Electrode for lithium secondary battery, lithium secondary battery using same and method for manufacturing same

A lithium secondary battery and electrode technology, which is applied to the electrode of inorganic particles, lithium secondary battery and its preparation field, can solve the problems of low interface characteristics, uneven electrolyte distribution, and reduced lifespan, so as to improve interface characteristics and prolong lifespan And high-efficiency discharge characteristics, the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

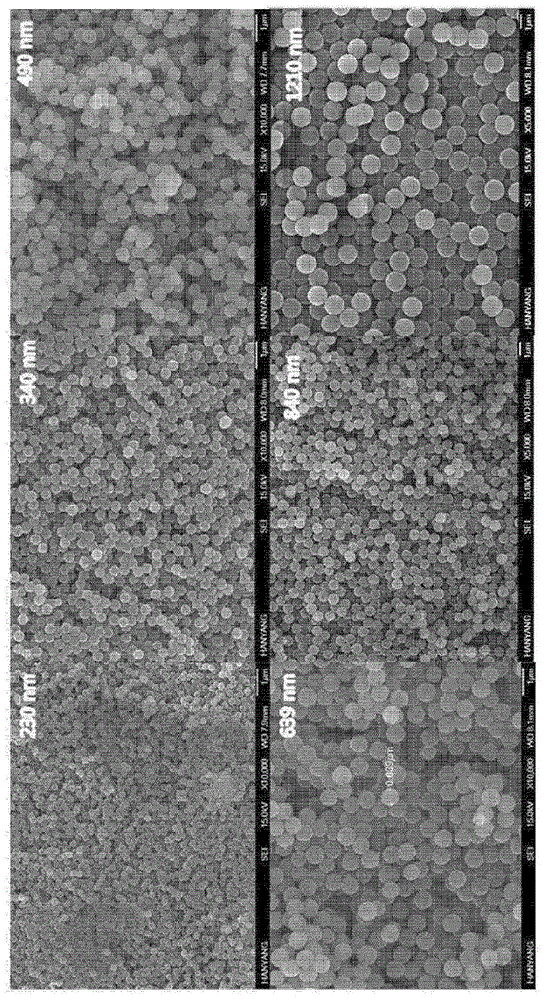

[0069] At room temperature, 150 ml of pure water was put into the reactor, and 10 ml of vinyltrimethoxysilane was measured to be slowly dropped into the reactor, and stirred. Vinyltrimethoxysilane became transparent after being completely dispersed in purified water, added to 0.1 ml of ammonia solution and stirred at room temperature for 12 hours to conduct condensation polymerization. After the reaction was completed, a precipitate was prepared from the resulting liquid using a centrifuge. The precipitate was washed three or more times with methanol and filtered to remove unreacted materials and impurities. The prepared precipitate was dried in a vacuum oven at 70° C. for 1 hour to obtain silica, which had a size of 1.2 μm and was capable of being polymerized.

[0070] In addition, silica capable of being polymerized is synthesized in various sizes using the methods described above. The nitric acid solution is first introduced into purified water and reacted.

[0071] The ...

experiment example 2

[0077] Inorganic materials other than silica are reacted with vinyltriethoxysilane or 3-(triethoxysilyl)propyl methacrylate to introduce vinyl or acrylate groups into various inorganic on the surface of the particles.

[0078]Aluminum isopropoxide is dispersed in water and stirred. A nitric acid solution was added as a catalyst, and reacted at 90° C. for 6 hours, thereby forming alumina particles. Then, after introducing vinyltriethoxysilane or 3-(triethoxysilyl)propylmethacrylate and stirring at 90°C for 1 hour, the precipitate was washed to obtain the final product

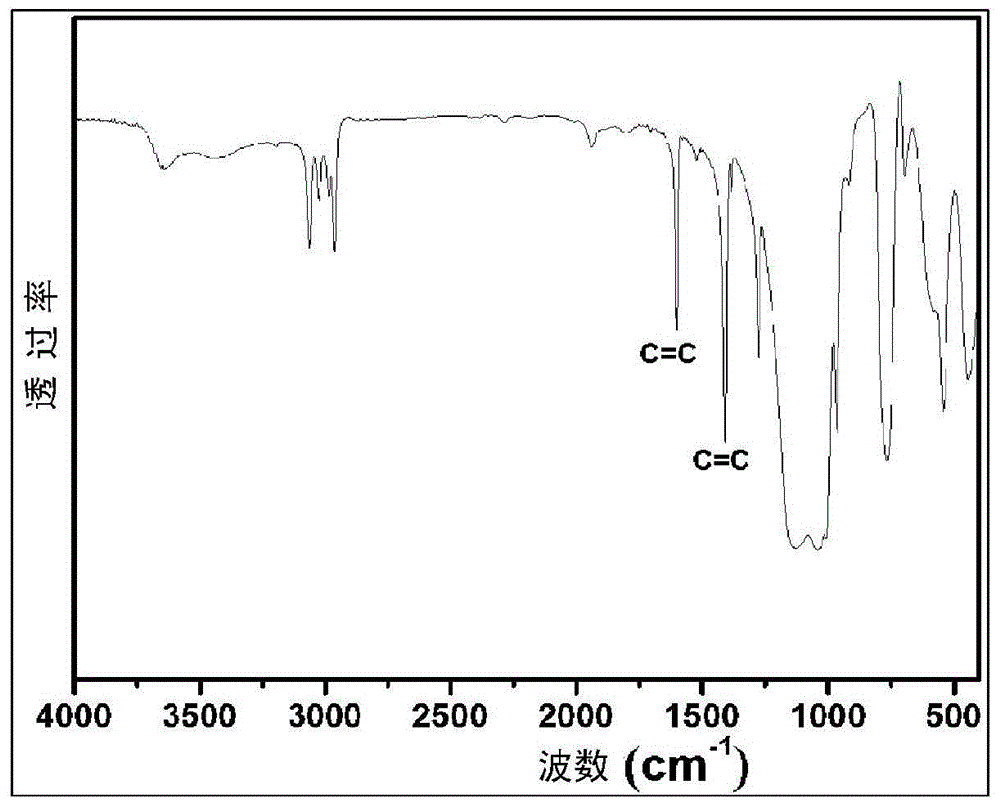

[0079] Figure 4 is the FT-IR spectrum of the silica particles prepared in Experimental Example 2. It should be understood that there exist at about 1,630cm -1 -1,400cm -1 Vinyl groups that can be synthesized with alumina particles in the infrared absorption range.

[0080] In the same way, polymeric organic functional groups are introduced into various inorganic materials, such as titanium, germanium and / ...

experiment example 3

[0083] Negative electrodes for lithium secondary batteries were prepared using natural graphite. The DAG-A active material, which is natural graphite, and the silica having vinyl groups synthesized in Experimental Example 1 were dispersed by dry mixing. KS6 and Super-P (which is a conductive material), binder PVdF, and solvent NMP were introduced to prepare electrode paste. The electrode slurry was coated on an aluminum foil, and the solvent was taken out of a vacuum oven at 120° C., thereby completing an electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com