Large-specific surface area graphite-phase carbonitride photocatalyst and application thereof in photocatalytic degradation reaction of TCP and photocatalysis reaction for hydrogen production

A technology of photocatalytic carbon nitride and large specific surface area, which is applied in the direction of physical/chemical process catalysts, hydrogen production, chemical instruments and methods, etc., and can solve problems such as unsatisfactory photocatalytic performance, small specific surface area, and complicated preparation , to achieve superior catalytic activity and stability, large specific surface area, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

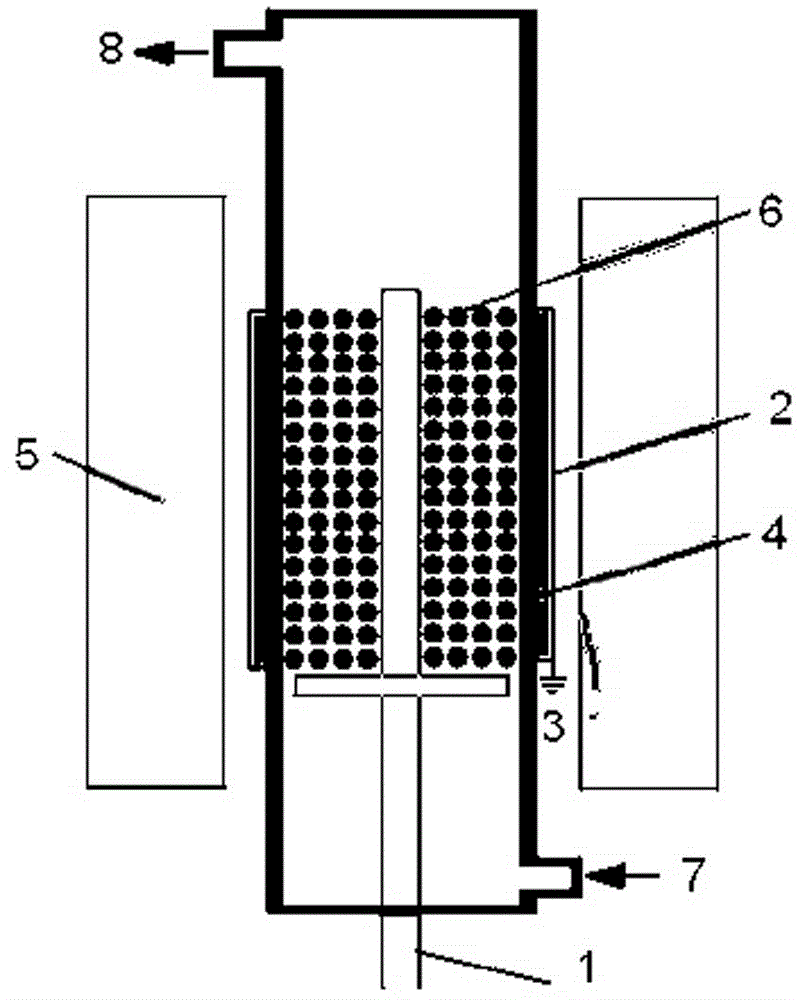

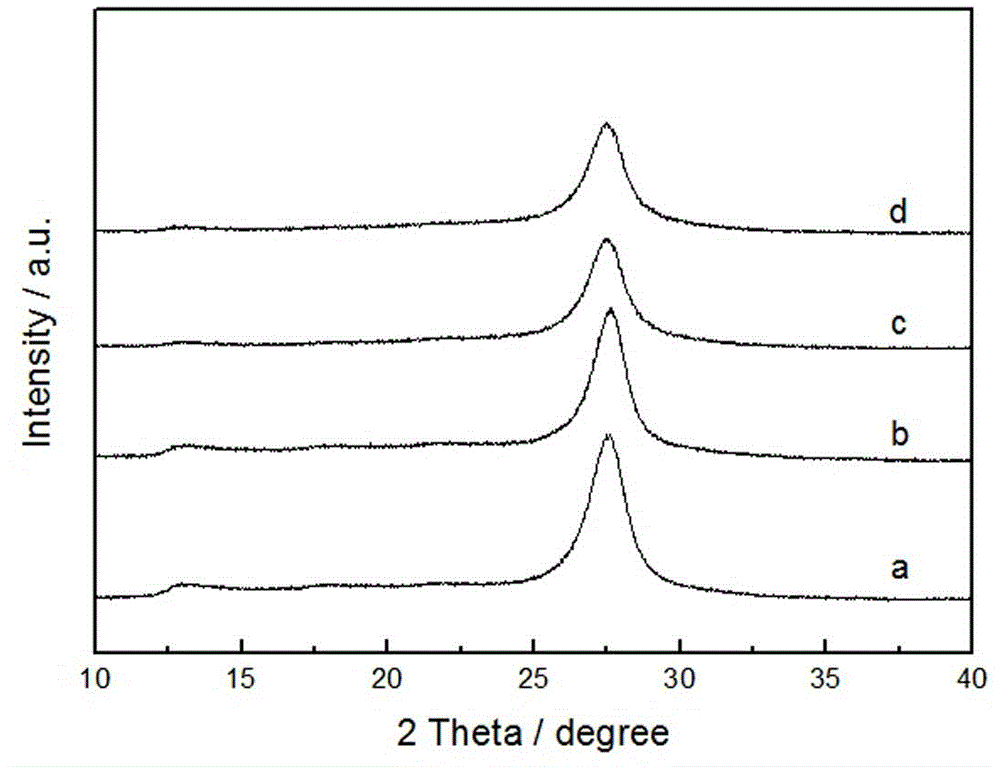

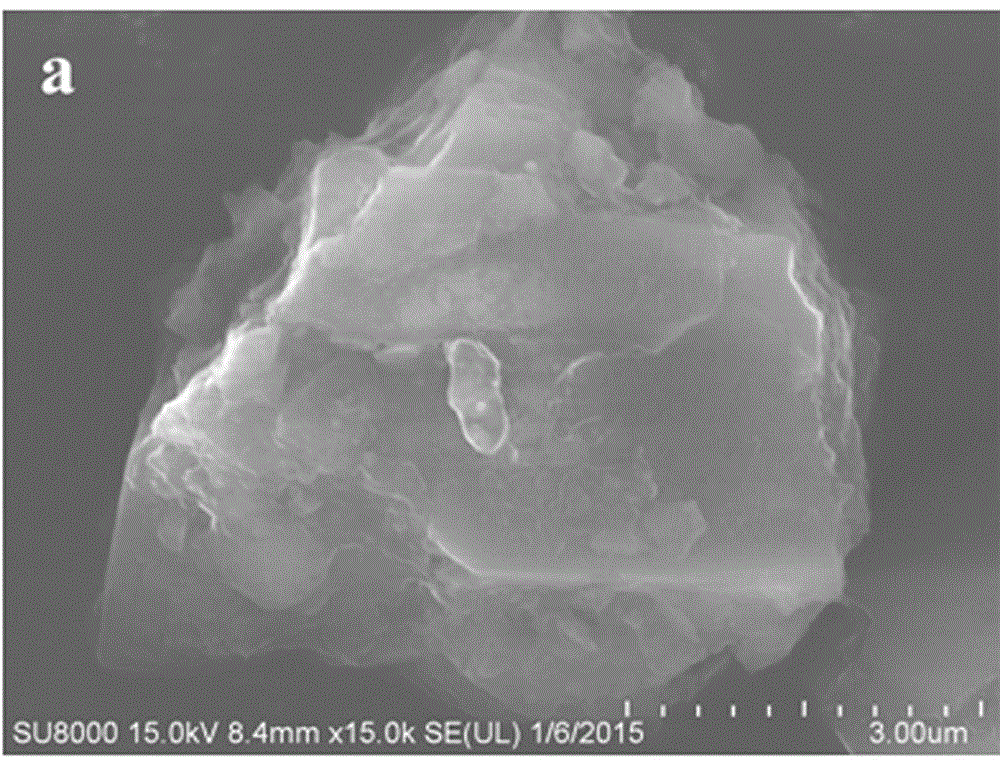

[0027] Using nitrogen as the discharge gas, the catalyst precursor melamine was discharged by using a dielectric barrier discharge plasma generator. The dielectric barrier discharge plasma generator consists of a quartz tube and two electrodes. A stainless steel wire with a diameter of 2.5 mm is used as a high-voltage electrode, which is installed at the axis of the quartz tube, and one end is connected to an AC power supply. The aluminum foil tightly wound outside the quartz tube is used as the ground electrode and connected to the ground. The structure diagram of the dielectric barrier discharge plasma generator is as follows: figure 1 Shown or use the existing commercially available plasma generator. see figure 1As shown, 1 is the high-voltage electrode; 2 is the ground electrode; 3 is the ground; 4 is the quartz tube; 5 is the heat insulation layer; 6 is the catalyst precursor bed; 7 is the gas inlet; 8 is the gas outlet. Put 0.5 g of melamine into the quartz tube, adj...

Embodiment 2

[0029] In Example 1, the catalyst precursor was changed to dicyandiamide, the input voltage was changed to 80 V, and other steps and conditions remained unchanged, a graphitic carbon nitride photocatalyst with a large specific surface area was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com