Method for preparing compound polyvinylidene fluoride super-hydrophobic porous separating membrane

A polyvinylidene fluoride, porous separation membrane technology, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of unsatisfactory application performance and low base membrane porosity, and achieve good permeability , the effect of increasing hydrophobicity, good strength and workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) The quality is respectively: polyvinylidene fluoride of 5g, polyvinyl chloride of 1g, polyethylene glycol of 1g, N,N-dimethylformamide of 93g are mixed evenly, and defoaming obtains film making liquid;

[0031] (2) Immerse the polypropylene non-woven fabric into the film-making solution obtained in step (1) for dip coating, and dip the polypropylene non-woven fabric dipped into the film-making solution through a scraper and then immerse it in a coagulation bath for curing, molding and cleaning ;

[0032] (3) Immerse the film prepared in step (2) into a fluorocarbon polymer emulsion with a mass percentage of 1% for dip coating, take out and remove the excess emulsion adsorbed on the surface, and then dry at 60°C;

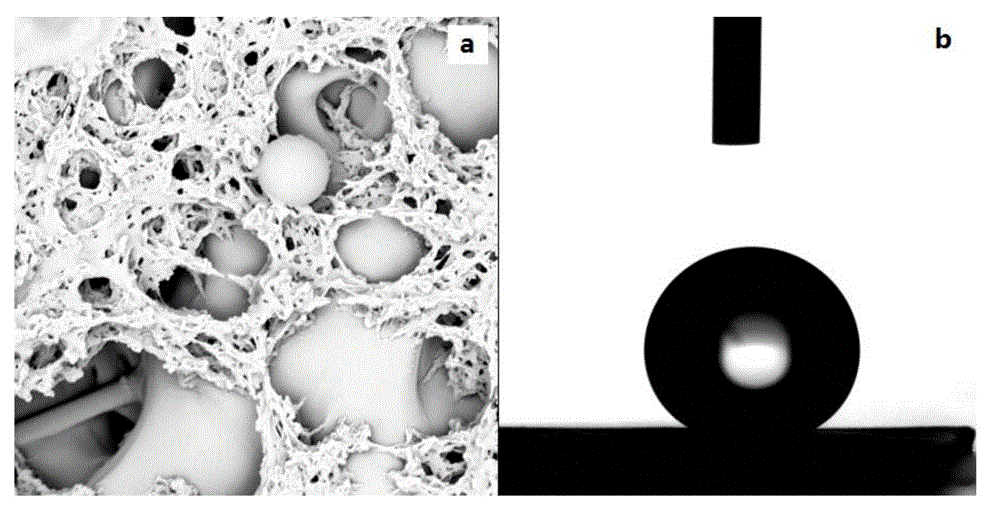

[0033] (4) The membrane prepared in step (3) was heat-treated in a vacuum environment at 80°C for 4 hours, and finally a polyvinylidene fluoride superhydrophobic composite porous separation membrane was obtained, and the static contact angle of the water s...

Embodiment 2

[0035] (1) The quality is respectively: polyvinylidene fluoride of 20g, polyethersulfone of 8g, polyvinylpyrrolidone of 5g, N,N-dimethylacetamide of 67g are mixed uniformly, and defoaming obtains film making solution;

[0036] (2) Immerse the polyethylene non-woven fabric into the film-making solution obtained in step (1) for dip coating, and dip the polyethylene non-woven fabric coated with the film-making solution through a scraper and then immerse it in a coagulation bath for curing, molding and cleaning ;

[0037] (3) Immerse the film prepared in step (2) into a polydimethylsiloxane emulsion with a mass percentage of 2% for dip coating, take out and remove the excess emulsion adsorbed on the surface, and then dry it at 100°C;

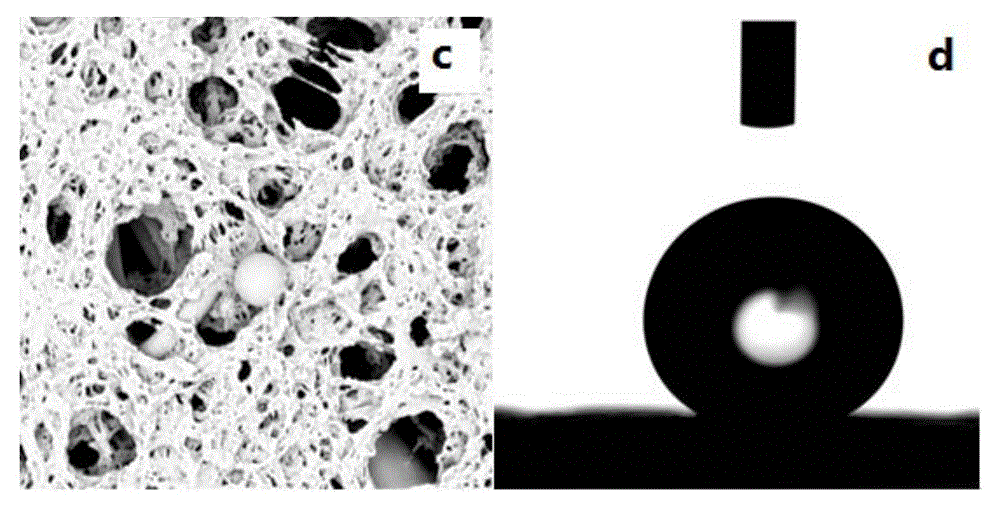

[0038] (4) The membrane prepared in step (3) was heat-treated for 6 hours in a vacuum environment at 50°C, and finally a polyvinylidene fluoride superhydrophobic composite porous separation membrane was obtained, and the static contact angle of the wa...

Embodiment 3

[0040] (1) The quality is respectively: the polyvinylidene fluoride of 10g, the polysulfone of 2g, the poly(styrene-maleic anhydride) copolymer of 2g, the diethylene glycol of 3g, the trimethyl phosphate of 70g, 13gN, N -Dimethylacetamide is mixed evenly, and degassing to obtain a film-making solution;

[0041] (2) Immerse the polypropylene / polyethylene composite non-woven fabric into the film-making solution obtained in step (1) for dip coating, and then immerse the non-woven fabric dipped in the film-making solution through a scraper and then immerse it in a coagulation bath for curing and molding and cleaning;

[0042] (3) Immerse the film prepared in step (2) into a fluorocarbon polymer emulsion with a mass percentage of 5% for dip coating, take out and remove the excess emulsion adsorbed on the surface, and then dry at 90°C;

[0043] (4) The membrane prepared in step (3) was heat-treated for 5 hours in a vacuum environment at 70° C. to finally obtain a polyvinylidene flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com