A kind of mg-ca-sr-zn series magnesium alloy and its preparation method and application

A technology of magnesium alloy and synthesis method, which is applied in the fields of surgery, coating, medical science, etc., and can solve problems such as low corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

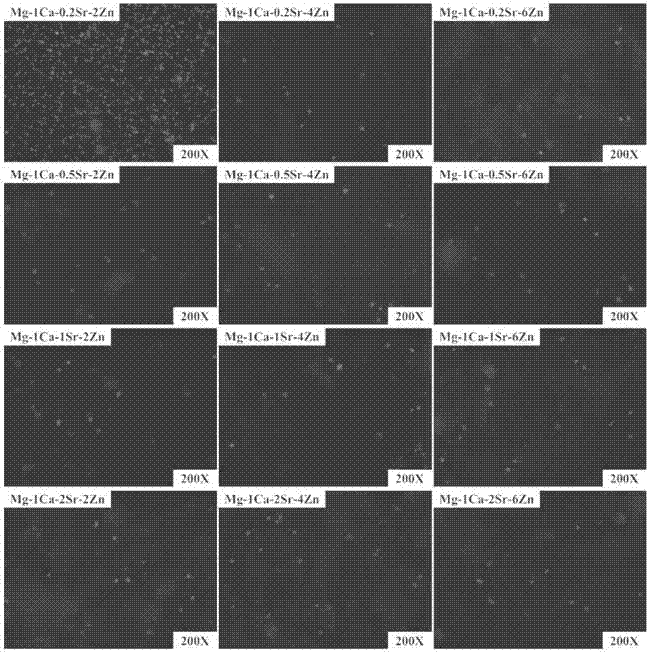

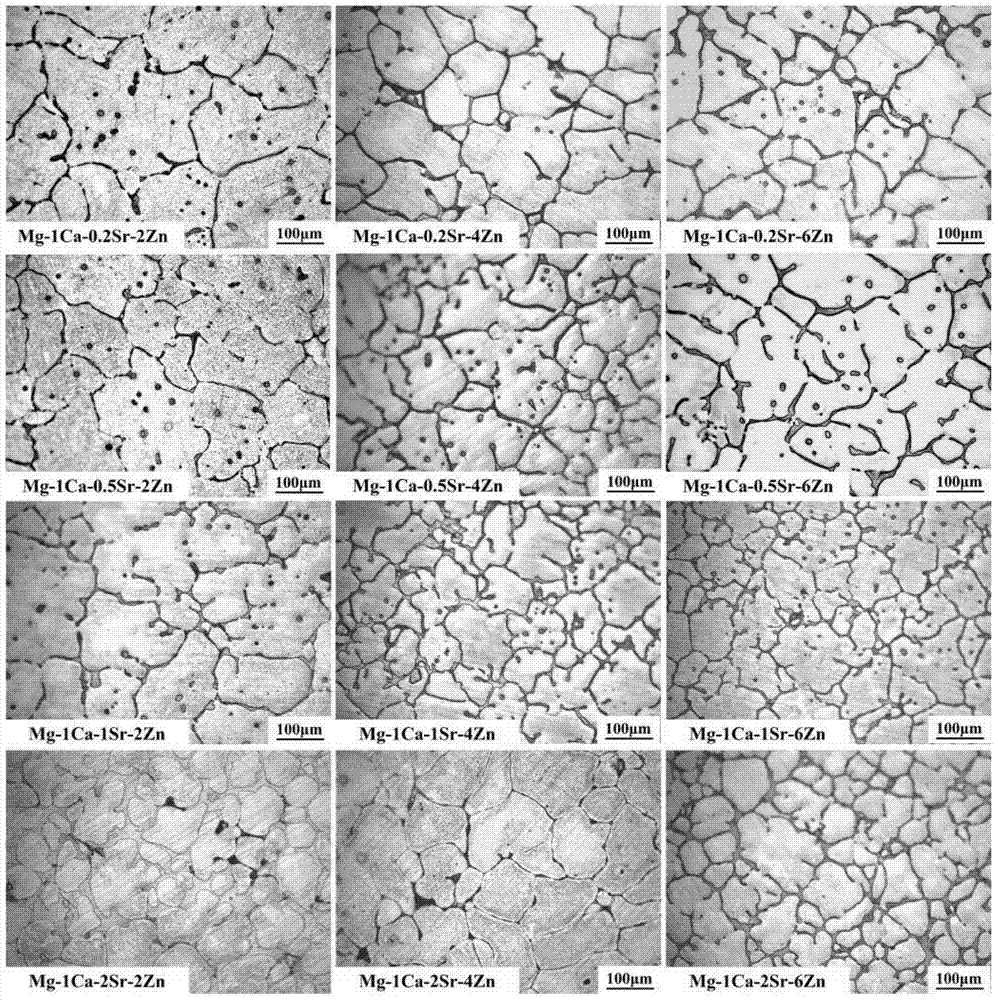

[0089] Embodiment 1, preparation cast state Mg-Ca-Sr-Zn series magnesium alloy

[0090] The test raw materials are pure Mg (99.7wt%), Ca powder (99.8wt%), Sr powder (99.9wt%) and Zn powder (99.5wt%), according to different proportions, as shown in Table 1, at 670 ° C , smelting under the protective atmosphere of Ar gas (99.99%), after the experimental material is fully melted, it is kept for 40 minutes, and then the molten material is poured into the pre- In the designed mold, as-cast Mg-Ca-Sr-Zn magnesium alloys with different proportions were prepared.

