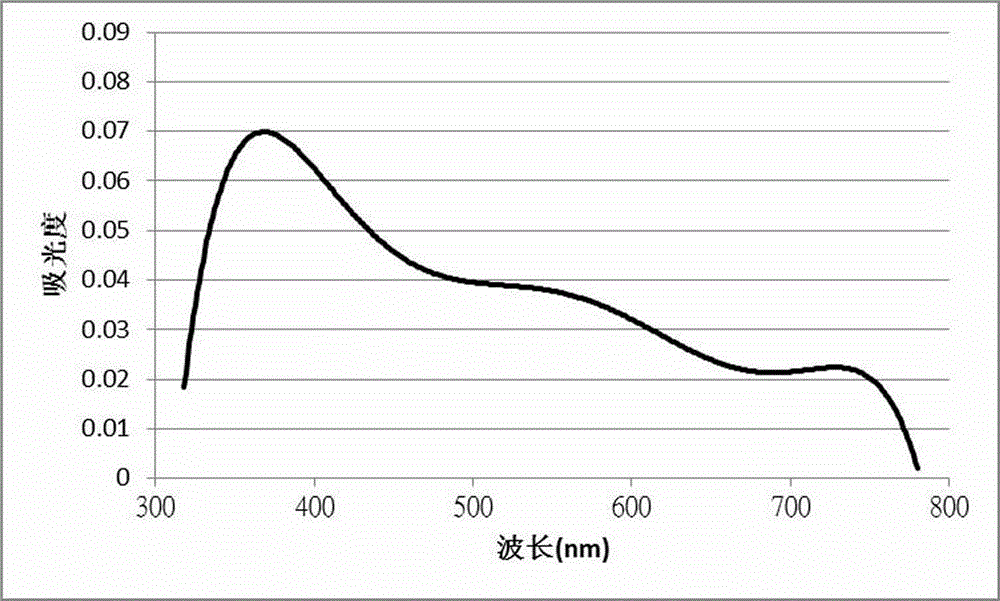

Image

Examples

Embodiment 1

[0029] Each coating preparation method:

[0030]

[0031] Preparation:

[0032] (1) Add deionized water, concentrated hydrochloric acid and tetra-n-butyl titanate into a beaker in sequence, stir until a uniform solution is obtained, and conduct a hydrothermal reaction at 180°C for 24 hours to prepare titanium dioxide colloid.

[0033] (2) PbI 2 Slowly add the solid into the DMF (N-N dimethylformamide) solution to prepare a 0.1M solution, stir evenly at 60-80°C, filter the solution and take the filtrate for storage.

[0034] (3) Change CH 3 NH 3 Add the I solid to the isopropanol solution to prepare a 10 mg / mL homogeneous solution.

[0035] (4) According to the parameters in the chart, spin-coat each coating with different thicknesses in sequence to prepare perovskite electrodes.

Embodiment 2

[0037] Each coating preparation method and thickness:

[0038]

[0039] Preparation:

[0040] (1) Add deionized water, concentrated hydrochloric acid and tetra-n-butyl titanate into a beaker in sequence, stir until a uniform solution is obtained, and conduct a hydrothermal reaction at 180°C for 24 hours to prepare titanium dioxide colloid.

[0041] (2) PbI 2 Slowly add the solid into the DMF (N-N dimethylformamide) solution to prepare a 0.1M solution, stir evenly at 60-80°C, filter the solution and take the filtrate for storage.

[0042] (3) Change CH 3 NH 3 Add the I solid to the isopropanol solution to prepare a 10 mg / mL homogeneous solution.

[0043] (4) According to the parameters in the chart, spin-coat each coating with different thicknesses in sequence to prepare perovskite electrodes.

Embodiment 3

[0045] Each coating preparation method and thickness:

[0046]

[0047] Preparation:

[0048] (1) Add deionized water, concentrated hydrochloric acid and tetra-n-butyl titanate into a beaker in sequence, stir until a uniform solution is obtained, and conduct a hydrothermal reaction at 180°C for 24 hours to prepare titanium dioxide colloid.

[0049] (2) PbI 2 Slowly add the solid into the DMF (N-N dimethylformamide) solution to prepare a 0.1M solution, stir evenly at 60-80°C, filter the solution and take the filtrate for storage.

[0050] (3) Change CH 3 NH 3 Add the I solid to the isopropanol solution to prepare a 10 mg / mL homogeneous solution.

[0051] (4) According to the parameters in the chart, spin-coat each coating with different thicknesses in sequence to prepare perovskite electrodes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com