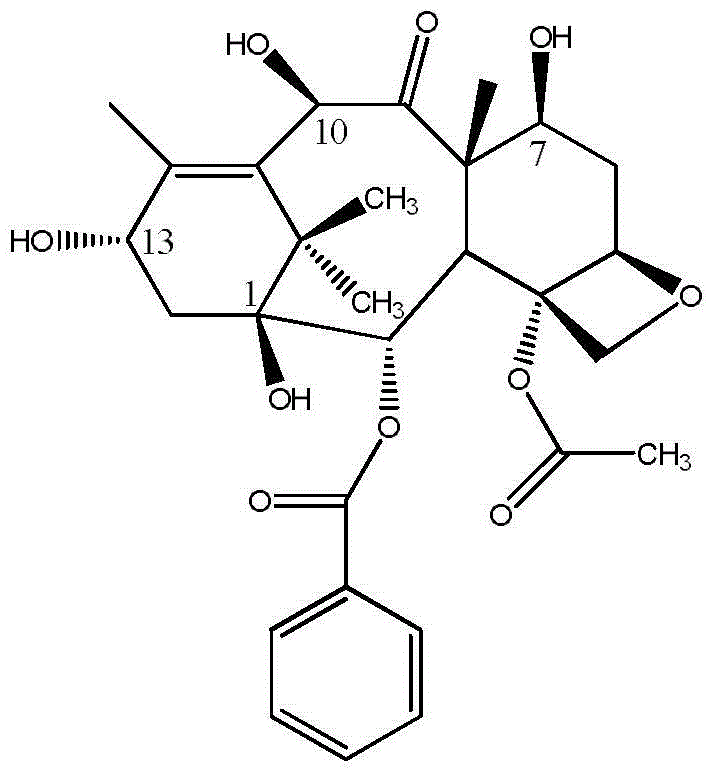

Method for separation and purification of 10-deacetylbaccatin III from branches and leaves of taxus chinensis

A technology for deacetylation of yew branches and leaves, applied in the field of high-purity 10-DAB III, can solve the problems of yield loss, time-consuming, large solvent consumption, etc., achieve low cost, reduce manpower, avoid column chromatography and heavy The effect of the crystallization operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Grind the yew branches and leaves into 100-mesh fine powder after drying, take 1 kg of fine powder and use the volume fraction of 80% ethanol aqueous solution to reflux extract for 5 hours, extract continuously for 3 times, and combine The filtrate was concentrated under reduced pressure to obtain 120 g of 10-DABIII extract.

[0024] (2) Dissolve the 10-DABIII extract in 300mL tetrahydrofuran and dry-load the sample, elute with ethyl acetate-petroleum ether (volume ratio ethyl acetate:petroleum ether=2:1), collect the elution containing 10-DABIII The liquid was removed, and the solvent was evaporated to obtain 1.85 g of 10-DABIII semi-finished product.

[0025] (3) Dissolve the above 10-DABIII semi-finished product in 20 mL of dichloromethane, add 0.20 g of imidazole, stir at room temperature for 30 minutes, let it stand, cool at 0°C, filter the resulting crystalline solid, and dry it in vacuum to obtain 10-DABIII and imidazole 1.08g of the crystalline complex.

...

Embodiment 2

[0028] (1) Grind the yew branches and leaves into 100-mesh fine powder after drying, take 10kg of powder and use the volume fraction of 80% ethanol aqueous solution to reflux extract for 5 hours, extract continuously for 3 times, and combine the filtrate , and concentrated under reduced pressure to obtain 1350 g of 10-DABIII extract.

[0029] (2) The 10-DABIII extract was dissolved in 3000mL THF, and then dry-loaded several times, eluted with ethyl acetate-cyclohexane (volume ratio ethyl acetate:cyclohexane = 2:1), and 10-DABIII was collected. -DABIII eluate, distill off the solvent to obtain 22.8g of 10-DABIII semi-finished product.

[0030] (3) Dissolve the above 10-DABIII semi-finished product in 200mL of dichloromethane, add 3.0g of imidazole, stir at room temperature for 30min, let stand, cool at 0°C, filter the resulting crystalline solid, and dry in vacuo to obtain 10-DABIII and imidazole The crystalline complex of 11.9g.

[0031] (4) The crystalline complex of 10-DAB...

Embodiment 3

[0033] (1) Grind the yew branches and leaves into 100-mesh fine powder after drying, take 5kg of powder and use the volume fraction of 80% ethanol aqueous solution to reflux extract for 5 hours, extract continuously for 3 times, and combine the filtrates , and concentrated under reduced pressure to obtain 680 g of 10-DABIII extract.

[0034] (2) Dissolve the 10-DABIII extract in 1200mL of dichloromethane, dry-load the sample several times, elute with ethyl acetate-petroleum ether (volume ratio ethyl acetate:petroleum ether=2:1), collect 10 -DABIII eluate, distill off the solvent to obtain 10.9g of 10-DABIII semi-finished product.

[0035] (3) After dissolving the above-mentioned 10-DABIII semi-finished product in 100mL of dichloromethane, add 2.0g of imidazole, stir at room temperature for 30min, let stand, cool at 0°C, filter the obtained crystalline solid, and dry in vacuum to obtain 10-DABIII and imidazole 5.8g of the crystalline complex.

[0036] (4) The crystalline comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com