Genetic recombinant method of pseudomonas aeruginosa for high-yield producing rhamnolipid

A technology of Pseudomonas aeruginosa and rhamnolipid, which is applied in the field of bioengineering, can solve the problems of unstable production performance of strains, easy reversion of physical and chemical mutagenesis, etc., and achieve the effect of reducing production costs and promoting high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with specific implementation.

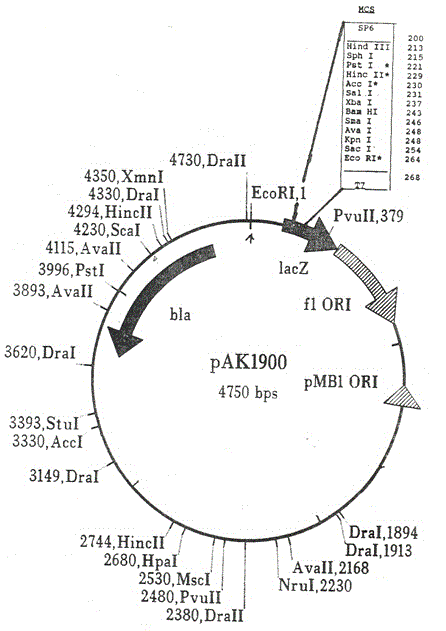

[0033] Construction of rhamnolipid-producing Pseudomonas aeruginosa engineered bacteria

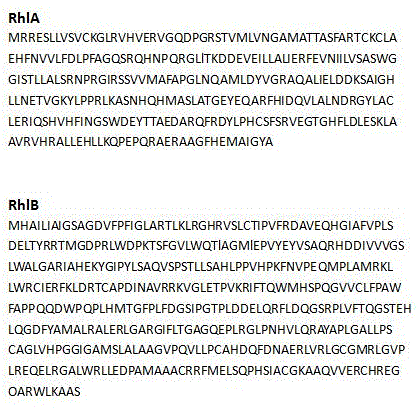

[0034] 1) Primer design for PCR amplification of RhlAB gene

[0035] Primers were designed according to literature reports and the gene sequence of rhamnolipid synthase RhlAB was searched on NCBI for amplifying the RhlAB gene (including the rhamnosyltransferase's own promoter and structural genes RhlA, RhlB).

[0036] WA: sense: gaatcgaattcatgcggccgaaagtctgt EcoRI 30nt

[0037] WB: anti-sense: cggtaagctttcaggacgcagccttcagcc HindIII 30nt

[0038] 2) PCR amplification of the target gene

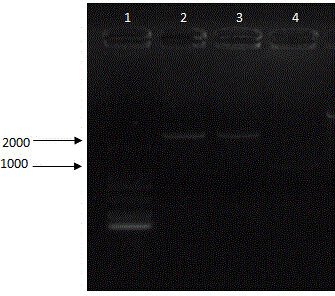

[0039] Using the chromosome of wild-type rhamnolipid-producing Pseudomonas aeruginosa (preservation number: CCTCC NO: M2011287) as a template, PCR reaction was performed. After the reaction, the PCR product was subjected to agarose gel electrophoresis, and the kit was used for The target gene w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com