Azobenzene-contained microcapsule-type liquid crystal and application thereof in light-controlled liquid-crystal falsification-resistant ink

An anti-counterfeiting ink, azobenzene technology, applied in the field of ink, can solve the problems of complex operation method, short service life, poor stability of microcapsule ink, etc., and achieve the effect of wide application prospect, long service life and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

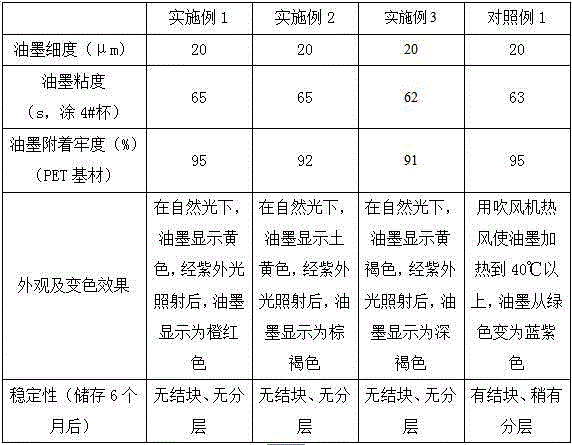

Examples

Embodiment 1

[0064] (1) Preparation of mesogen

[0065] a. Take 2.55g of 20% dilute hydrochloric acid and add it to the reaction flask, and cool it in an ice-water bath; weigh 3.46g of p-aminobenzenesulfonic acid and 1.38g of sodium nitrite, add an appropriate amount of water to make a paste, and then make the paste The solid was added into a reaction flask filled with hydrochloric acid, and after stirring for 20 minutes, a diazonium salt solution was obtained. Add 1.88g of phenol, 50mL of water and 0.8g of sodium hydroxide into another reaction flask, stir to dissolve, place in an ice-water bath to control the temperature at 0-5°C, add the diazonium salt solution prepared above, and stir for 10min-15min. After the reaction, dilute hydrochloric acid was added to adjust the pH of the solution to 5-6, filtered, precipitated, recrystallized with ethanol, and vacuum-dried at 50°C to obtain an earthy red powder.

[0066] b. 2.54g of the above earth red powder, 24.4g of 1,6-dibromohexane, 10g o...

Embodiment 2

[0083] (1) Preparation of mesogen

[0084] a. Take 2.55g of 20% dilute hydrochloric acid and add it into the reaction flask, and cool it in an ice-water bath; weigh 3.46g of p-aminobenzenesulfonic acid and 1.38g of sodium nitrite, add an appropriate amount of water to make a paste, and then make the paste The substance was added into a reaction flask filled with hydrochloric acid, and after stirring for 20 minutes, a diazonium salt solution was obtained. Add 1.88g of phenol, 50mL of water and 0.8g of sodium hydroxide into another reaction flask, stir to dissolve, place in an ice-water bath to control the temperature at 0-5°C, add the diazonium salt solution prepared above, and stir for 10min-15min. After the reaction, dilute hydrochloric acid was added to adjust the pH of the solution to 5-6, filtered, precipitated, recrystallized with ethanol, and vacuum-dried at 50°C to obtain an earthy red powder.

[0085] b. 2.54g of the above earth red powder, 24.4g of 1,6-dibromohexane,...

Embodiment 3

[0103] (1) Preparation of mesogen

[0104] a. Add 2.76g of p-hydroxybenzoic acid, 0.8g of sodium hydroxide, and 50mL of deionized water into a three-necked flask, dissolve them under stirring, raise the temperature to 78-82°C, add 0.1g of KI to catalyze the reaction, and add dropwise 6-chloro-1- Hexanol 5mL, reaction 20h. Dilute with water, add hydrochloric acid dropwise to cool and precipitate a white milky substance, adjust the pH value to 5 to obtain a large amount of white precipitate, filter with suction, recrystallize the filter cake with deionized water for 3 times, and dry at 100°C to obtain a white powder.

[0105] b. Add 3.64g of the above white powder crystals, 50mL of benzene, and 20mL of acrylic acid into a three-neck flask, heat to 87-90°C with stirring, and reflux for 15h. Most of the benzene was evaporated with a rotary evaporator, the solid was precipitated in an ice bath, filtered with suction, the filter cake was recrystallized twice with isopropanol, and v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com