Intermediate-infrared detector and preparation method thereof

An infrared detector and solution technology, applied in semiconductor/solid-state device manufacturing, semiconductor device, final product manufacturing, etc., can solve problems such as staying in research and development, and achieve the effect of improving uniformity and ensuring parallelism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

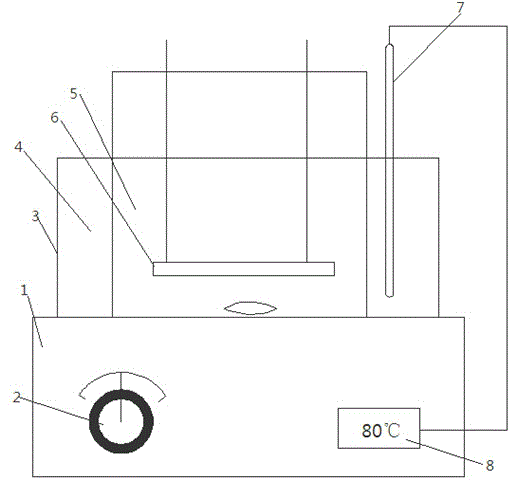

[0049] Preparation of lead salt thin film substrate: first move the deposition solution into the deposition container, and place the deposition container in a water bath with a temperature of 50-100°C, then hang the cleaned substrate in the middle of the deposition solution, at a speed of 30-50rpm Stir and deposit for 2.5 to 3 hours to obtain a lead salt thin film substrate; Example: ① Turn on the magnetic stirrer, adjust and control the temperature of the water bath to 80°C; ② Quantitatively transfer the prepared solution 5 to a 500mL glass deposition container, and put Place the quartz substrate horizontally in the deposition solution; ③ Seal the glass deposition container containing solution 5; heat the deposition container in a water bath and adjust the speed of the magnetic stirrer to 50rpm to start the deposition process; ④ Finish the deposition after 3 hours and take out the substrate end.

[0050] Sensitization treatment: put the lead salt film prepared by chemical ...

example 1

[0055] Select a 30×40mm quartz substrate, clean it with standard cleaning process, dry it with high-purity nitrogen gas and place it on a fixed support.

[0056] 100mL mass concentration of 120g / L potassium hydroxide solution is added into a glass container filled with 190mL distilled water, and 100mL mass concentration of 180g / L lead acetate solution is slowly added at a stirring speed of 300rpm. Add 10 mL of soluble starch solution with a mass concentration of 1 g / L and 100 mL of a sodium selenosulfate solution with a mass concentration of 100 g / L in sequence at a rate of addition, and stir for 10 minutes to obtain 500 mL of a colorless and transparent deposition solution.

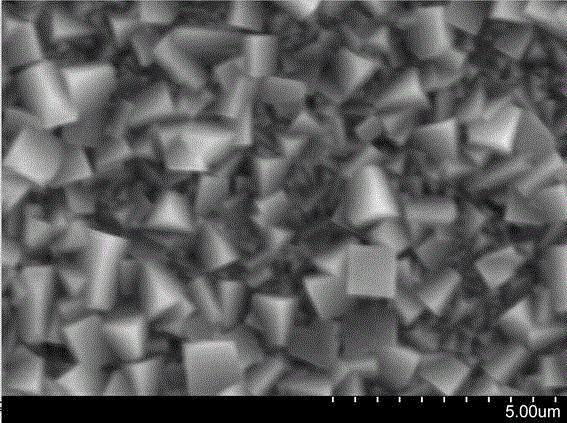

[0057] like figure 1 As shown, the fixed bracket with the substrate was suspended horizontally in the deposition solution, and transferred to a water bath at 75°C and 40 rpm, sealed, and the substrate was taken out after 3 hours to complete the deposition. The lead salt film prepared by chemical bat...

example 2

[0064] Select a 30×40mm ordinary glass substrate, clean it with standard cleaning process, dry it with high-purity nitrogen and place it on a fixed support.

[0065] Measure 100mL of sodium selenosulfate solution with a mass concentration of 205g / L, 100mL of lead acetate solution with a mass concentration of 180g / L, 100mL of potassium hydroxide aqueous solution with a mass concentration of 160g / L, and 10mL of soluble Starch solution and 190 mL of distilled water were used to configure 500 mL of deposition solution in the manner of Example 1.

[0066] The fixed bracket with the substrate was suspended horizontally in the deposition solution, and transferred to a water bath at 80°C and 45 rpm, sealed, and the substrate was taken out after 2.5 hours to complete the deposition.

[0067] Clean the attachment on the substrate, and cut it into a film substrate of 3mm×2mm.

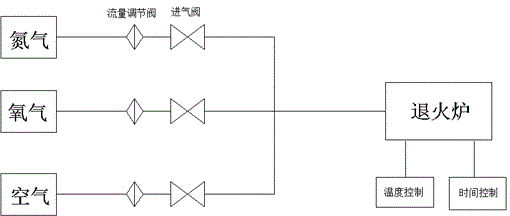

[0068] Put the film substrate into the annealing furnace, check and ensure that the annealing device is wel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com