Feruloyl-esterase-producing Bacillus licheniformis strain and application thereof

A technology of Bacillus licheniformis and ferulic acid esterase, which is applied in the field of microbial fermentation, can solve problems such as limiting effective degradation, and achieve the effects of short fermentation time, low requirements for carbon and nitrogen sources, and good genetic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

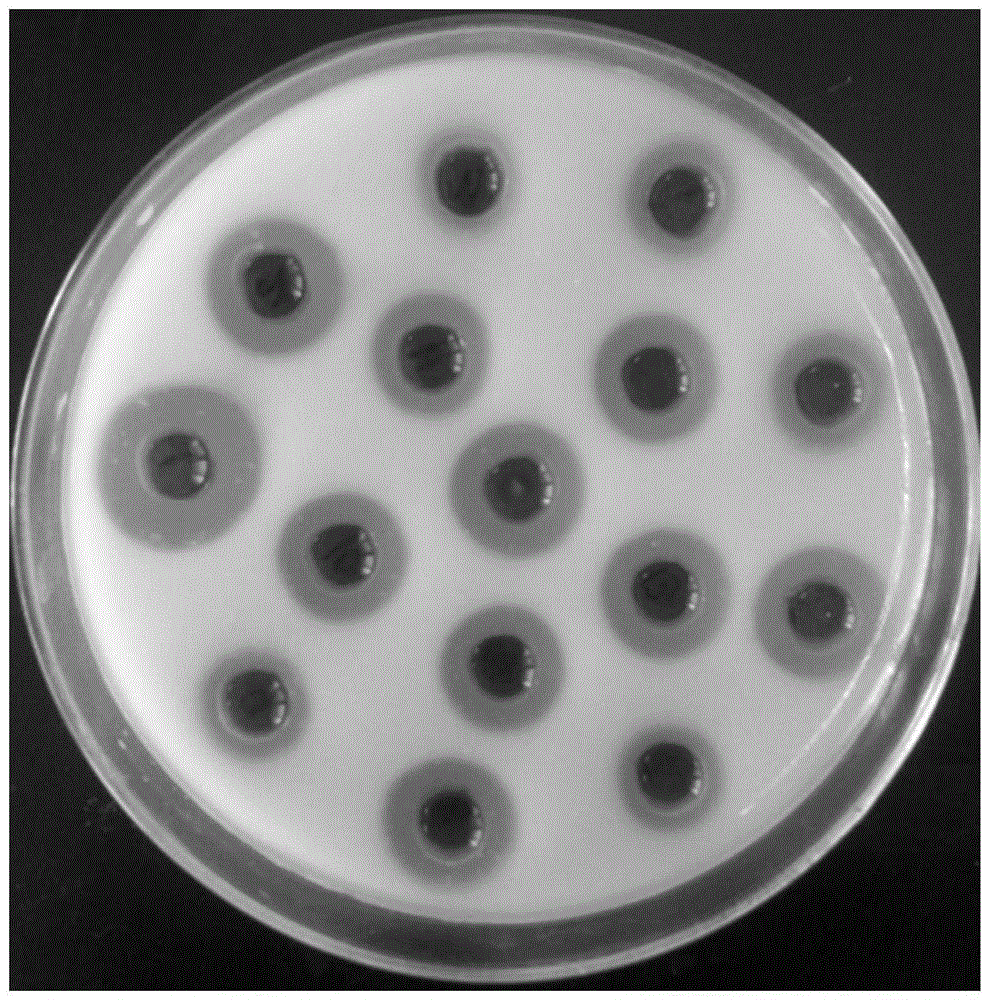

[0039] The screening method of bacillus licheniformis (Baclicus lincheniformis) DBM12, comprises the following steps:

[0040] Step 1, soil sample collection and processing

[0041] The soil samples were collected from livestock manure compost in the countryside of Yunlong District, Xuzhou City, Jiangsu Province, which was undergoing high-temperature fermentation. The collected soil samples were stored in sealed sterile plastic bags at room temperature, and the target strains were isolated within 1 week.

[0042] Take 5-10g of soil samples and put them into a conical flask filled with 20-40mL sterile water and small glass beads, put them on a shaker, rotate and shake at 120-160r / min for 20-30min, then place the conical flask at 70 Heat in a water bath at -80°C for 15-30 minutes, and shake once every 5 minutes during this period.

[0043] Step 2, enrichment culture

[0044] Take 1-2mL heat-treated soil samples in a Erlenmeyer flask filled with 30-50mL enrichment medium 1, an...

Embodiment 2

[0068] Example 2 Application of Bacillus licheniformis DBM12 to ferment and produce ferulic acid esterase and prepare ferulic acid

[0069] The Bacillus licheniformis DBM12 strain obtained by screening was fermented, and the fermentation medium formula was: 2 g of peptone, 0.5 g of glucose, 2 g of bran powder passed through a 60-mesh sieve, 1 g of bran powder passed through a 60-mesh sieve, 0.5 g of yeast extract, NaCl 0.4g, KH 2 PO 4 0.1g, MgSO 4 0.05g, distilled water 100ml, pH7.0-7.5. The fermentation conditions are as follows: a fermentation period of 2-3 days, a fermentation temperature of 35-40° C., an inoculum size of 4-10%, and a shaker rotation speed of 160-200 r / min.

