Preparation method for carboxylic acid type polyfluorene/titanium dioxide nano-hybrid materials

A nano-hybrid material, titanium dioxide technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of design and chemical synthesis complexity and limitations, and achieve the effect of good film formation and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

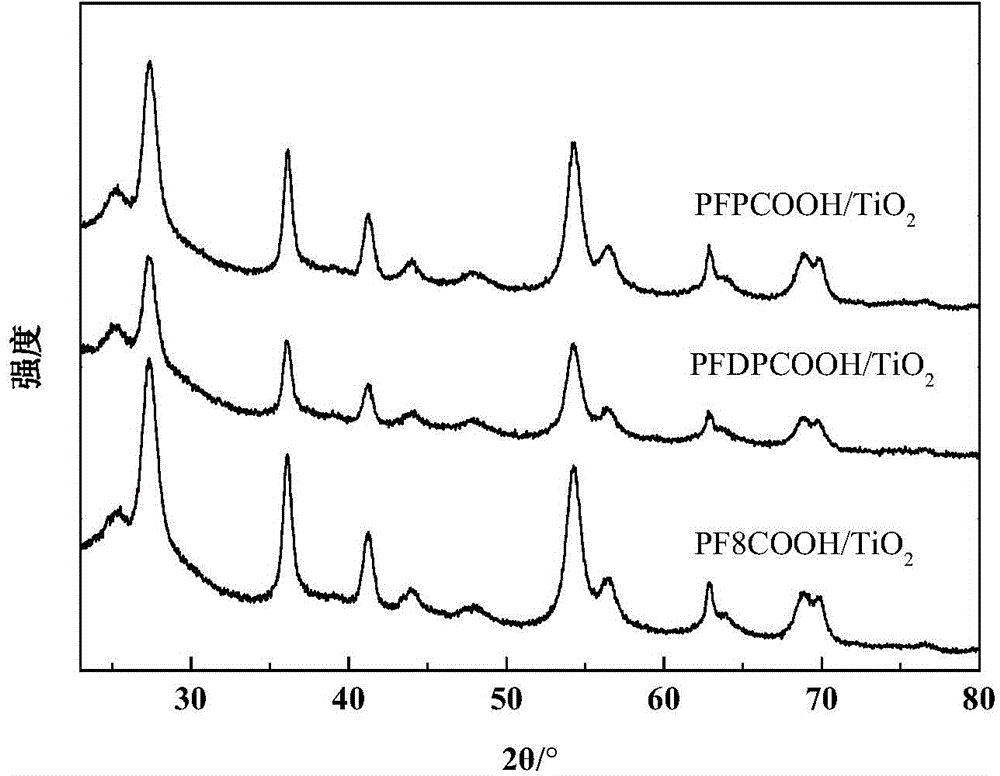

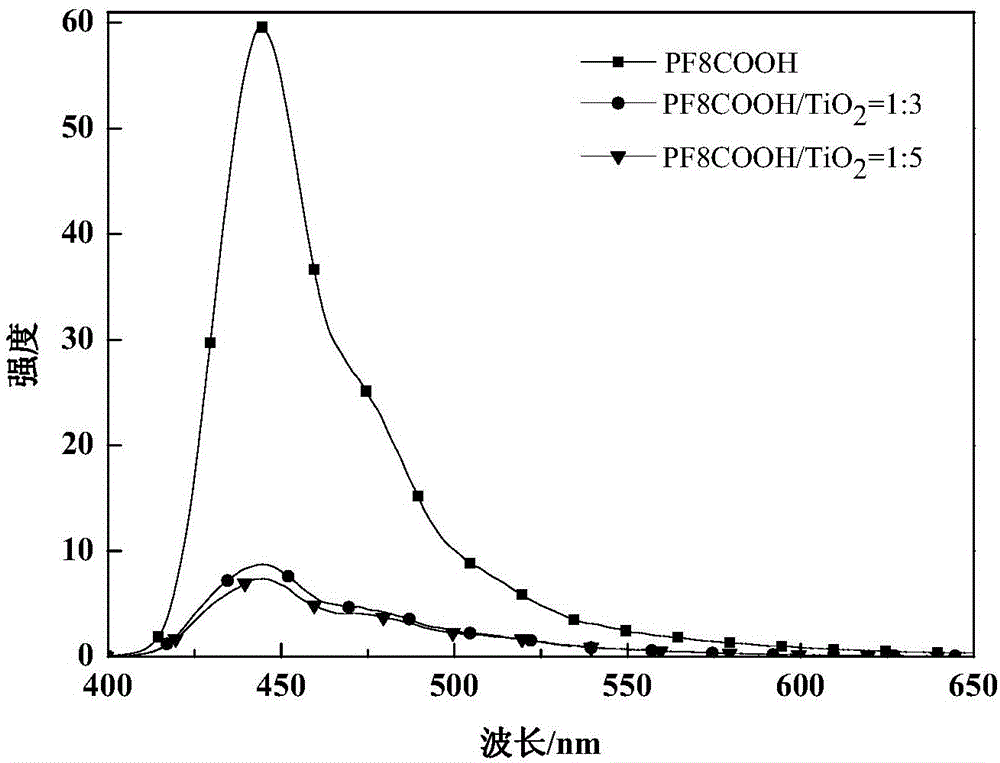

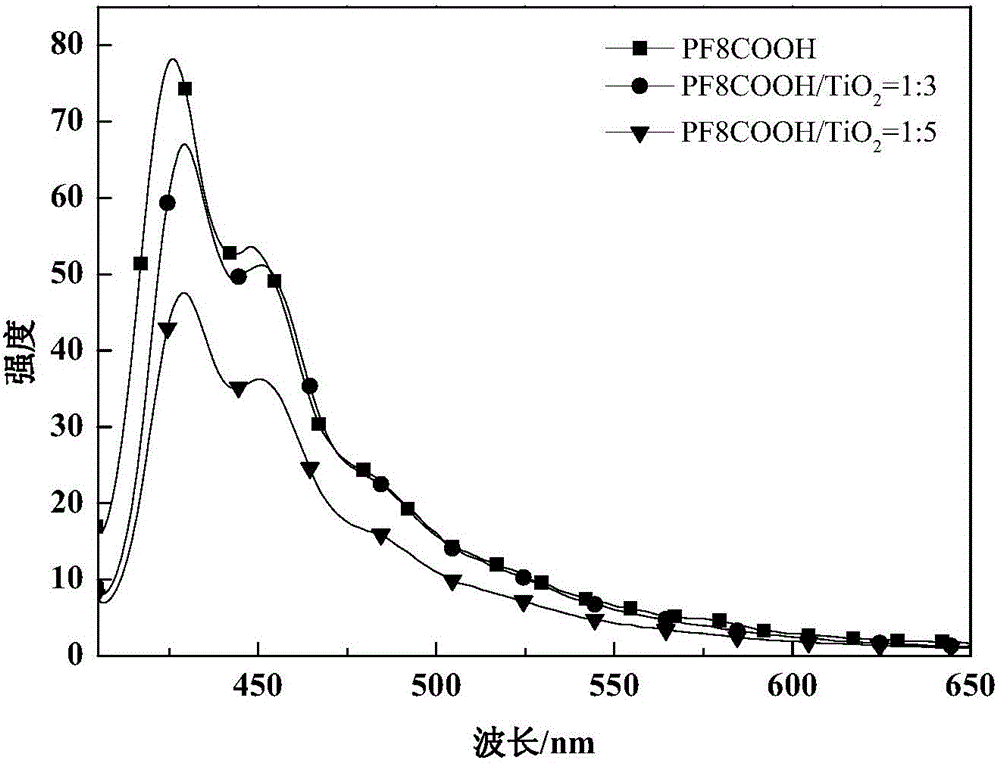

[0043] The carboxylic acid type polyfluorene selected in this embodiment is poly[9,9-dioctylfluorene-9,9-bis(propionyl)fluorene](PF8FCOOH), and its structure is as follows:

[0044]

[0045] Among them, n=15.

[0046] (1) Synthesis of 2,7-dibromo-9,9-bis(propionyl)fluorene

[0047] Add 3.24g 2,7-dibromofluorene, 0.25g tetrabutylammonium bromide, and 25mL DMSO to a 100mL three-necked flask equipped with a thermometer and a magnetic stirrer, and inject 5mL of 50% mass fraction of hydroxide under a nitrogen atmosphere. Potassium aqueous solution was reacted at 30°C for 0.5h, then 1.584g of acrylic acid was added, and the reaction was continued for 6h. After the reaction, the reaction solution was poured into a beaker equipped with 200mL deionized water, extracted with dichloroethane until the water layer was colorless, separated, kept the water layer, the pH of the water layer was adjusted to acidic, and the product was precipitated. Filter and dry in a blast oven at 60°C to...

Embodiment 2

[0053] The carboxylic acid type polyfluorene selected in this embodiment is poly[1,1′-biphenyl-9,9-bis(propionyl)fluorene](PFDPCOOH), and its structure is as follows:

[0054]

[0055] Among them, n=12.

[0056] (1) Synthesis of 2,7-dibromo-9,9-bis(propionyl)fluorene

