Gold nano material adopting porous tubular hollow structure and preparation method of gold nano material

A technology of tubular structure and gold nano, which is applied in the field of gold nano material with porous tubular hollow structure and its preparation. Achieve the effect of poor repeatability, convenient operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of silver nanowires: Add 10 milliliters of anhydrous ethylene glycol into a 50 milliliter three-neck flask, heat the oil bath to 155°C and keep the temperature constant for 1 hour, then mix the prepared 0.1 mol / liter silver nitrate ethylene glycol solution and 0.15 mol / liter Each 6 ml of polyvinylpyrrolidone ethylene glycol solution was added dropwise to the above-mentioned three-necked bottle at a rate of 0.45 ml / min at the same time, and then kept at the temperature for 1 hour after dripping, and then centrifuged to obtain a diameter of 80-110 nanometers and a length of 1-20 microns. of silver nanowires.

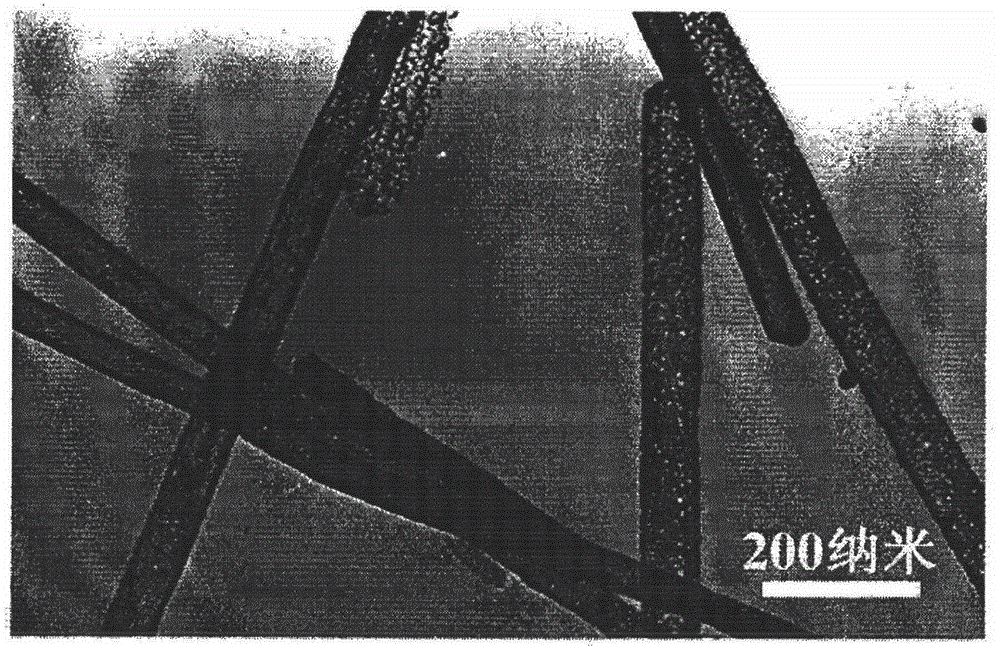

[0032]Preparation of gold nanomaterials with porous tubular hollow structure: disperse the obtained silver nanowires in 0.1 mol / liter cetyltrimethylammonium bromide aqueous solution, then add 0.04 mol / liter ascorbic acid aqueous solution as reducing agent, at 500 rpm Stir evenly at a stirring speed of 1 / min, then add 2 ml of 1 mmol / L chloroauric acid aqu...

Embodiment 2

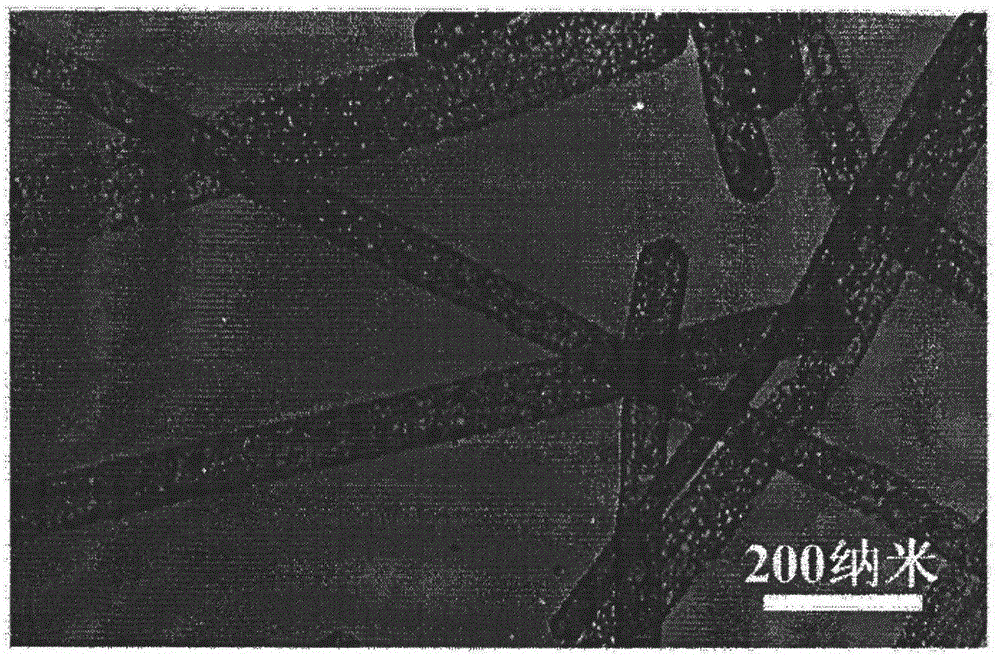

[0033] Embodiment 2: Similar to the process of Example 1, but when preparing the gold nanomaterial of porous tubular hollow structure, the consumption of 1 mmol / liter of chloroauric acid aqueous solution is reduced to 1 milliliter, and the stirring reaction time is reduced to 15 minutes, and obtains Gold-silver composite core-shell nanostructure with thin shell. After washing with methanol and ultra-pure water, place it in 1 ml of concentrated nitric acid for corrosion reaction for about 15 minutes, then centrifuge to obtain a gold nanomaterial with a porous tubular hollow structure with relatively obvious pores. figure 2 It is a transmission electron microscope image of a gold nanomaterial with a porous tubular hollow structure, by figure 2 It can be seen that the pore distribution is already obvious, but because the amount of chloroauric acid is less, the tube wall is thinner.

Embodiment 3

[0034] Embodiment 3: Similar to the process of Example 1, but when preparing the gold nanomaterial of porous tubular hollow structure, the consumption of 1 mmol / L aqueous auric acid chloride solution was reduced to 0.5 milliliters, and the stirring reaction time was shortened to 10 minutes to obtain Gold-silver composite core-shell nanostructure with relatively thinner gold shell. Corroded with 1 ml of concentrated nitric acid and centrifuged to obtain a porous tubular hollow structure gold nanomaterial with large porosity and pore diameter. image 3 It is a transmission electron microscope image of a gold nanomaterial with a porous tubular hollow structure, by image 3 It can be seen that the walls are thinner and the pores are larger.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com