Alginate lyase SHA-I gene and expression vector thereof

An alginate lyase and gene technology, which is applied in the directions of lyase, genetic engineering, plant genetic improvement, etc., can solve problems such as difficulty in meeting practical application requirements and low enzyme yield, and achieve easy industrial production, solve the problem of low enzyme yield, Easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

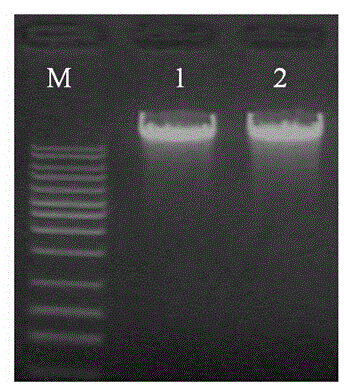

[0038] Example 1: Marinicatena alginatilytica Preparation and Detection of SH-52 Genomic DNA

[0039] used in the present invention Marinicatena alginatilytica SH-52 is the strain screened by our laboratory, Marinicatena alginatilytica The preparation of SH-52 genomic DNA adopts the extraction method of common bacterial genome, and the specific content is as follows: Take 2 mL of overnight culture liquid at 4 ° C, centrifuge at 4000 rpm for 2 min, discard the supernatant, and collect the bacteria; add 100 μl Solution I suspension bacteria, 30 μl 10% SDS and 1μl 20mg / ml proteinase K, mix well, incubate at 37°C for 1h; add 100μl 15mol / L NaCl, mix well; add 20μl CTAB / NaCl solution (CTAB 10%, NaCl 0.7mol / L), mix well, 65°C, 10min; add an equal volume of phenol / chloroform / isoamyl alcohol (25:24:1) to mix, centrifuge at 12000rpm for 5min; take the supernatant, add 2 times the volume of absolute ethanol, 0.1 times the volume of 3mol / L NaOAC, - Place at 20°C for 30 minutes; ce...

Embodiment 2

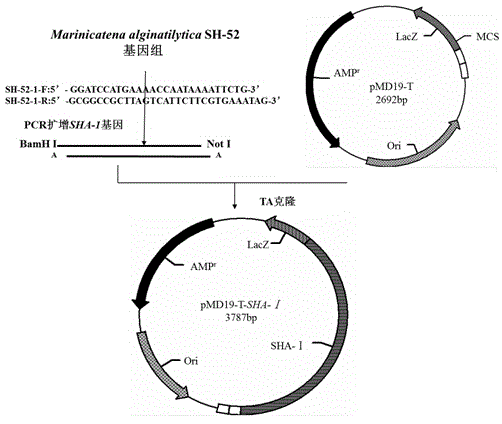

[0040] Example 2: Amplification and TA Cloning of Alginate Lyase SHA-I Gene

[0041] Amplification and cloning of alginate lyase SHA-I gene figure 2 As shown, first find out from the whole genome sequencing results SHA-I The full-length gene sequence, and design a pair of specific primers, the sequence is as follows:

[0042] SHA-I-F: GGATCC ATGAAAACCAATAAAATTCTG

[0043] SHA-I-R: GCGGCCGC TTAGTCATTCTTCGTGAAATAG

[0044] The 5' end primer has the GGATCC characteristic sequence, and thus forms the BamH I restriction site; the 3' end adds the GCGGCCGC characteristic sequence to form the Not I restriction site.

[0045] Add 10 ng of Marinicatena alginatilytica SH-52 genomic DNA was used as a template, and 50ng of specific primers SHA-I-F and SHA-I-R, 2.5ul dNTP (10mM), 2.5ul of Pfu reaction buffer and 0.5ul of pfu (5U / ul) polymerase (Beijing Quanshijin Biotechnology Co., Ltd.), add double distilled water to make the final volume 25ul. Heated at 94°C for 3 minutes...

Embodiment 3

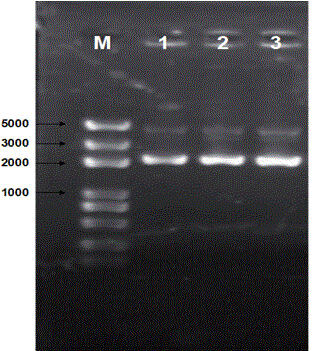

[0046] Example 3: Prokaryotic expression vector pGEX-4T-1- SHA-I build

[0047] pGEX-4T-1- SHA-I A build strategy such as Figure 6 As shown, the purified prokaryotic expression vectors pGEX-4T-1 (purchased from GE Healthcare) and pMD19-T- SHA-I , separated the cleaved vector and insert fragments by agarose gel electrophoresis, and recovered the vector fragments pGEX-4T-1 (4.9kb) and pMD19-T- SHA-I produced by cutting SHA-I The DNA fragment of the gene (about 1.1kb), and then use the ligase kit of TaKaRa to connect the pGEX-4T-1 vector fragment and SHA-I The DNA fragment of the gene produces the prokaryotic expression vector pGEX-4T-1- SHA-I . Use the ligation reaction mixture to transform high-efficiency E. coli competent cells Trans1-T1 (Beijing Quanshijin Biotechnology Co., Ltd.), and spread the transformed E. coli on a plate with ampicillin (Amp, 100ug / ml) , cultivated overnight at 37°C, screened Amp-resistant recombinant colonies, and extracted plasmids from Amp-re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com