Halogen-free low-smoke flame-retardant cold resistant rubber sheath material and preparation method thereof

A low-smoke, flame-retardant, rubber sheath technology, which is applied to rubber insulators, plastic/resin/wax insulators, organic insulators, etc., can solve problems such as affecting escape and fire extinguishing, causing death, and losing flame-retardant properties, and achieves overcoming The effect of easy cracking at low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A halogen-free low-smoke flame-retardant low-temperature resistant rubber sheathing material is prepared from the following components by weight:

[0047] 60-80 parts of ethylene-vinyl acetate copolymer, 10-20 parts of ethylene acrylate rubber, 5-20 parts of EPDM rubber, 10-20 parts of superfine magnesium hydroxide, 80-100 parts of aluminum hydroxide, compound 10-20 parts of flame retardant, 5-10 parts of paraffin, 2-5 parts of lubricant, 1-2 parts of dispersant, 1-2 parts of anti-ultraviolet agent, 5-10 parts of cold-resistant plasticizer, 1-2 parts of coupling agent 2 parts, 3~5 parts of auxiliary plasticizer, 3~6 parts of vulcanizing agent, 1~2 parts of accelerator.

[0048] The vulcanizing agent is ethoxylated trimethylolpropane triacrylate (PL400-EO), the accelerator is trimethylolpropane trimethacrylate (XL-60), and the cold-resistant plasticizer is ether ester plasticizer Adipate bis(butoxyethoxyethyl) ester plasticizer, auxiliary plasticizer is linear alkyl pol...

Embodiment 2

[0060] A method for preparing a halogen-free, low-smoke, flame-retardant, and low-temperature resistant rubber sheath material, comprising the following steps:

[0061] (1) Take raw materials by weight proportioning:

[0062] 60-80 parts of ethylene-vinyl acetate copolymer, 10-20 parts of ethylene acrylate rubber, 10-20 parts of EPDM rubber, 10-20 parts of superfine magnesium hydroxide, 80-100 parts of aluminum hydroxide, compound 10-20 parts of flame retardant, 5-10 parts of paraffin, 2-5 parts of lubricant, 1-2 parts of dispersant, cold-resistant plasticizer (ether ester type plasticizer adipic acid bis(butoxyethoxy) B) ester) 5~10 parts, coupling agent 1~2 parts, ethoxylated trimethylolpropane triacrylate 3~5 parts, trimethylolpropane trimethacrylate 1~2 parts;

[0063] The melting point of the lubricant is 50°C, and it is one or more of polyethylene wax, zinc stearate, and stearic acid; the vinyl acetate of the ethylene-vinyl acetate copolymer accounts for the total weigh...

Embodiment 3

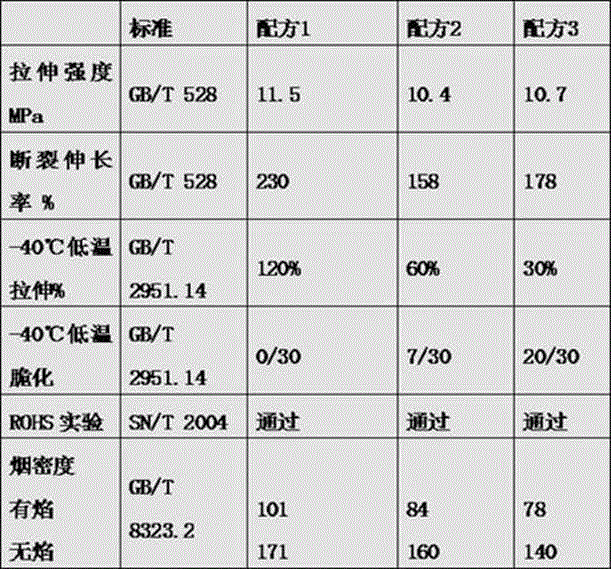

[0070] Three groups of formulas in table 1 are made according to the following steps respectively after being prepared by weight:

[0071] (1) Add ethylene-vinyl acetate copolymer, EPDM rubber, ethylene acrylate rubber, paraffin wax, lubricant, dispersant, and accelerator to the internal mixer in the auxiliary machine and mix for 1 to 3 minutes to obtain Mixture A, lubricant is zinc stearate, stearic acid mixture;

[0072] (2) Then add magnesium hydroxide, aluminum hydroxide, composite flame retardant, coupling agent, and cold-resistant plasticizer to the internal mixer in the lower auxiliary machine for 1-3 minutes of mixing, and the temperature in the internal mixer is controlled at 70- 90°C, 30 seconds before the end of mixing, add vulcanizing agent into the internal mixer to obtain mixture B;

[0073] (3) Mixture A and B obtained by steps (1) and (2) are unloaded to the open mill after mixing;

[0074] (5) Mixtures A and B are put into triangular bags for 3 to 4 times on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com