A solid phase synthesis al 3+ ,cu 2+ Doped cubic bismuth fluoride lithium ion battery positive electrode material and preparation method thereof

A lithium-ion battery and cubic structure technology, which is applied in battery electrodes, secondary batteries, structural parts, etc., can solve the problems that the electron transport characteristics are greatly affected, the process conditions are harsh, and the content of by-products is too high to be used as positive electrode materials. , to achieve the effect of improving capacity cycle stability, avoiding side reaction products, and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

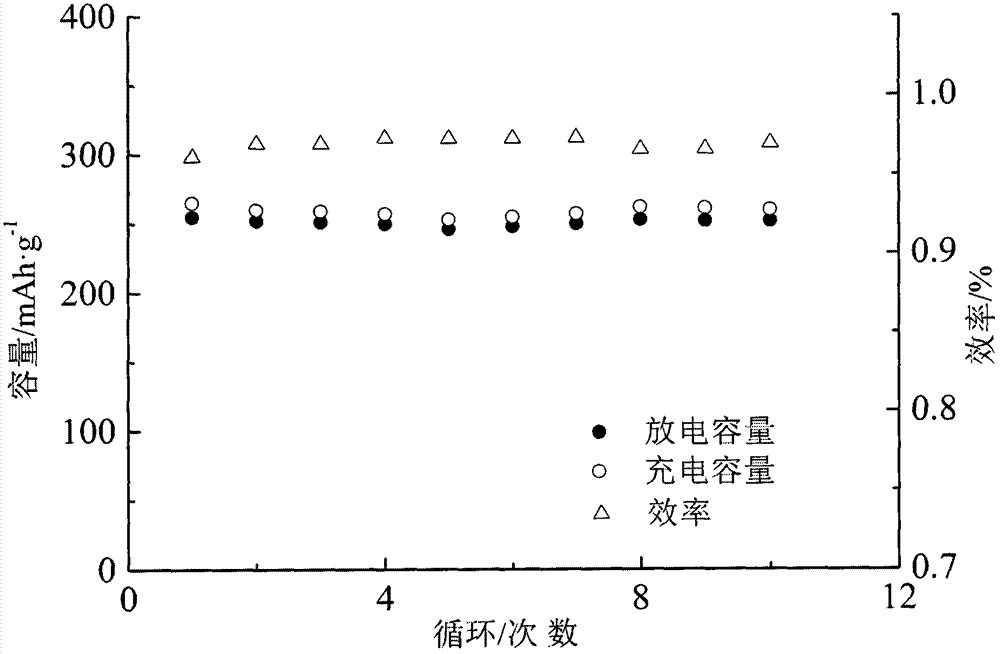

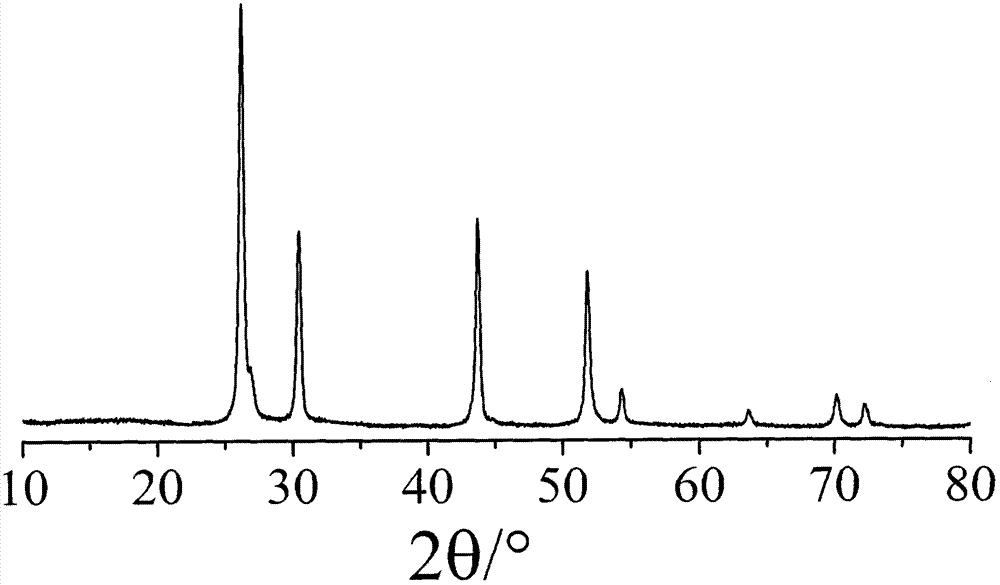

Embodiment 1

[0021] Embodiment 1: the perfluorinated aluminum nitrate nonahydrate of bismuth nitrate pentahydrate, the amount of bismuth nitrate pentahydrate substance 0.5%, copper sulfate pentahydrate pentahydrate of bismuth nitrate pentahydrate substance amount 0.5%, the perfluoro Heptanoic acid is mixed and put into a ball mill, the mass ratio of the ball mill and the material is 20:1, and ball milled at a speed of 200 rpm for 10 hours, this material is called material I; tetra-n-butylammonium fluoride, tetra-n-butyl ammonium Tween-60 with 0.5% of ammonium butyl ammonium fluoride and absolute ethanol with 2% of tetra-n-butyl ammonium fluoride are mixed and put into a ball mill. The mass ratio of the ball mill to the material is 20:1. Speed ball milling 10 hours, this material is called material II; Material I and material II are according to the ratio of the amount of bismuth salt in material I and the ratio of the amount of quaternary ammonium salt material in material II that is 1: 3...

Embodiment 2

[0022] Embodiment 2: 2, the 2-difluoro rings of bismuth chloride, bismuth chloride substance amount 1.0% aluminum chloride, bismuth chloride substance amount 1.0% copper nitrate trihydrate, bismuth chloride quality 1.0% Propylcarboxylic acid is put into ball mill after mixing, and the mass ratio of ball mill and material is 20: 1, with the speed ball milling of 300 rev / mins 15 hours, this material is called material I; Tetramethylammonium fluoride, tetramethylammonium 1.0% op-10 of the mass of ammonium fluoride and 3% absolute ethanol of the mass of tetramethylammonium fluoride are mixed and put into a ball mill. Ball milling 15 hours, this material is called material II; Material I and material II are according to the ratio of the amount of bismuth salt in material I and the ratio of the amount of quaternary ammonium salt material in material II that is 1: 3 and material I and material II The crystallization control agent methacrylic acid and neopentyl methacrylate block copo...

Embodiment 3

[0023] Embodiment 3: with bismuth chloride, bismuth chloride substance amount 2% aluminum sulfate octadecahydrate, bismuth chloride substance amount 1.8% copper acetate monohydrate, bismuth chloride quality 2% perfluoroglutaric acid Put into ball mill after mixing, the mass ratio of ball mill and material is 20: 1, ball mill with the speed of 390 revolutions / min for 20 hours, this material is called material I; Benzyl trimethyl ammonium fluoride, benzyl trimethyl 2% Span-80 of benzyltrimethylammonium fluoride quality and 4% dehydrated alcohol of benzyltrimethylammonium fluoride quality are mixed and put into a ball mill. The mass ratio of the ball mill and the material is 20:1, and the Speed ball milling per minute for 19 hours, this material is called material II; Material I and material II are according to the ratio of the amount of bismuth salt in material I and the ratio of quaternary ammonium salt material in material II to be 1: 3 ratio Put the crystallization control ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com