[0057] Add 3.24g 2,7-dibromofluorene, 0.25g tetrabutylammonium bromide, and 25mL DMSO to a 100mL three-necked flask equipped with a thermometer and a magnetic stirrer, and inject 5mL of 50% mass fraction of hydroxide under a nitrogen atmosphere. Potassium aqueous solution was reacted at 30°C for 0.5h, then 1.892g of methyl acrylate was added, and the reaction was continued for 6h. After the reaction, the reaction solution was poured into a beaker equipped with 200mL deionized water, extracted with dichloroethane until the water layer was colorless, separated, kept the water layer, the pH of the water layer was adjusted to acidic, and the product was precipitated. Filter and dry in a blast oven at 60°C to ob...

Embodiment 3

[0063] The carboxylic acid type polyfluorene selected in this embodiment is poly[1,4-phenyl-9,9-bis(propionyl)fluorene] (PFPCOOH), and its structure is as follows:

[0064]

[0065] Among them, n=14.

[0066] (1) Synthesis of 2,7-dibromo-9,9-bis(propionyl)fluorene

[0067] Add 3.24g 2,7-dibromofluorene, 0.25g tetrabutylammonium bromide, and 25mL DMSO to a 100mL three-necked flask equipped with a thermometer and a magnetic stirrer, and inject 5mL of 50% mass fraction of hydroxide under a nitrogen atmosphere. Potassium aqueous solution was reacted at 30°C for 0.5h, then 3.146g of dimethylaminoethyl acrylate was added, and the reaction was continued for 6h. After the reaction, the reaction solution was poured into a beaker equipped with 200mL deionized water, extracted with dichloroethane until the water layer was colorless, separated, kept the water layer, the pH of the water layer was adjusted to acidic, and the product was precipitated. Filter and dry in a blast oven at 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com