Soluble polyimide comprising tertiary butyl and morpholinyl structure and preparation method of soluble polyimide

A soluble polyimide and morpholine-based technology, which is applied in the field of soluble polyimide and its preparation, can solve problems such as reduction, and achieve the effects of excellent optical properties, superior heat resistance stability, and low dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

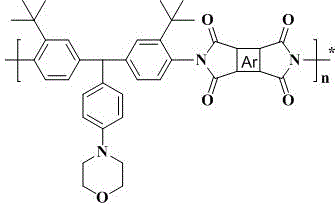

[0028] Add 3,3'-di-tert-butyl-4,4'-diaminophenyl-4'-morpholine to a 50 ml three-necked round-bottomed flask equipped with a mechanical stirrer, reflux condenser, and nitrogen air tube 1.0000 g (2.1201 mmol) of phenylmethane, 0.4624 g (2.1201 mmol) of 3,3′,4,4′-pyromellitic dianhydride, 13.20 g of N,N-dimethylacetamide, at room temperature The reaction was stirred for 24 hours to obtain a precursor polyamic acid solution. Then add the obtained precursor polyamic acid solution to 8ml of acetic anhydride-pyridine mixed solution with a volume ratio of 6:4, stir and react at room temperature for 1 hour, and stir and react at 120°C for 8 hours to obtain a viscous polyimide solution , cooled to room temperature, poured into 500 ml ethanol to precipitate, filtered, and the filtrate was dried in a vacuum oven at 80°C to obtain a light yellow fibrous soluble polyamide containing tert-butyl and morpholino structures. imine. Its structural formula is as follows:

[0029] .

Embodiment 2

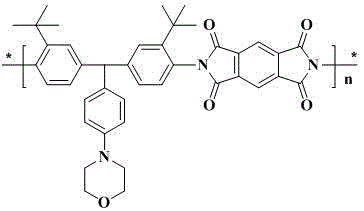

[0031] Add 3,3'-di-tert-butyl-4,4'-diaminophenyl-4'-morpholine to a 50 ml three-necked round-bottomed flask equipped with a mechanical stirrer, reflux condenser, and nitrogen air tube 1.0000 g (2.1201 mmol) of phenylmethane, 0.6238 g (2.1201 mmol) of 3,3′,4,4′-biphenyltetracarboxylic dianhydride, 14.61 g of N,N-dimethylacetamide, at room temperature The reaction was stirred for 24 hours to obtain a precursor polyamic acid solution. Then add the obtained precursor polyamic acid solution into 8ml of acetic anhydride-pyridine mixed solution with a volume ratio of 6:4, stir the reaction at room temperature for 1 h, and stir the reaction at 120°C for 8 h to obtain a viscous polyimide solution. After cooling to room temperature, slowly pour it into 500ml of ethanol to precipitate, filter, put the filtrate into a vacuum drying oven and dry it at 80°C, and then obtain a light yellow fibrous soluble polyimide containing tert-butyl and morpholino structures. amine. Its structural for...

Embodiment 3

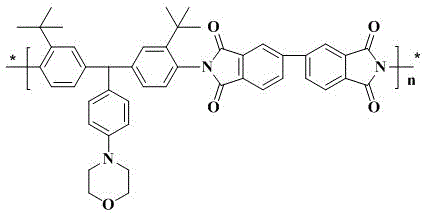

[0034]Add 3,3'-di-tert-butyl-4,4'-diaminophenyl-4'-morpholine to a 50 ml three-necked round-bottomed flask equipped with a mechanical stirrer, reflux condenser, and nitrogen air tube 1.0000 g (2.1201 mmol) of phenylmethane, 0.6577 g (2.1201 mmol) of 3,3′,4,4′-diphenyl ether tetracarboxylic dianhydride, 15.00 g of N,N-dimethylacetamide, in The reaction was stirred at room temperature for 24 hours to obtain a precursor polyamic acid solution. Then, the prepared precursor polyamic acid solution was added to 8 ml of acetic anhydride-pyridine mixed solution with a volume ratio of 6:4, stirred and reacted at room temperature for 1 hour, and then stirred and reacted at 120°C for 8 hours to obtain viscous polyimide solution. After cooling to room temperature, slowly pour it into 500ml of ethanol to precipitate, filter, put the filtrate into a vacuum drying oven and dry it at 80°C, and finally obtain a light yellow fibrous soluble polyamide containing tert-butyl and morpholino structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| carbon residual rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com