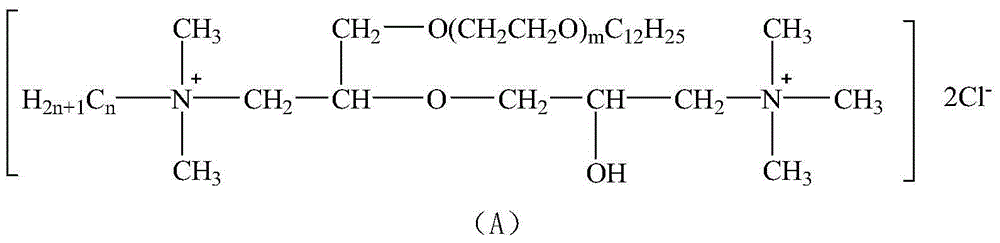

Dication asphalt emulsifier containing ethoxy as well as preparation method and application of dication asphalt emulsifier

A technology of asphalt emulsifier and dication, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of reducing the stability of emulsified asphalt, achieve the effects of reducing the demulsification speed, increasing the number of charge points, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 (preparation and structural analysis of the dicationic asphalt emulsifier containing ethoxy group)

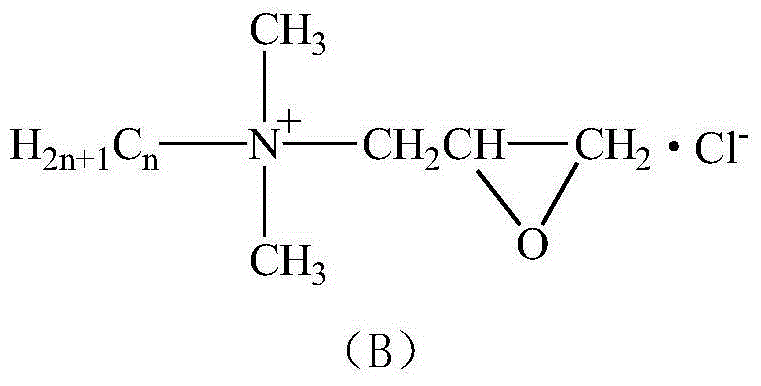

[0030] One, the preparation of intermediate B:

[0031] 2.97g (0.01mol) of octadecyldimethyl tertiary amine and 1.11g (0.012mol) of epichlorohydrin were dissolved in absolute ethanol, and stirred with magnetic force at 55°C for 8 hours, cooled to room temperature and distilled under reduced pressure. After washing with acetone, suction filtration, and vacuum drying at 40°C, intermediate B was obtained with a yield of 87.3%.

[0032] Two, the preparation of intermediate C:

[0033] 11.64g (0.02mol) fatty alcohol polyoxyethylene ether (9) is dissolved in n-hexane, add 0.322g (0.001mol) tetrabutylammonium bromide, add 0.96g (0.024mol) sodium hydroxide, stir to make it dissolve After 30 minutes, add the intermediate B obtained above, stir the reaction at 60°C for 10 hours, cool to room temperature, distill under reduced pressure, wash with ethyl acetate and ac...

Embodiment 2

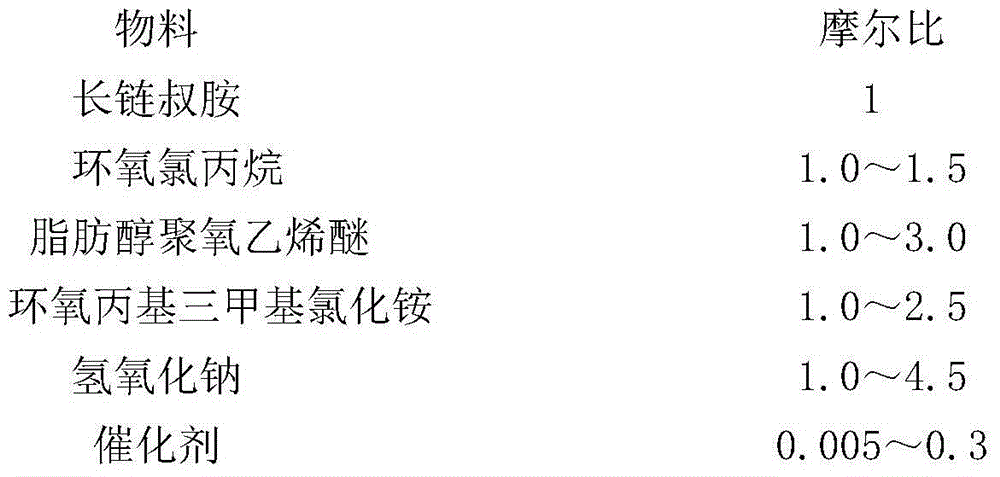

[0049] 1. Preparation of ethoxy-containing dicationic asphalt emulsifier:

[0050] 14.85g (0.05mol) of octadecyldimethyl tertiary amine and 5.55g (0.06mol) of epichlorohydrin were dissolved in absolute ethanol, and stirred with magnetic force at 55°C for 8 hours, cooled to room temperature and distilled under reduced pressure. Intermediate B is obtained.

[0051] 58.20g (0.10mol) fatty alcohol polyoxyethylene ether (9) is dissolved in n-hexane, add 1.61g (0.005mol) tetrabutylammonium bromide, add 4.80g (0.12mol) sodium hydroxide, stir to make it dissolve After 30 minutes, the above-mentioned intermediate B was added, and the reaction was carried out under magnetic stirring at 60° C. for 10 hours. After cooling to room temperature, the reaction was distilled under reduced pressure to obtain intermediate C.

[0052] Dissolve the above intermediate C in n-hexane, add 0.81g (0.0025mol) tetrabutylammonium bromide, add 3.0g (0.075mol) sodium hydroxide, stir to dissolve, add 15.15g ...

Embodiment 3

[0058] 1. Preparation of ethoxy-containing dicationic asphalt emulsifier:

[0059] Except that 58.20g fatty alcohol polyoxyethylene ether (9) was replaced with 49.40g fatty alcohol polyoxyethylene ether (7), others were the same as in Example 2. The obtained asphalt emulsifier is used for future use.

[0060] 2. Preparation of emulsified asphalt:

[0061] According to the method of Example 2, the emulsifier obtained above was used to emulsify asphalt. The data of various performance tests are: the emulsified asphalt is cationic, can be stored stably for 7 days, the evaporation residue is 61.2%, and the residue on the sieve is 0.05%. The time is 85 minutes. It meets the requirements of "Technical Specifications for Highway Asphalt Construction".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com