Preparation and application of aptamer-magnetic nanoparticle used for enrichment and separation of aflatoxin B1

A technology of magnetic nanoparticles and aflatoxin, which is applied in the field of purification and treatment process of aflatoxin B1 samples, can solve the problems of low separation efficiency, complicated purification and separation operations, etc., and achieves the effect of strong selectivity and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

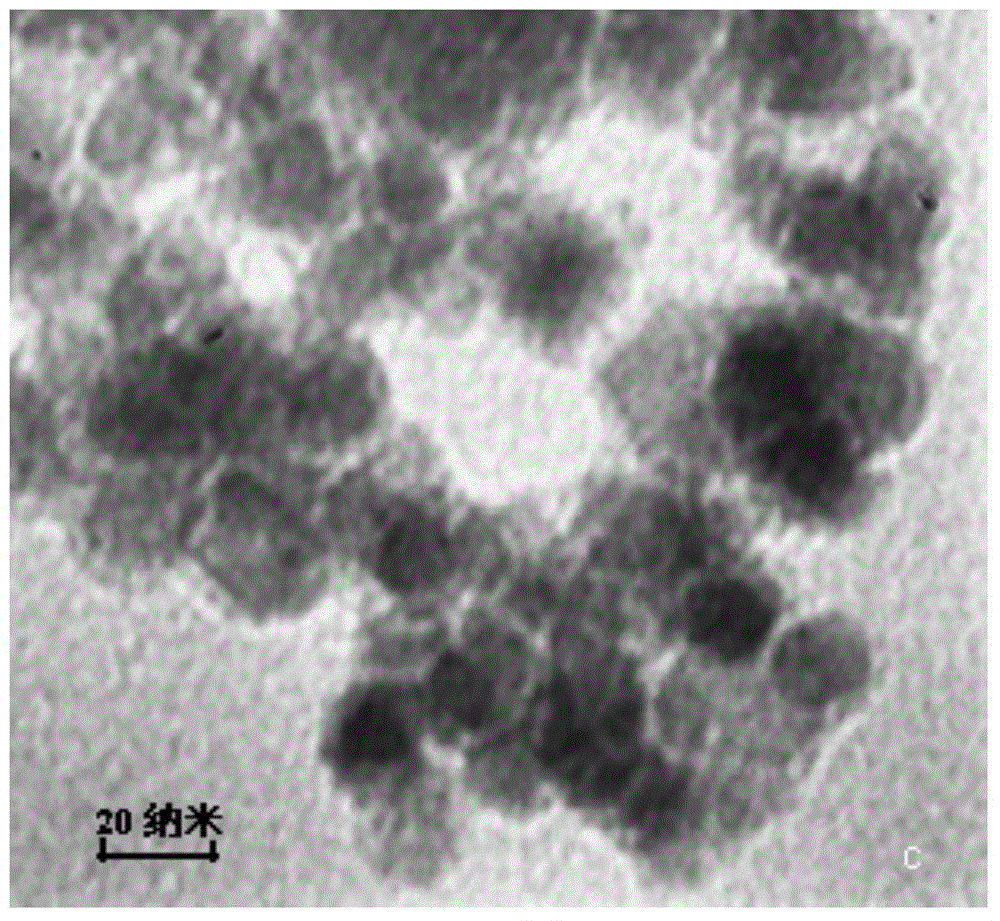

[0036] The method for preparing the aflatoxin B1 aptamer-magnetic nanoparticle complex comprises the following steps:

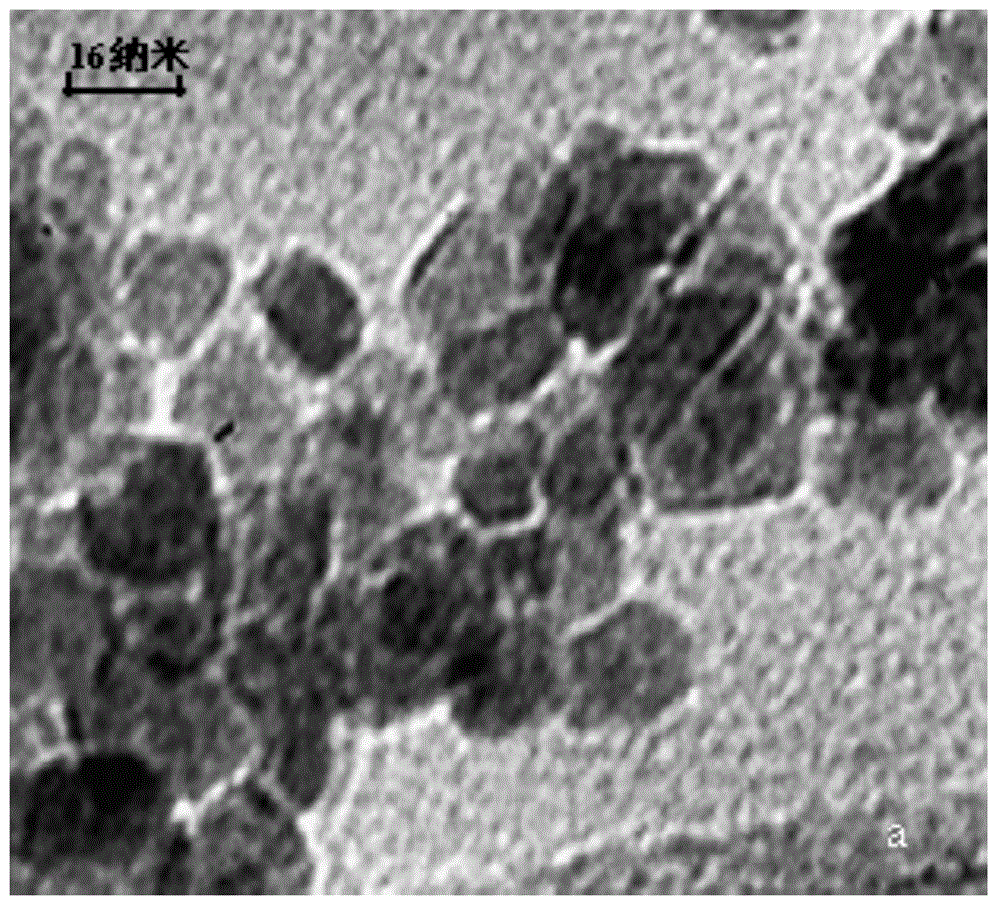

[0037] (1) Preparation method of inner core layer of magnetic nanoparticles

[0038] FeCl 3 ·6H 2 O and FeCl 2 4H 2 O was dissolved in 160 mL of 0.1 mol / L hydrochloric acid solution at a molar ratio of 2:1. Transfer the mixed solution into a 250mL flask, stir vigorously for 30min, slowly add 5mol / L NaOH solution dropwise at 40°C, adjust the pH to 10-11, raise the temperature to 60°C, and age for 2 hours. The whole process is carried out under the protection of nitrogen. The magnetic nanoparticles were washed to neutral with deionized water, and the magnetic nanoparticles were freeze-dried.