[0091] Table 1, the Mg-1Ca-xSr-yZn series magnesium alloy prepared in Example 1

[0092] sample x value y value sample x value y value Sample 1-1 0.2 2 Sample 1-7 1 2 Sample 1-2 0.2 4 Sample 1-8 1 4 Sample 1-3 0.2 6 Samples 1-9 1 6 Sample 1-4 0.5 2 Samples 1-10 2 2 Sample 1-5 0.5 4 Samples 1-11 2 4 Sample 1-6 0.5 6 Sample 1-12 2 6

[...

Embodiment 2

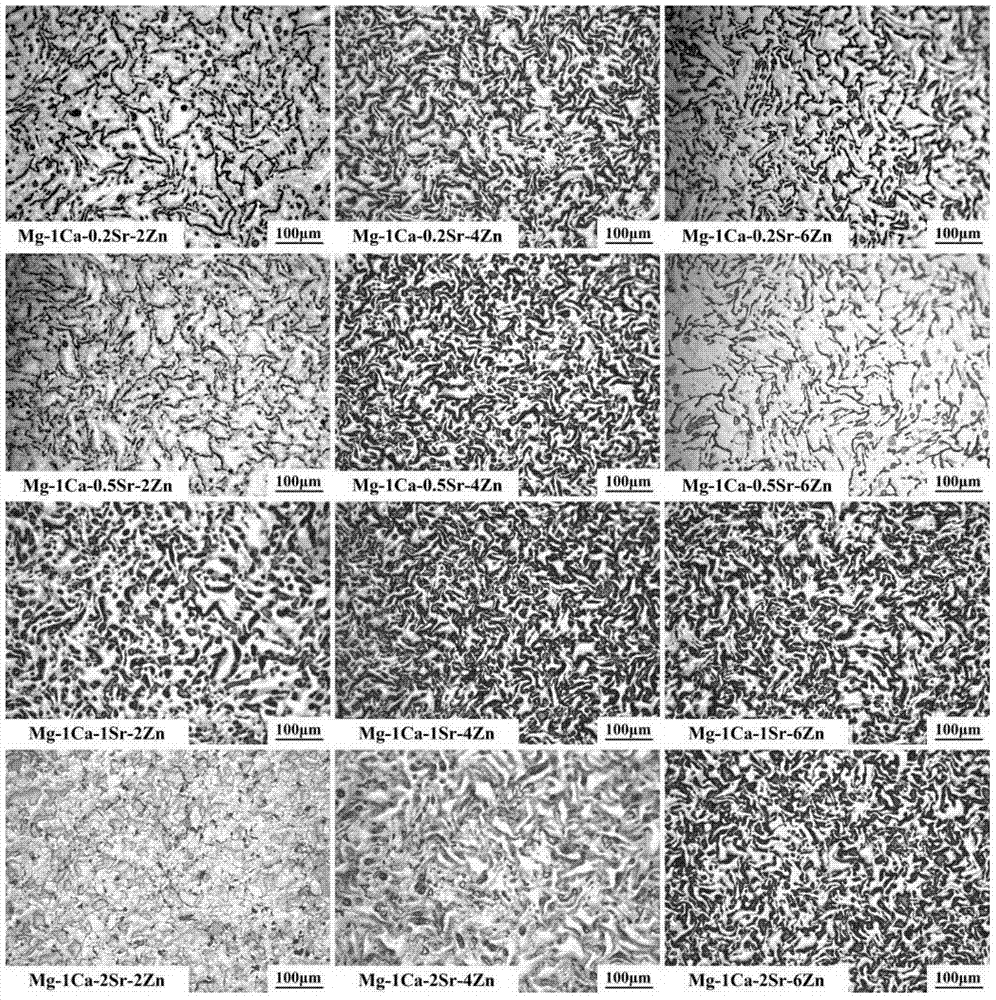

[0095] Embodiment 2, preparation extruded state Mg-Ca-Sr-Zn series magnesium alloy

[0096] Firstly, the as-cast Mg-1Ca-xSr-yZn alloy ingots of different proportions are prepared according to the steps in Example 1 (the proportioning ratio is shown in Table 1), and then all are processed as follows: the ingot is processed into Φ39.6mm× 50mm size, solid solution treatment at 340°C for 4 hours; preheat the ingot to 340°C and keep it warm for 20 minutes, the temperature of the mold and the extrusion cylinder are both 295°C, the extrusion temperature is 320°C, and the extrusion speed is 2mm / s, the extrusion ratio was 16, and the extruded Mg-1Ca-xSr-yZn magnesium alloy (sample 2-12) was prepared, as shown in Table 2.

[0097] Table 2 Example 2 prepared Mg-1Ca-xSr-yZn series magnesium alloy

[0098] sample x value y value sample x value y value Sample 2-1 0.2 2 Sample 2-7 1 2 Sample 2-2 0.2 4 Sample 2-8 1 4 Sample 2-3 0.2 6 Sample...

Embodiment 3

[0101] Embodiment 3, performance test of Mg-Ca-Sr-Zn series magnesium alloy

[0102] (1) Tensile properties at room temperature

[0103] The extruded Mg-Ca-Sr-Zn series magnesium alloy (sample 1-12) prepared in Example 2 was all prepared according to the ASTM-E8-04 tensile test standard, and the SiC sandpaper was polished to 2000# , using a general material tensile testing machine to carry out the tensile test at room temperature, the tensile speed is 0.5mm / min, the results are as follows image 3 shown.

[0104] Depend on image 3 It can be seen that the yield strength of the extruded Mg-Ca-Sr-Zn series magnesium alloy is 100-150 MPa, the tensile strength is 125 MPa-250 MPa, and the elongation at break is 2%-35%. When the Sr content is 0.2wt.% and 1wt.%, the yield strength and tensile strength of the alloy increase with the increase of Zn content, but the elongation at break of the alloy decreases with the increase of Zn content in the alloy . When the Sr content was 0.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com