Method of preparing electroactive molecule grafted graphene doped conductive polymer electrode materials

A technology of conductive polymers and electroactive molecules, applied in the fields of hybrid capacitor electrodes and hybrid/electric double layer capacitor manufacturing, etc., can solve the problems of improvement, graphene agglomeration, unfavorable energy density, etc., and achieves wide application prospects, simple equipment, The effect of good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

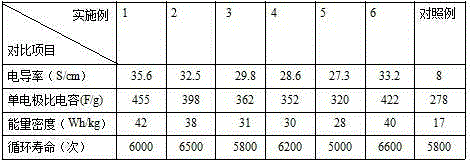

Examples

Embodiment 1

[0019] Example 1 A preparation method of electroactive molecule grafted graphene-doped conductive polymer electrode material, the steps are as follows:

[0020] (1) 1mg 1-aminoanthraquinone grafted graphene (preparation method see: Wu Q, Sun YQ, Bai H, Shi GQ. High-performance supercapacitor electrodes based on graphene hydrogels modified with 2-aminoanthraquinone moieties. Phys. Chem . Chem. Phys., 2011, 13: 11193-11198. The preparation method of 1-aminoanthraquinone grafted graphene is disclosed here, and the implementation of 2-6 method is not disclosed, but the basic preparation principle is the same as this disclosed method, only The difference between reaction time and temperature) was dissolved in 100mL water, stirred and dispersed by ultrasonic waves to form a solution of anthraquinone electroactive molecules grafted graphene (electroactive graphene) with a concentration of 0.01g / L, and set aside.

[0021] (2) Add 99 mg (1.0645 mmol) of aniline (purchased from Sinophar...

Embodiment 2

[0024] Embodiment 2. A preparation method of an electroactive molecule grafted graphene-doped conductive polymer electrode material, which differs from Example 1 in that 1 mg of 1-aminoanthraquinone grafted graphene becomes 5 mg of 1,4-diaminoanthraquinone Grafted graphene, 99mg (1.0645mmol) aniline changed to 0.35g (5.2239mmol) pyrrole, 0.2429g (1.0645mmol) ammonium persulfate changed to 1.6946g (10.4477mmol), -10℃ for 24h and changed to stirring condition at 0 ℃ reaction 18h.

Embodiment 3

[0025] Embodiment 3. A preparation method of electroactive molecule grafted graphene-doped conductive polymer electrode material, which differs from Example 1 in that 1mg 1-aminoanthraquinone grafted graphene becomes 10mg 2,6-diaminoanthraquinone Grafted graphene, 99mg (1.0645mmol) aniline to 0.5g (4.6296mmol) m-phenylenediamine, 0.2429g (1.0645mmol) ammonium persulfate to 5.0055g (18.5184mmol) potassium persulfate, react at -10℃ for 24h Change to stirring conditions and react at 10°C for 18h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com