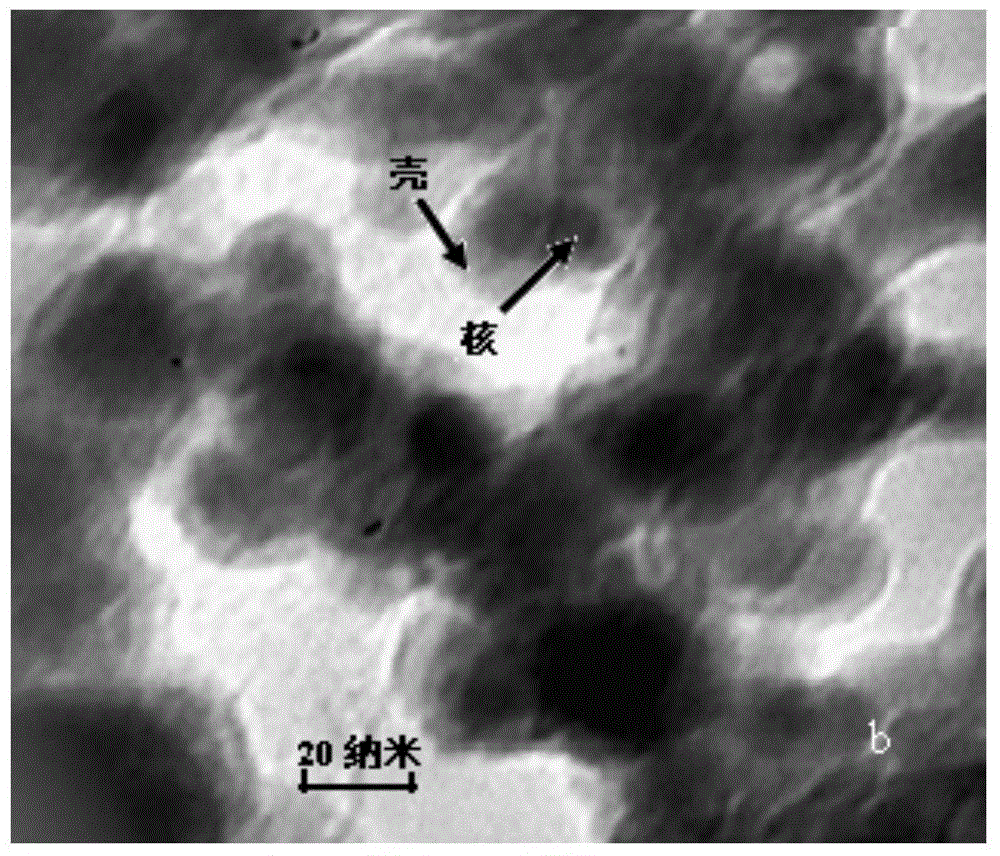

[0039] (2) Preparation method of magnetic nanoparticle silanization layer

[0040] Take by weighing 200mg of Fe after step (1) freeze-drying 3 o 4 Add 5-15 mL of toluene solution containing 5% 3-(2,3-glycidoxy)propyltrimethoxysilane (volume fraction) to the nanopa...

Embodiment 2

[0046] The aflatoxin B1 aptamer-magnetic nanoparticle extraction method for aflatoxin B1 in a wheat sample comprises the following steps:

[0047] Add 1.0 μg / kg, 2.0 μg / kg, and 5.0 μg / kg aflatoxin B1 to the blank wheat flour, add 5 in parallel, and perform HPLC-FLD analysis after the following steps (1) to (3). The obtained results are shown in Table 1, and the measured recovery rate all reaches more than 80%, and the relative standard deviation is less than 10%, indicating that this nanomaterial is suitable for the purification of aflatoxin B1 in the actual sample of wheat flour;

[0048] (1) Weigh about 50% wheat flour, add 10% water / acetonitrile solution (4:6, v / v), vortex mix for 2min, ultrasonicate for 15min, take 1mL supernatant after standing, and dilute to 10mL with PBS buffer.

[0049] (2) Add the aptamer-magnetic nanoparticle complex containing 10 mg into the solution in step (1), and shake at 37° C. for 30 min. After the reaction, the supernatant was discarded unde...

Embodiment 3

[0056] Establishment of HPLC-FLD evaluation method for aflatoxin B1:

[0057] Liquid phase conditions: detection conditions are:

[0058] Chromatographic column: C18, 4.6×150mm, 5μm, or equivalent;

[0059] Column temperature: 30°C;

[0060] Mobile phase: acetonitrile + methanol + water (13+12+75);

[0061] Flow rate: 1.0mL / min;

[0062] Injection volume: 20.0μL;

[0063] Elution method: isocratic elution;

[0064] Fluorescence detection conditions: excitation wavelength, 365nm, emission wavelength, 440nm.

[0065] Take 50.0μg / L aflatoxin B1 standard solution to make series concentration (1.0, 2.0, 5.0, 10.0, 20.0μg / L), add 20.0μL, HLPC-FLD analysis. Fit it linearly with concentration, the linear equation is Y=1.16×10 6 -2.91×10 6 (X, μg / L; R=0.9906).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com