A kind of reuse method of organic waste gas containing ethylene oxide

A technology of organic waste gas and ethylene oxide, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as complex treatment processes, unsafe treatment methods, and difficult treatment of process wastewater, and achieve short process flow , Reduce the cost of environmental protection treatment, easy industrialization and continuous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

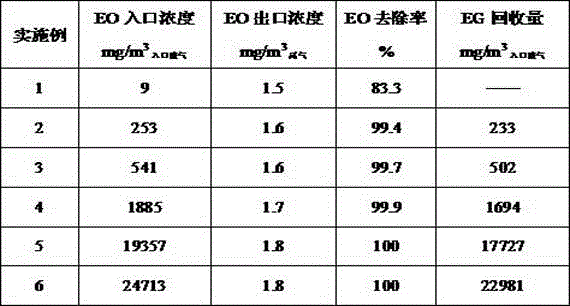

Embodiment 1

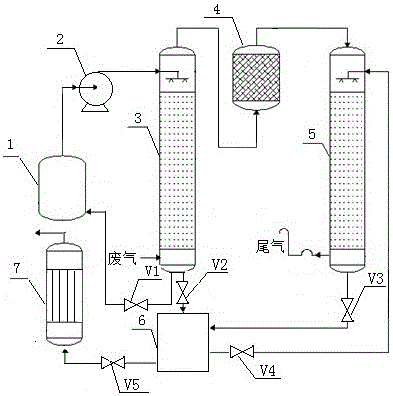

[0032] Under normal temperature and pressure, the 0.5% dilute H stored in the acid storage tank 1 2 SO 4The acid and alkali resistant pump 2 is added from the top of the hydrolysis tower 3, the organic waste gas containing ethylene oxide is passed into the tower from the bottom of the hydrolysis tower 3, and the one-way stop valve V1 is opened to make the dilute sulfuric acid solution in the acid storage An internal circulation system is formed between the tank, the acid and alkali resistant pump and the hydrolysis tower. Organic waste gas containing ethylene oxide and dilute H 2 SO 4 After sufficient contact, in this process, ethylene oxide is diluted with H 2 SO 4 Catalysis, a hydration reaction occurs to generate ethylene glycol, and most of the ethylene oxide in the organic waste gas is diluted with H 2 SO 4 The absorption is brought into the liquid phase. After the ethylene glycol aqueous solution in the absorption liquid reaches 20±1%, the one-way stop valve V1 is ...

Embodiment 2

[0036] Under normal temperature and normal pressure, the concentration of dilute sulfuric acid in the acid storage tank 1 is 0.5%. The high-performance catalyst in reactor 4 is selected from honeycomb structure Al with supported Pt and Pd 2 o 3 High-performance catalyst, the reaction temperature is 150°C.

[0037] In the above operation process, the gas volume flow rate of the organic waste gas containing ethylene oxide that passes into the hydrolysis tower 3 is different from the dilute H that passes into the hydrolysis tower 3. 2 SO 4 The ratio of liquid to volume flow of the solution is controlled at 5:1.

[0038] All the other operating conditions are the same as in Example 1.

Embodiment 3

[0040] At normal temperature and pressure, the dilute H in the acid storage tank 1 2 SO 4 The concentration is 1.0%. The high-performance catalyst in reactor 4 is selected from honeycomb structure Al with Pt loading 2 o 3 High-performance catalyst, the reaction temperature is 150°C.

[0041] In the above operation process, the gas volume flow rate of the organic waste gas containing ethylene oxide that passes into the hydrolysis tower 3 is different from the dilute H that passes into the hydrolysis tower 3. 2 SO 4 The ratio of liquid to volume flow of the solution is controlled at 5:1.

[0042] All the other operating conditions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com