[0070] After the fermentation, the fermentation broth was centrifuged at 8000r / min for 20min to remove the bacteria, and the residual bacteria and insoluble matter were removed by 0.22μm filter, and the filtrate was collected. According to the ammonium sulfate saturation of 75%, add ammonium sulf...

Embodiment 3

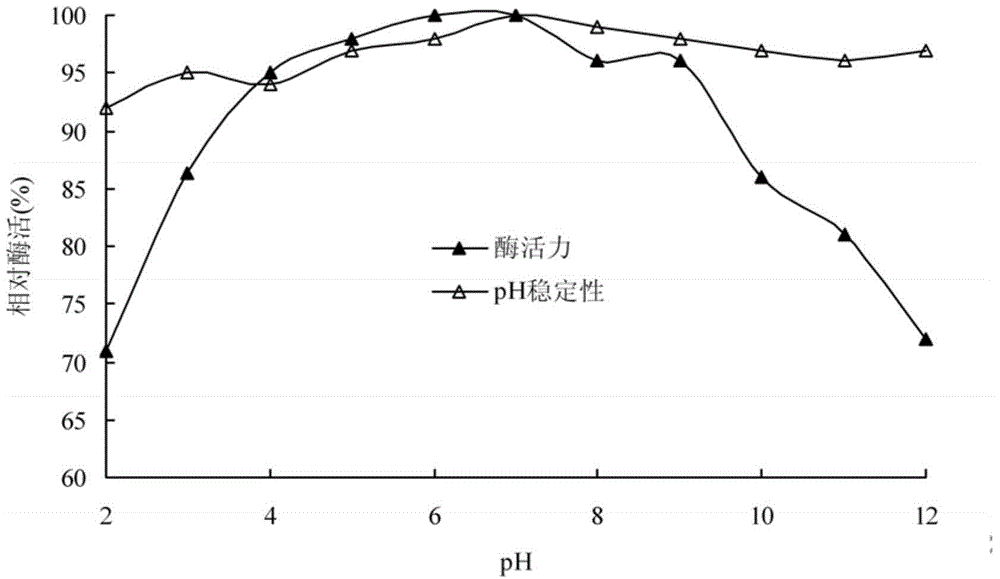

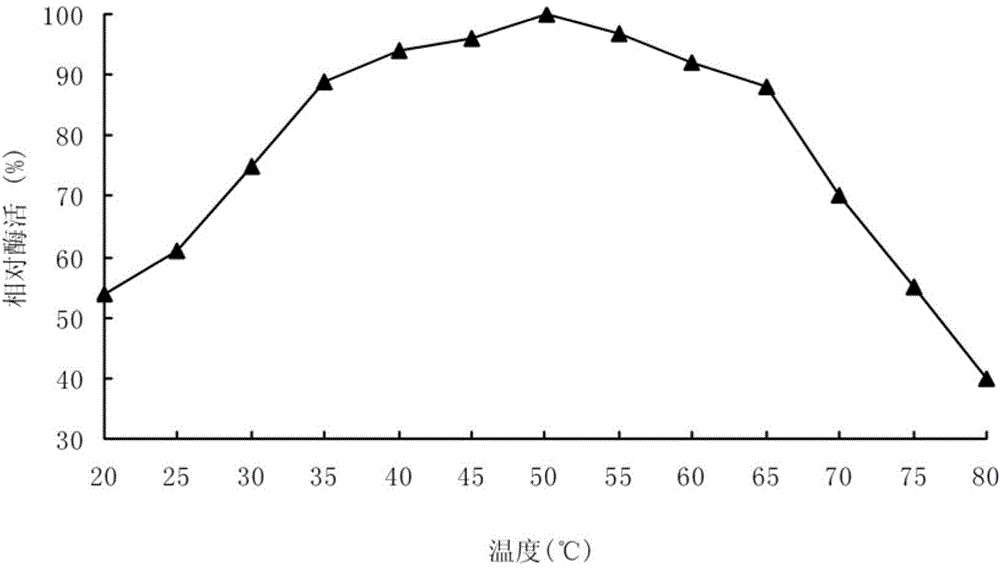

[0072] Enzyme activity and enzymatic characteristic determination of embodiment 3 ferulic acid esterase

[0073] In this embodiment, the fermented liquid obtained in Example 2 is used as a sample for determination.

[0074] 1. Determination of Ferulic Esterase Activity in Fermentation Broth

[0075] Add 0.5mL enzyme solution to a 2mL centrifuge tube, then add 0.5mL methyl ferulate solution, mix thoroughly, keep warm at 50°C for 20min, and then add 1mL glacial acetic acid with a volume fraction of 10% to terminate the reaction. The sample was centrifuged at 12000r / min for 10min, the supernatant was reserved, and after being properly diluted, the ferulic acid content in the sample was determined by high performance liquid chromatography (HPLC). The blank sample is boiled inactivated enzyme solution, and the treatment method is the same as above. The enzyme activity definition of ferulic acid esterase: under the conditions of 50°C and pH value of 6.5, the amount of enzyme neede...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com